Production method of green tea

A production method and technology of green tea, applied in tea treatment before extraction, etc., can solve problems such as low market price, heavy grass gas, and loss of tea farmers, and achieve the effect of ensuring greenness, rich fragrance of flowers, and enhanced permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

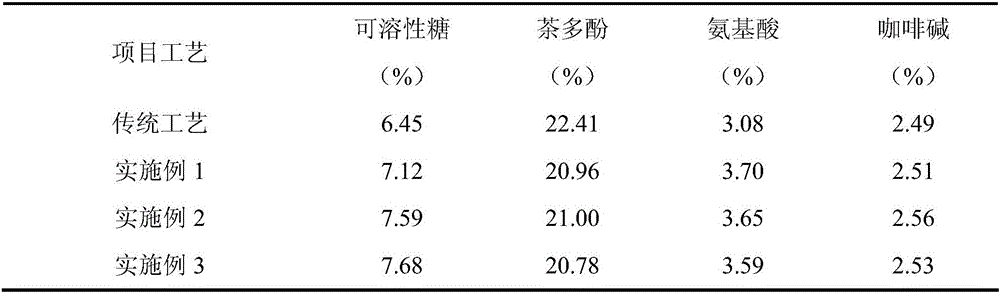

Examples

Embodiment 1

[0022] a. Greening: Put one bud and one leaf or one bud and two leaves of Lingyun Pekoe indoors for greening, and apply it at an ultrasonic frequency of 45KHz for 4 hours. The temperature of the greening is controlled at 15-20°C, and the greening time is 6- 7 hours;

[0023] b. Finishing: use steam, the temperature of the steam is controlled at 112°C to 118°C, and the finish time is 15s-25s;

[0024] c. Cold kneading: first knead at 18-22°C for 20-30 minutes, then place at 20-25°C for 3-5 hours, then knead again at 18-22°C for 20-30 minutes;

[0025] d. Drying: Dry at 40-50°C for 10-20 minutes;

[0026] e. Shaping: put the dried tea leaves in a rolling pot for shaping treatment, the cycle rolling treatment time is 30min, and the temperature is controlled at 48-52°C;

[0027] f. To enhance the aroma: enhance the aroma in a pot at a temperature of 75-85°C, and the aroma-increasing time is 20-25 minutes.

[0028] The tea product prepared in this embodiment has high-quality sty...

Embodiment 2

[0030] a. Green spreading: Put one bud and one leaf or one bud and two leaves of Lingyun Pekoe indoors for green spreading, and apply it at an ultrasonic frequency of 65KHz for 3 hours. The temperature of green spreading is controlled at 15-20°C, and the green spreading time is 6- 7 hours;

[0031] b. Finishing: use steam, the temperature of the steam is controlled at 112°C to 118°C, and the finish time is 15s-25s;

[0032] c. Cold kneading: first knead at 18-22°C for 20-30 minutes, then place at 20-25°C for 3-5 hours, then knead again at 18-22°C for 20-30 minutes;

[0033] d. Drying: Dry at 40-50°C for 10-20 minutes;

[0034] e. Shaping: put the dried tea leaves in a rolling pot for shaping treatment, the cycle rolling treatment time is 30min, and the temperature is controlled at 48-52°C;

[0035] f. To enhance the aroma: enhance the aroma in a pot at a temperature of 75-85°C, and the aroma-increasing time is 20-25 minutes.

[0036] The tea product prepared in this embodim...

Embodiment 3

[0038] a. Green spreading: Put one bud and one leaf or one bud and two leaves of Lingyun Pekoe indoors for green spreading, and apply it at an ultrasonic frequency of 55KHz for 3.5 hours. The temperature of green spreading is controlled at 15-20°C, and the green spreading time is 6- 7 hours;

[0039] b. Finishing: use steam, the temperature of the steam is controlled at 112°C to 118°C, and the finish time is 15s-25s;

[0040] c. Cold kneading: first knead at 18-22°C for 20-30 minutes, then place at 20-25°C for 3-5 hours, then knead again at 18-22°C for 20-30 minutes;

[0041] d. Drying: Dry at 40-50°C for 10-20 minutes;

[0042] e. Shaping: put the dried tea leaves in a rolling pot for shaping treatment, the cycle rolling treatment time is 30min, and the temperature is controlled at 48-52°C;

[0043] f. To enhance the aroma: enhance the aroma in a pot at a temperature of 75-85°C, and the aroma-increasing time is 20-25 minutes.

[0044] The tea product prepared in this embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com