Polymer composite materials for building air conditioning or dehumidification and preparation method thereof

A technology of air conditioning and composite materials, applied in the direction of single-component synthetic polymer rayon, air conditioning system, rayon manufacturing, etc., can solve the problem of inability to adsorb pollutant molecules, achieve the removal of fine dust such as yellow sand, and excellent moisture adsorption Sexuality, good durability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

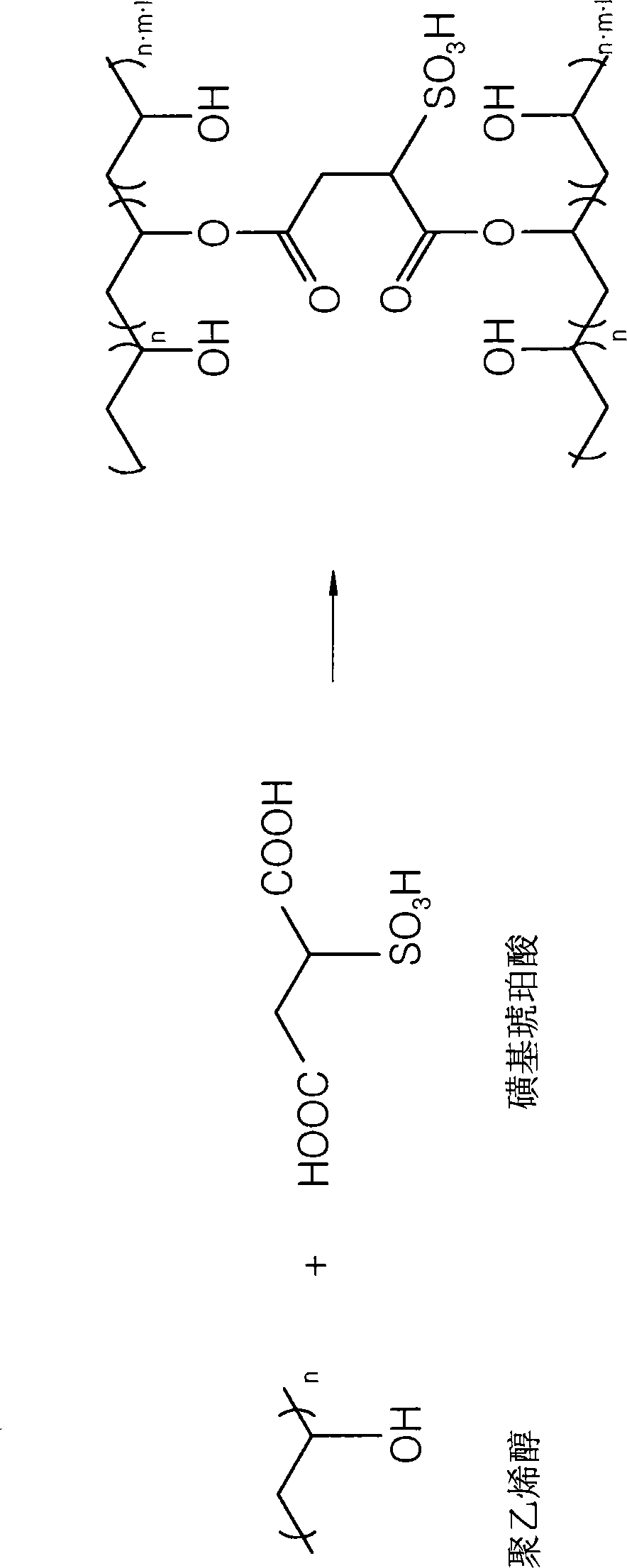

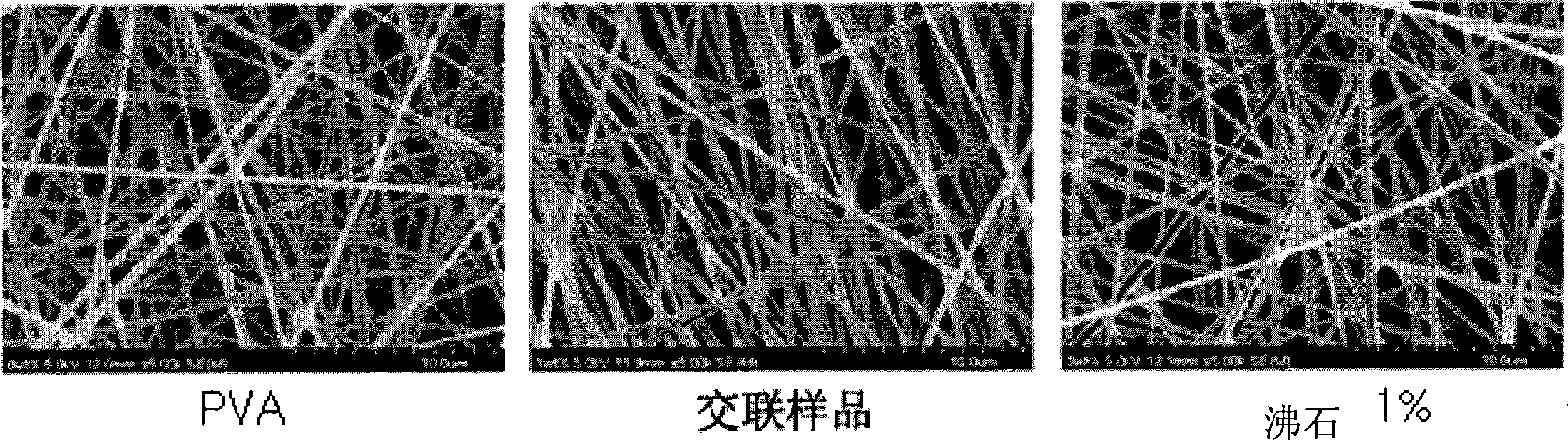

[0038] 10% by weight of polyvinyl alcohol (PVA, 87-89% hydrolyzed, Sigma-Aldrich) was dissolved in distilled water under a temperature condition of 60°C to prepare a PVA solution. To the obtained PVA solution, sulfosuccinic acid (SSA, Aldrich) as a crosslinking agent was added at 20% by weight relative to the weight of the PVA, and stirred for 1 hour or more. In addition, 1% by weight of zeolite A based on the weight of PVA was added to prepare a polymer composite material solution.

[0039] The prepared polymer composite solution was electrospun with an electrospinning device (NT-PS-35K, NTSEE Co., Korea) to fabricate a polymer nanofiber sheet. The voltage used for electrospinning was 20 kV, while the distance between the positively charged needle and the negatively charged cluster was 18 cm. The syringe for injecting the spinning solution used a 10 ml syringe made of glass, and the diameter of the needle was 0.5 mm. The supply rate of the solution was 0.7 ml per hour, and ...

Embodiment 2-4

