Manufacturing method of rare earth-iron ring magnet with continuous orientation controlled anisotropy

An anisotropic, ring-shaped magnet technology, applied in the manufacture of inductors/transformers/magnets, permanent magnets, permanent magnets, etc., can solve problems such as deterioration, shortage, and sacrifice of motor torque density, and achieve resource saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

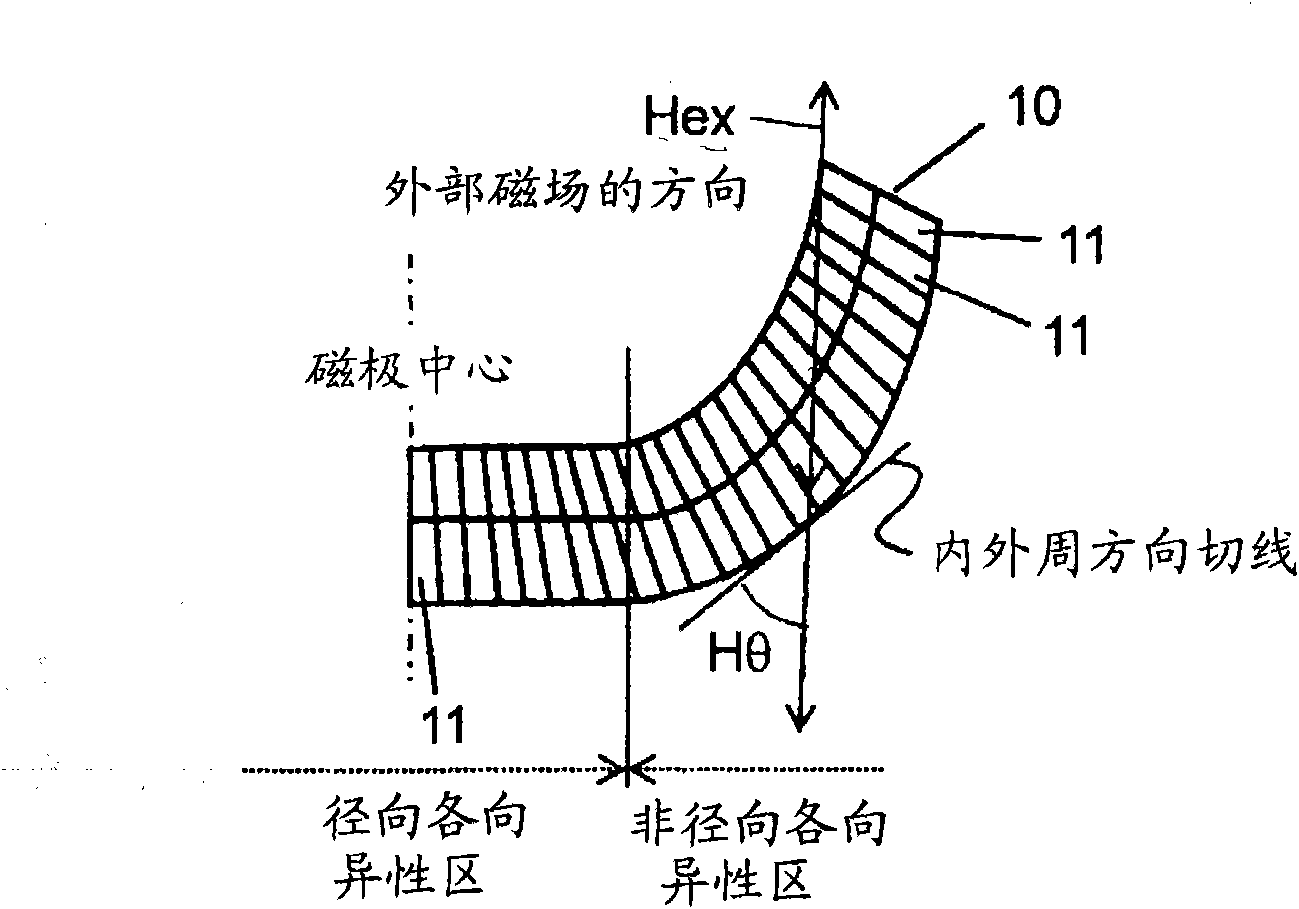

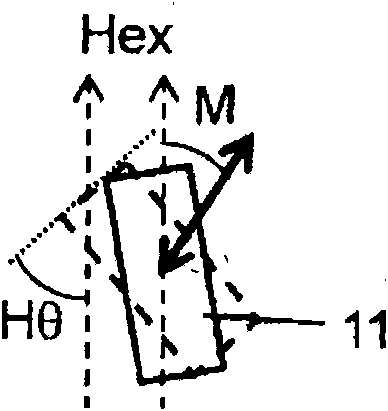

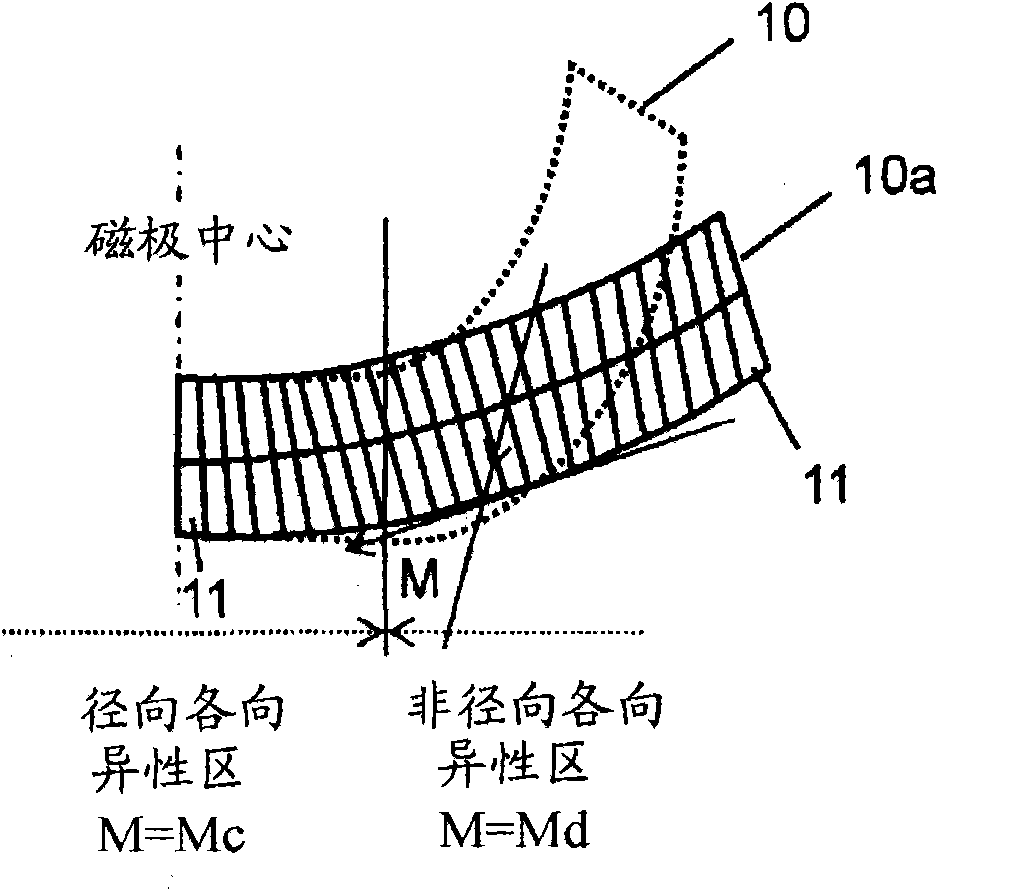

[0079] In the present invention, the following two steps must be performed. One is the step of creating a segment in which the anisotropic direction continuously changes from a direction perpendicular to the plane to in-plane using a uniform magnetic field that maintains a constant direction while mechanically designing the magnet. That is, in the produced segment, the anisotropy direction continuously changes from the direction perpendicular to the surface receiving the uniform magnetic field to the direction in which the surface receiving the uniform magnetic field extends. Another step that must be performed is to arrange a plurality of the above-mentioned segments on the circumference, extrude it into a ring shape from the thrust direction end face of one side of the segment using the rheology based on the viscous deformation of the segment, and then from the segment's Compression steps are performed on both end faces in the thrust direction.

[0080] The manufacturing st...

Embodiment

[0107] Hereinafter, the rare earth-iron ring magnet with continuously controlled anisotropy direction of the present invention will be described in more detail with reference to an embodiment of an 8-pole, 12-slot surface magnet synchronous motor (SPMSM). However, the present invention is not limited to this embodiment.

[0108] first, Figure 5 To show the density of the present invention 6.01Mg / m 3 A diagram of a scanning electron microscope (SEM) photograph of the macrostructure of a magnet. where the anisotropy Sm 2 Fe 17 N 3 Rare earth-like magnet materials and anisotropic Nd 2 Fe 14 The B-type rare earth-iron magnet material and the thermosetting resin composition are simultaneously heated at 160°C, applying an orientation magnetic field so that the uniform external magnetic field is 1.4MA / m, and performing compression molding under a pressure of 20-50MPa to form fragment. Here, the anisotropy Sm 2 Fe 17 N 3 Rare earth-like magnet material with a particle size...

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com