Enhanced thermoplastic composite pipe buckling and pressing joint and buckling and pressing connection method

A technology for enhancing thermoplasticity and connection method. It is applied in the direction of pipe connection arrangement, pipe/pipe joint/pipe fitting, mechanical equipment, etc. It can solve the problems of poor stability and reliability, easy loosening, limited pressing force, etc. Convenience, improved pressing force, increased contact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

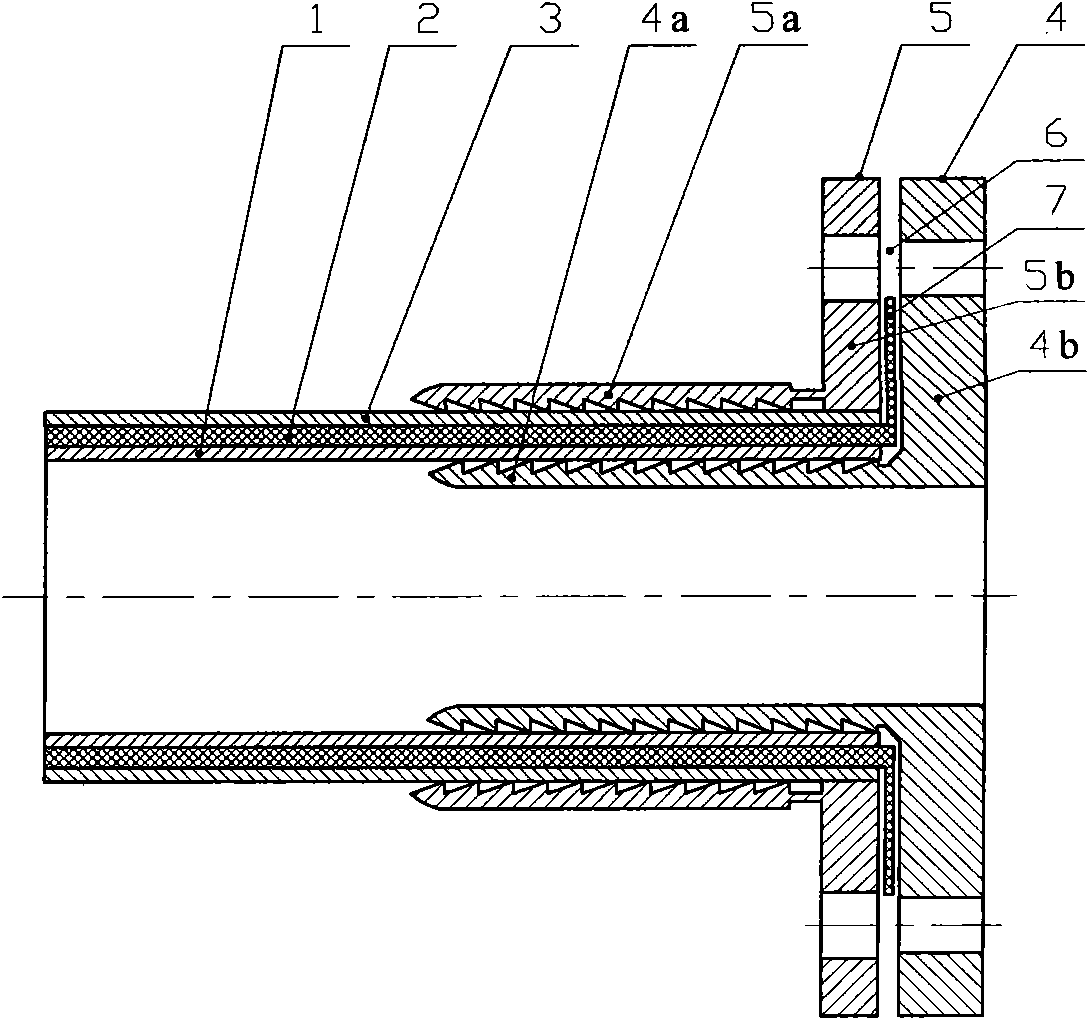

