Punching mould of LCD (liquid crystal display) flat-panel display back plane bevel edge convex packet and punching method

A flat-panel display and stamping die technology, applied in the field of stamping dies, can solve problems such as large span, great influence on product distortion and local rebound index, and inability to control product distortion and local rebound index well, so as to reduce distortion , the effect of avoiding the phenomenon of root collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

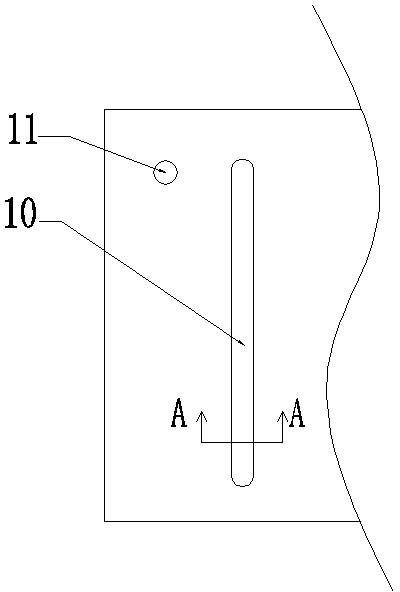

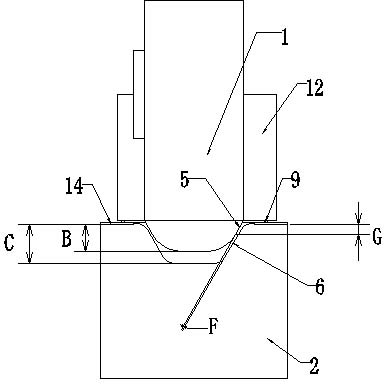

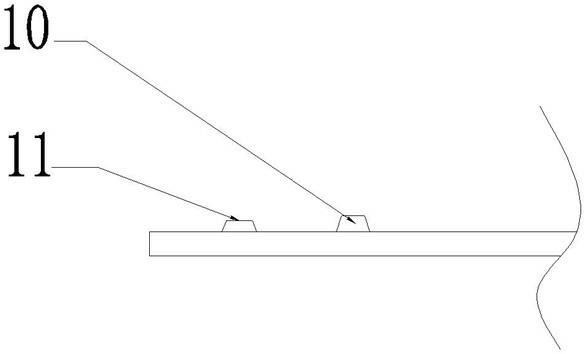

[0030] It should be noted that since both ends of the hypotenuse convex hull 10 are arc-shaped, it is special, so image 3 , Figure 4 It is a schematic diagram of the cross-sectional structure, and the cross-sections at the positions of the respective modules are the same as figure 1 The position of the A-A section in the corresponding, that is image 3 , Figure 4 The cross-sectional structure shown is the cross-sectional structure at the position shown in the A-A section of the processed hypotenuse convex hull 10 other than both ends, and the shown section is parallel to the A-A section.

[0031] refer to figure 1 and figure 2 As shown, the stamping die of the present invention mainly includes two modules: a first module and a second module.

[0032] Among them, refer to image 3 As shown, the first die set includes: a first pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com