Casting machine and casting machine valve

A technology of pouring machine and valve, applied in the direction of transportation and packaging, cocoa, confectionery, etc., to achieve the effect of large flow and good closing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

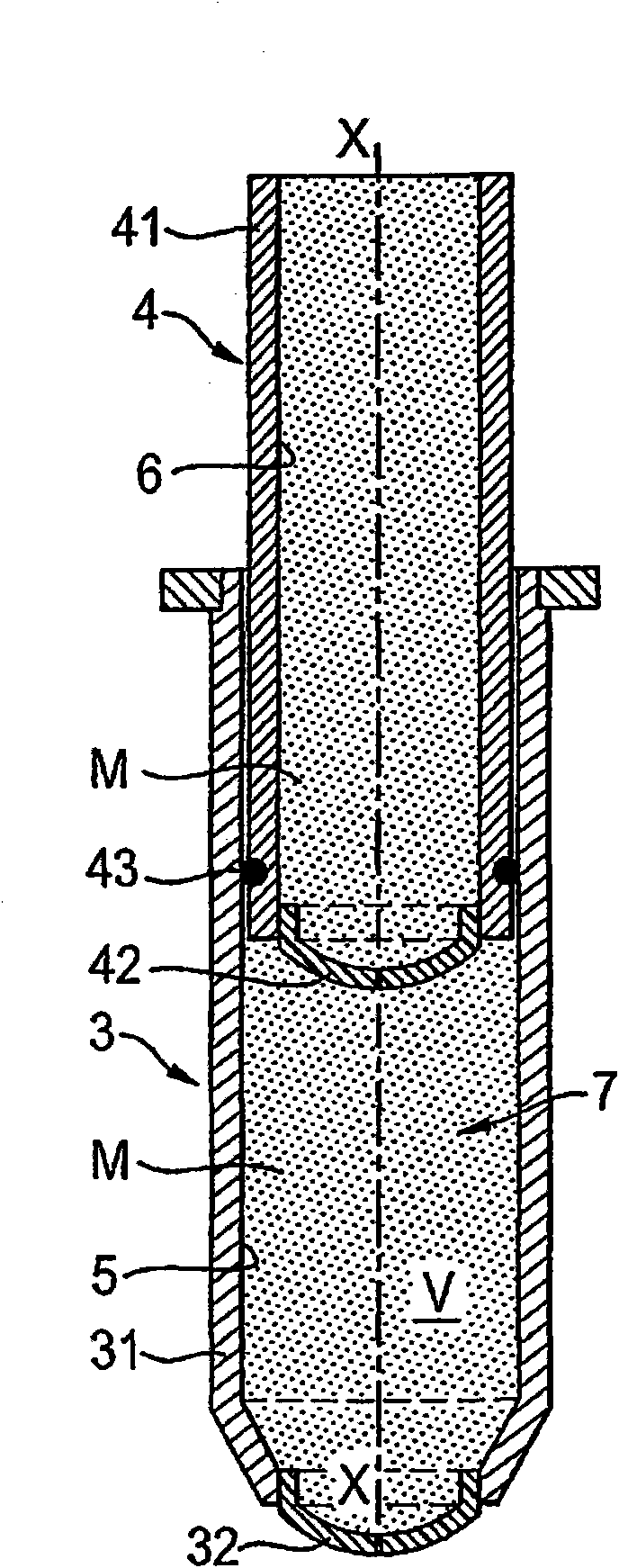

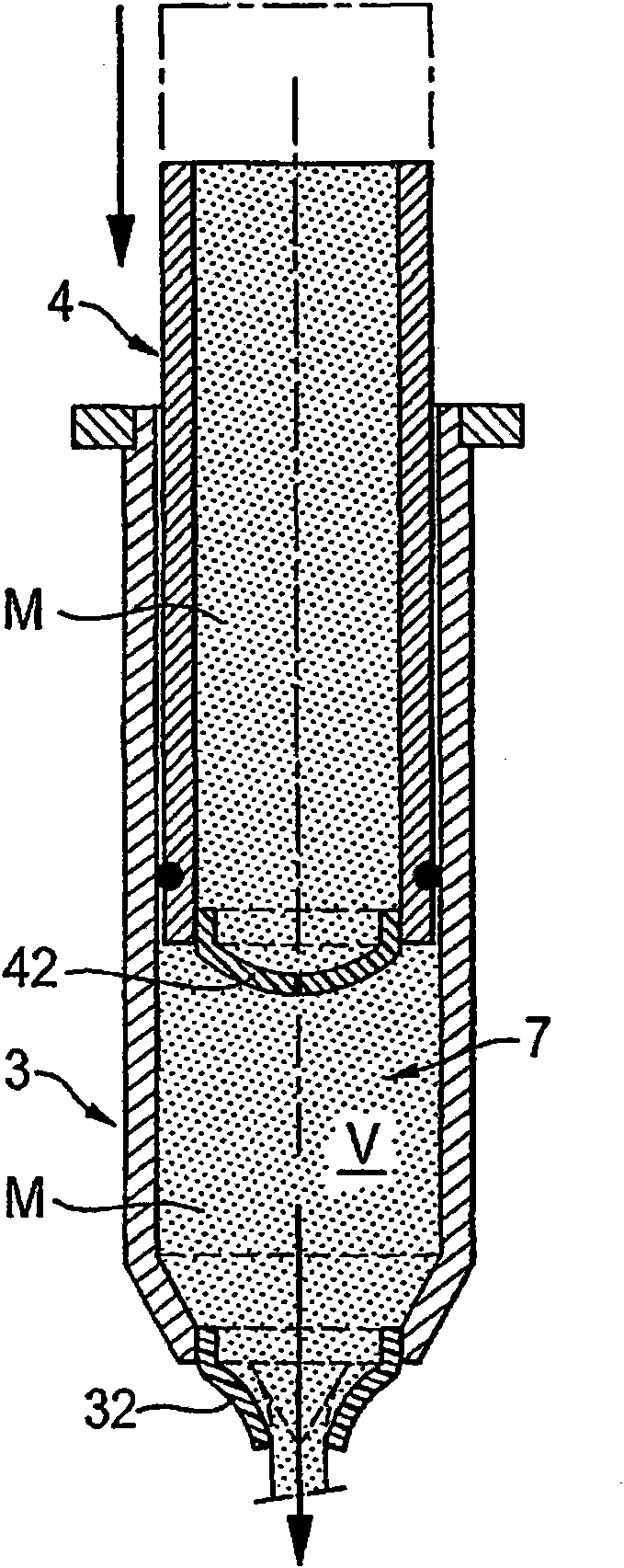

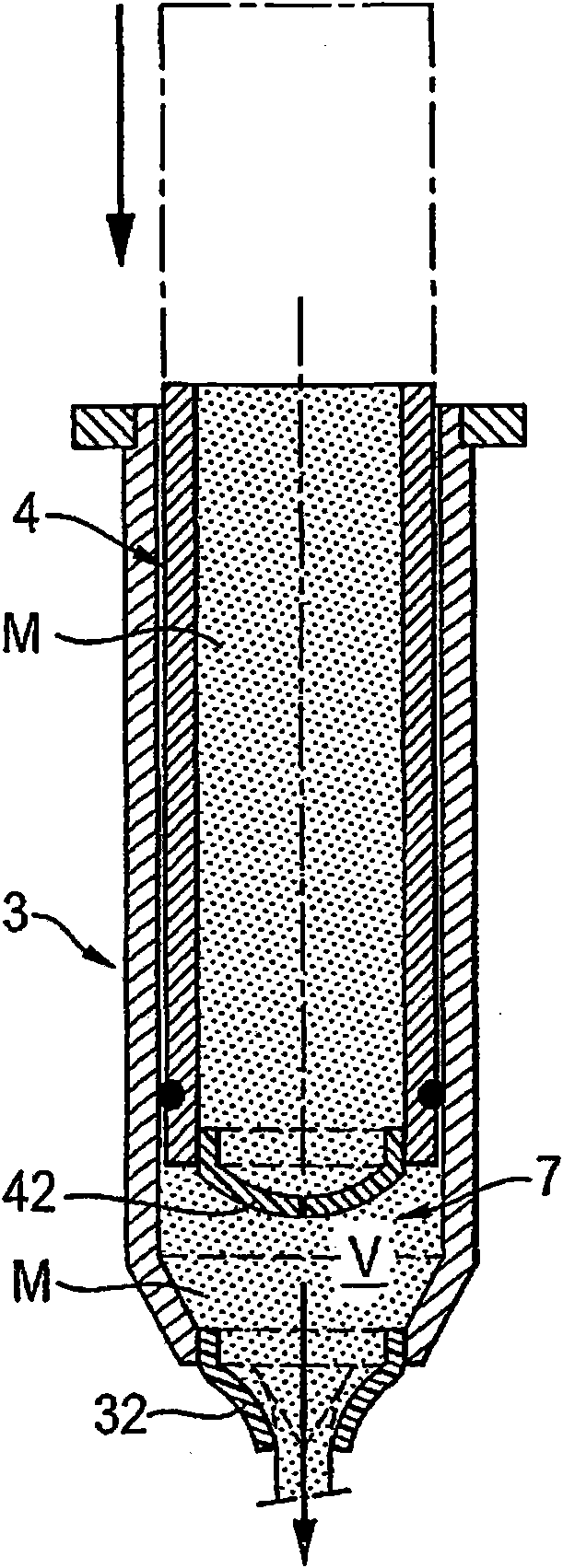

[0061] according to figure 1 A configuration of a dosing unit 3 , 4 is shown, which has a lower valve block 3 and an upper valve block 4 . The dosing unit 3, 4 is an essential component of the pressure generating device according to the invention.

[0062] The lower valve block 3 contains a plurality of lower valve passages 5 arranged side by side and parallel to each other, the cross-section of which is preferably circular. Each lower valve channel 5 is delimited by a channel wall 31 which is preferably cylindrical. At the lower end of a lower valve passage 5 there is a lower valve 32 and at the upper end of the lower valve passage 5 there is an upper valve 42 . Via the channel wall 31 , the lower valve 32 and the upper valve 42 define a dosing chamber whose volume V is variable and is formed by the variable section of the lower valve channel 5 .

[0063] The upper valve block 4 also includes a plurality of upper valve passages 6 arranged side by side and parallel to each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com