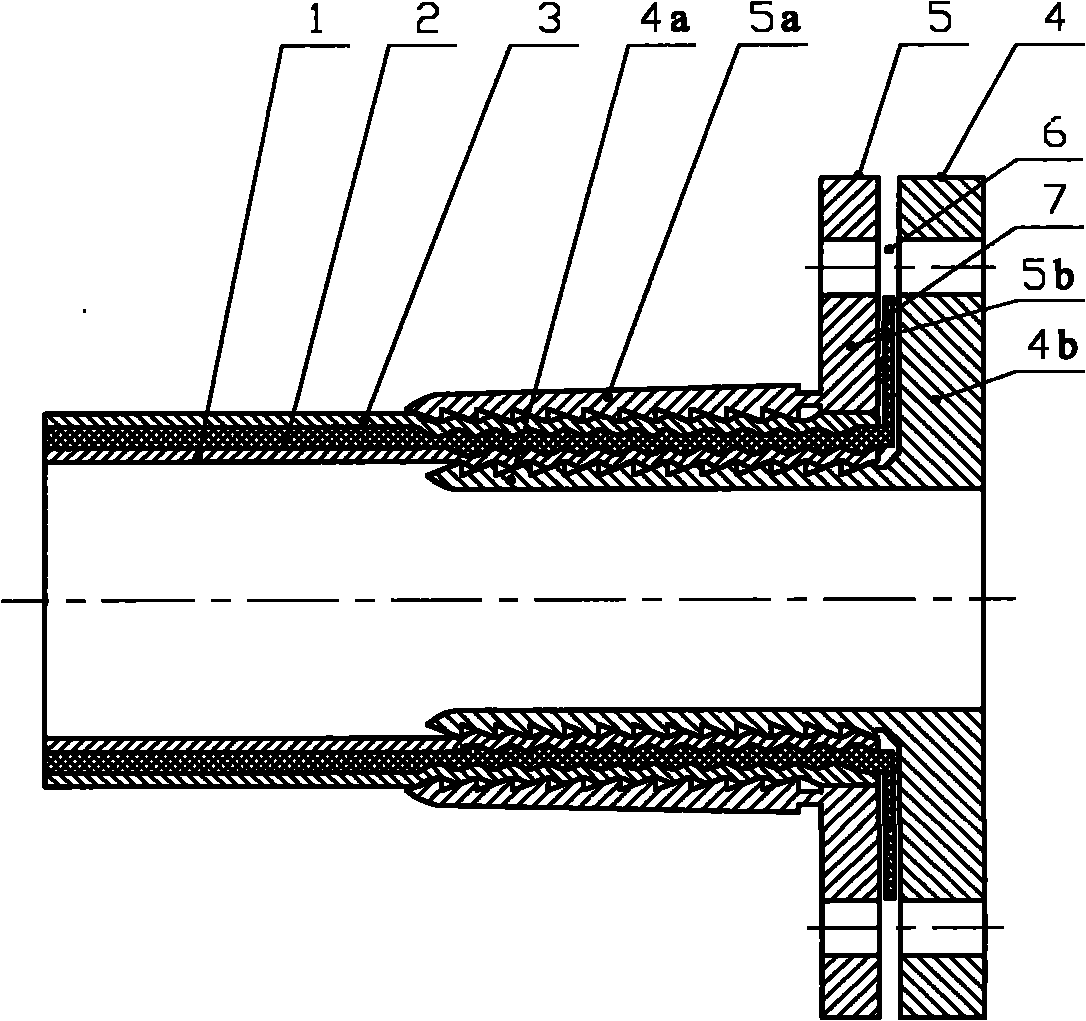

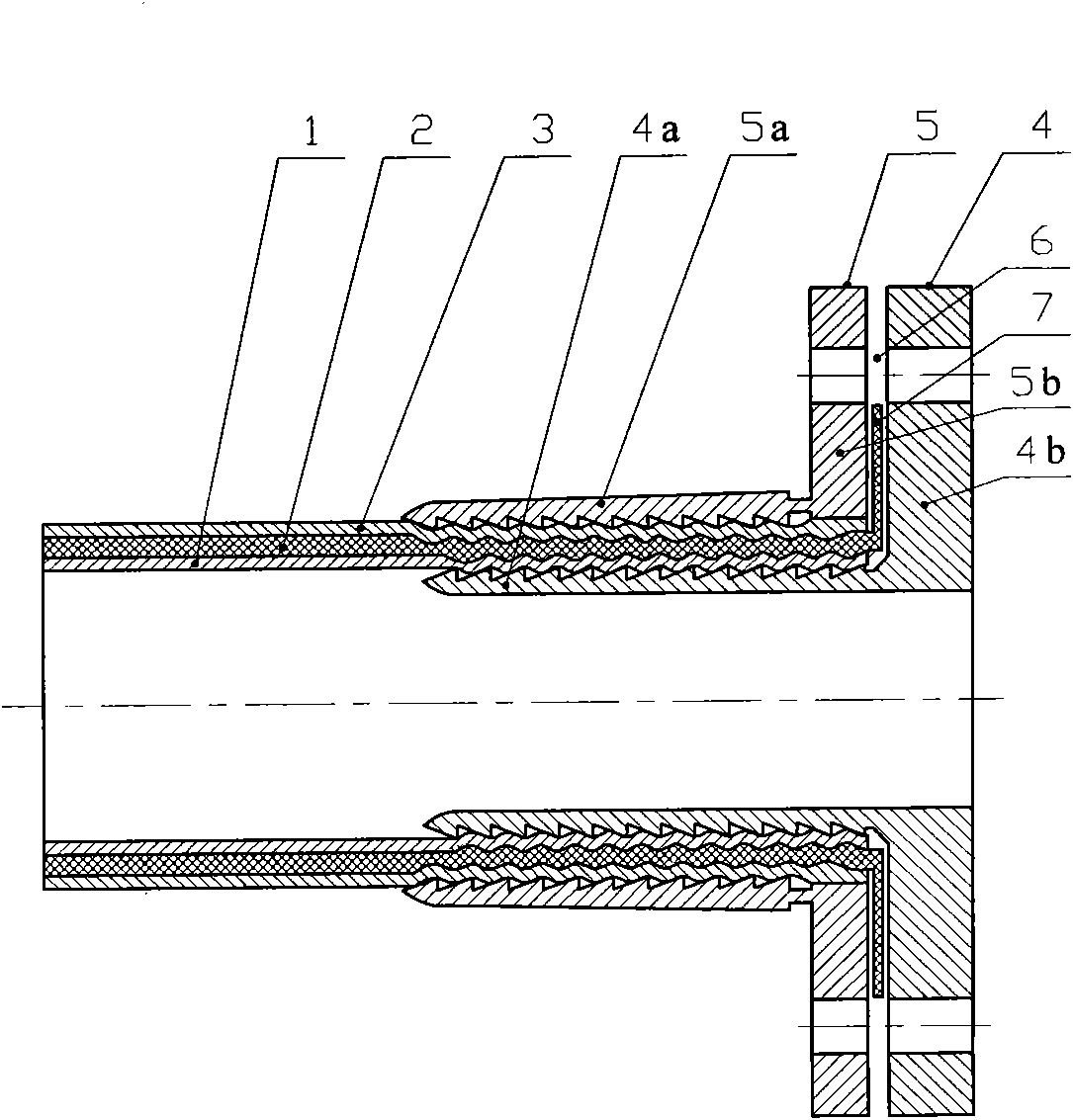

[0023] figure 1 and figure 2 Shown is an embodiment of the invention. like figure 1 As shown, the reinforced thermoplastic composite pipe in this embodiment is mainly composed of three layers, namely the inner layer 1, the middle reinforced layer 2 and the outer layer 3, and the reinforcing material of the reinforced layer 2 is steel wire rope.

[0024] like figure 1 As shown, the crimp joint includes a core tube 4 and an outer tube 5, both of which are "L" shaped and arranged parallel to each other with a gap. The horizontal section of the core tube 4 is the core 4a, the vertical section is the inner connector 4b, the horizontal section of the outer tube 5 is the buckle sleeve 5a, and the vertical section is the outer connector 5b. The inner surfaces of the core tube core 4a and the outer tube crimping sleeve 5a are both provided with unidirectional teeth, and the teeth are obliquely facing the inner connecting piece 4b / outer connecting piece 5b. The inner connecting pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com