[0043] 10% by weight of polyvinyl alcohol (PVA, 87-89% hydrolyzed, sigma-aldrich) was dissolved in distilled water under a temperature condition of 60°C to prepare a PVA solution. In addition, 10% by weight of a polystyrenesulfonic acid / maleic acid copolymer (PSSA-MA, sigma-aldrich) was produced using distilled water. The obtained 10% by weight PVA solution and 10% by weight PSSA-MA solution were mixed and stirred so that the ratios of PVA:PSSA-MA were 9:1 (Example 2), 8:2 (Example 3) and 7 : 3 (embodiment 4), to make PVA / PSSA-MA solution. To the prepared mixed solution, sulfosuccinic acid (SSA, Aldrich) as a crosslinking agent was added in an amount of 20% by weight based on the weight of PVA, and stirred for more than 1 hour to perform a crosslinking reaction.

[0044] The prepared polymer composite solution was electrospun with an electrospinning device (NT-PS-35K, NTSEE Co., Korea) to fabricate a polymer nanofiber sheet. The voltage used for electrospinning was 20 kV, wh...

Embodiment 5-7

[0048] 10% by weight of polyvinyl alcohol (PVA, 87-89% hydrolyzed, sigma-aldrich) was dissolved in distilled water under a temperature condition of 60°C to prepare a PVA solution. In addition, 10% by weight of a polystyrenesulfonic acid / maleic acid copolymer (PSSA-MA, sigma-aldrich) was produced using distilled water. The prepared 10% by weight PVA solution and 10% by weight PSSA-MA solution were mixed and stirred so that the ratio of PVA:PSSA-MA became 9:1 to prepare a PVA / PSSA-MA solution. In the prepared mixed solution, add sulfosuccinic acid (SSA, Aldrich) as a cross-linking agent in an amount of 20% by weight based on the weight of PVA and stir for more than 1 hour to carry out a cross-linking reaction, thereby obtaining a polymer solution (Example 6). Here, 1% of zeolite A was added based on the polymer weight to prepare a polymer composite material solution (Example 7).

[0049] In order to measure the antibacterial properties of the prepared polymer composite solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com