Radiating fin and heat exchanger

A technology of heat exchangers and heat sinks, which is applied in heat exchange equipment, lighting and heating equipment, laminated components, etc., can solve the problems of low heat dissipation efficiency of heat sinks, improve heat dissipation performance, increase heat dissipation efficiency, and facilitate processing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

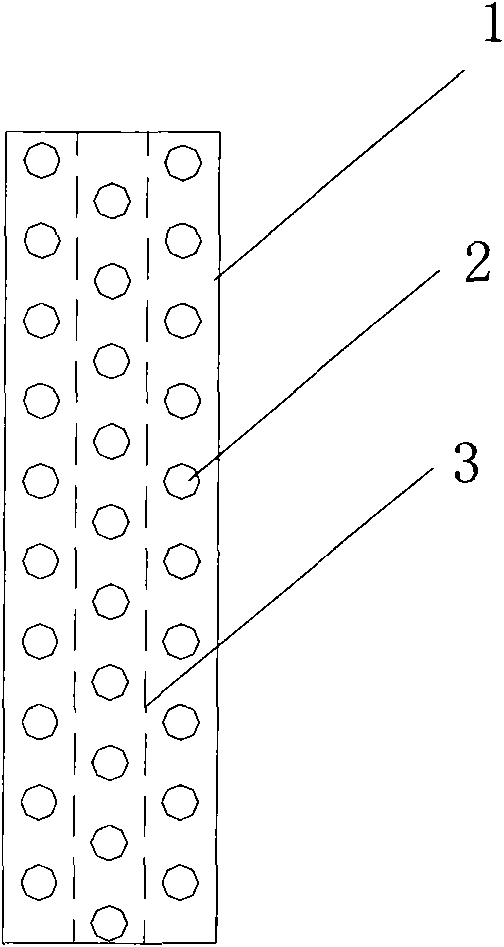

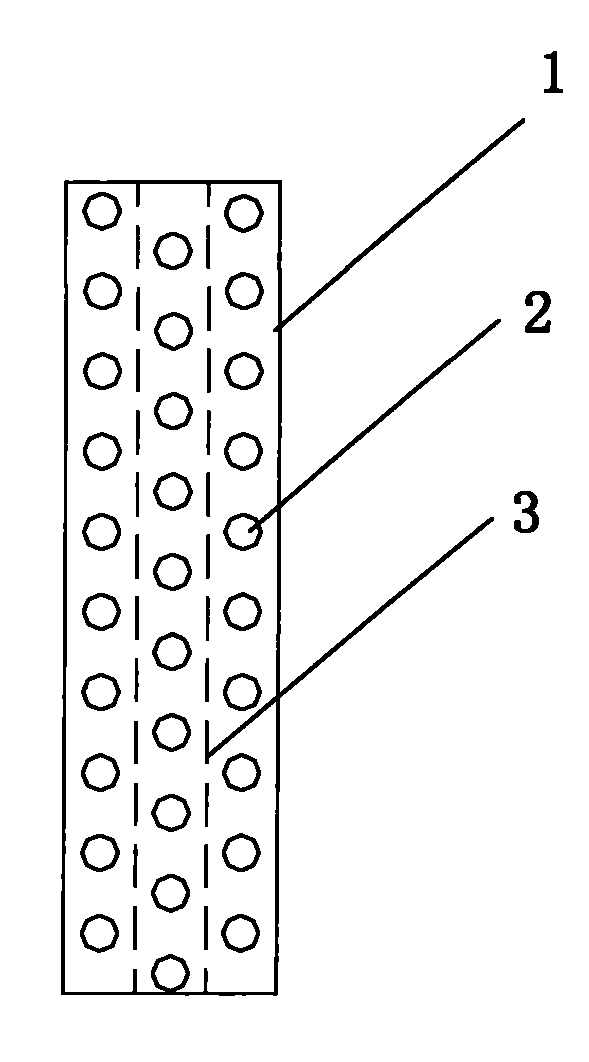

[0029] see figure 1 , an embodiment of a heat sink in the present invention, 3 rows of hairpin jacks 2 are arranged on the heat sink 1, and a penetrating heat dissipation is provided in the middle of the positions between the hairpin jacks 2 of adjacent rows of the heat sink 1. The slits 3 of the sheet form part of the connection structure. There are two slits 3, and each slit 3 is intermittently arranged along a straight line to form multiple slits, and the length of each slit is greater than the aperture of the hairpin tube jack 2.

[0030] A heat exchanger according to the present invention includes cooling fins 3 and hairpin tubes. At least two rows of hairpin tube sockets are arranged on the heat sink 3 . There is refrigerant in the hairpin tubes, and the hairpin tubes penetrate into the hairpin tube sockets. The heat sink 3 structure adopted is the heat sink 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com