Processing technology of sweet osmanthus green tea

A processing technology and technology of osmanthus flower, applied in the field of processing technology of osmanthus green tea, can solve the problems of high content of tea polyphenols, lack of green tea fragrance and fragrance, bitterness and astringency of tea leaves, etc., so as to reduce the content of tea polyphenols and maintain green greenness degree, the effect of reducing bitterness and astringency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The following reference is attached Figure 2-8 The present invention will be further described in combination with specific embodiments.

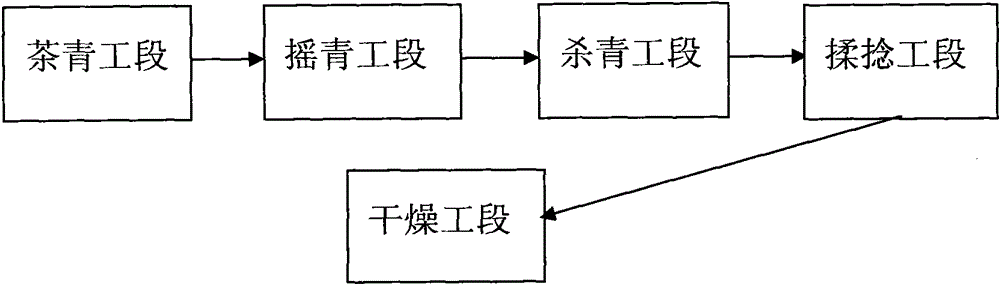

[0055] According to the processing technology of osmanthus green tea of the present invention, the processing technology of osmanthus green tea includes the following steps: the fresh leaves are subjected to the preliminary processing process, the wool tea obtained in the previous step is subjected to the finishing process, and the green tea obtained in the previous step is processed Perform scenting process.

[0056] The preliminary processing technology includes the following steps:

[0057] Tea green section, picking one bud and one leaf, one bud and two leaves, and one bud and three leaves mature tea leaves. After entering the factory, the fresh leaves will be kept at a constant temperature of 22°C for 12-14 hours in a ventilated and light-filled area. Ventilation and light transmission are required. The tea greens are evenly dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com