Wire harness workbench for assembling passenger car

A workbench and wire harness technology is applied in the field of wire harness workbenches for passenger car assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

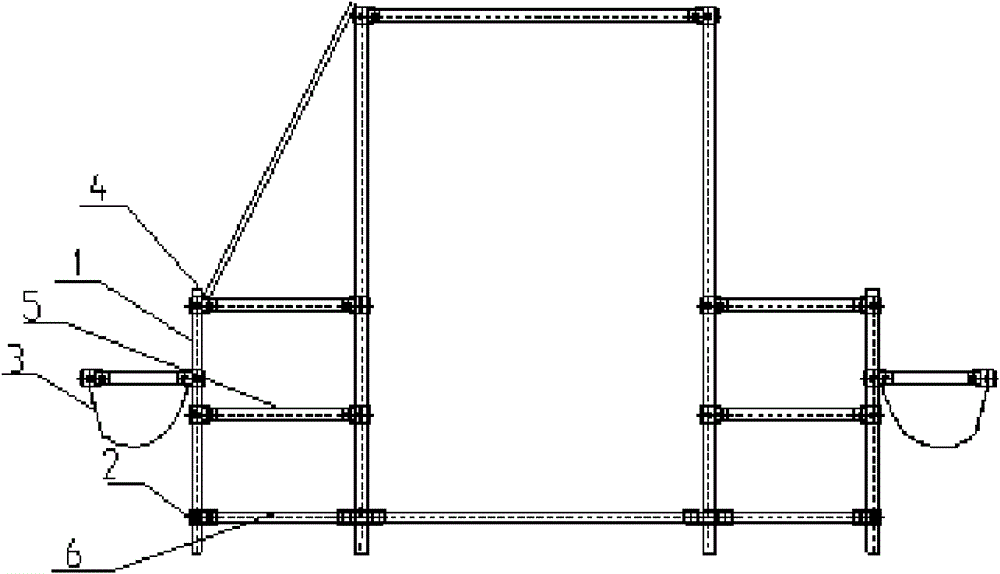

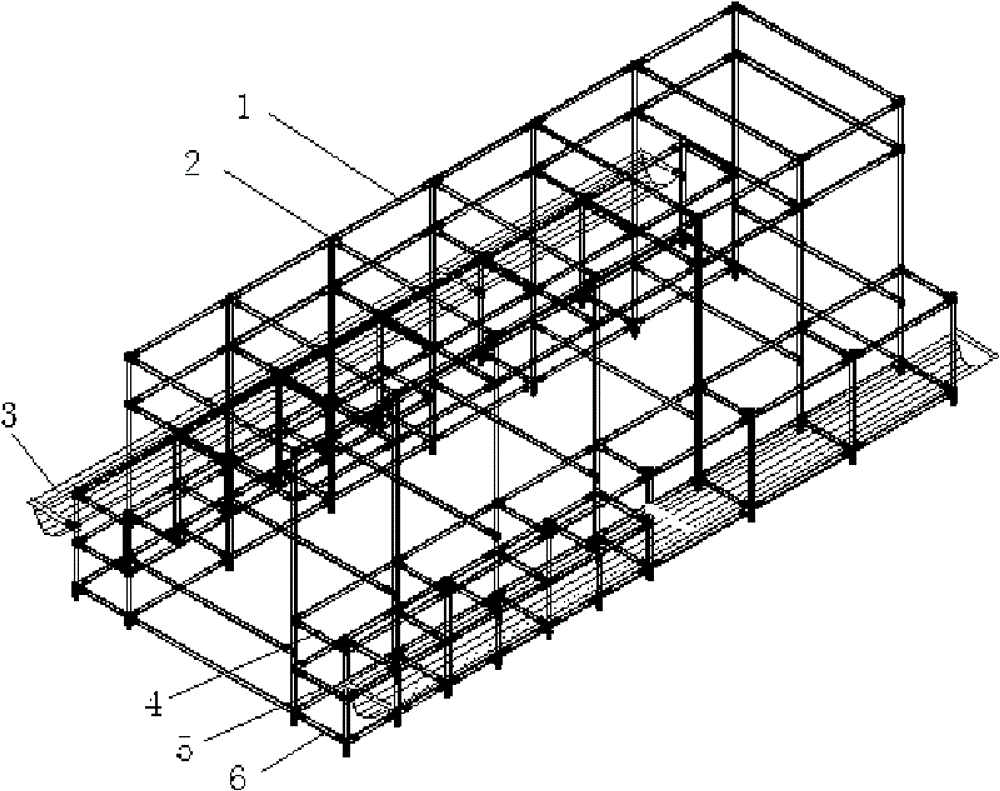

[0019] like Figure 1~2 As shown, a wiring harness workbench for passenger car assembly includes a composite pipe 1 and a joint assembly 2. The composite pipe is composed of a steel pipe and the plastic coated on the steel pipe, and the joint assembly 2 is composed of a joint, bolts and nuts. , the joints are fixedly connected with composite pipes of different lengths through bolts and nuts, and assembled into a detachable workbench.

[0020] The size and shape of the workbench can be assembled arbitrarily according to actual needs.

[0021] In this embodiment, the composite pipe 1 is assembled into a workbench comprising three layers of storage layers, namely: an upper layer 4 for placing tooling boards, a middle layer 5 for placing wires, and a lower layer 6 for placing other materials. Between the upper layer 4 and the middle layer 5 of the workbench, a cloth pocket 3 for placing auxiliary materials is fixed outwards.

[0022] Its workbench is made under the connection of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com