Repair method for press roll of roll press

A repair method and technology of roller press, which can be applied to arc welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of expensive pressure rollers and increase production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

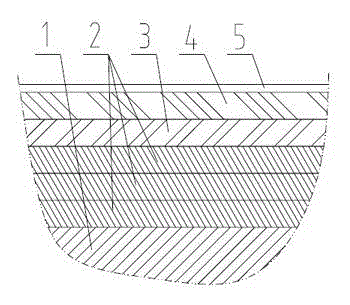

[0025] The repair method of the roller of the roller press is to pretreat the roller surface with carbon arc gas explosion on the worn surface of the roller 1 in the first line, and plan off the wear-resistant layer of the roller surface. Then use dyeing flaw detection agent to check whether there are cracks, dig holes for the cracks that appear on the surface of the roller, fill up the holes dug by manual welding, and heat the pressure roller 1 as a whole to 120-145°C . When the pressure roller 1 is heated to 120-145°C as a whole, the first layer of primer layer 2 on the roller surface is surfacing with YB-01 welding wire in open arc welding, such as figure 1 As shown, surfacing welding parameters: current 350-400A, voltage 28-32V, welding wire extension 30-35mm, welding speed 450-500mm / min, and keep the temperature of pressure roller 1 at 120-145°C. The composition of YB-01 welding wire is: 0.08%~0.14% C, 9.00%~11.00% Cr, 14.00%~17.00% Mn, 0~0.04% P, 0~0.03% S, 0~0.50% Si,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com