Manufacture technology for integrated outer wall board for thermal insulation and decoration based on prefabricated thermal insulation core plate

A technology of external wall insulation and manufacturing technology, which is applied in the direction of manufacturing tools, ceramic molding machines, building construction, etc., and can solve problems such as troubles, tearing, loss of insulation and decoration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

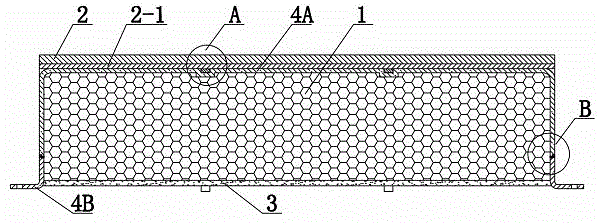

[0019] The manufacturing process of the exterior wall thermal insulation and decoration integrated board based on the prefabricated thermal insulation core board, the above process is the process step of processing on the basis of the prefabricated thermal insulation core board, the specific steps of the above process include:

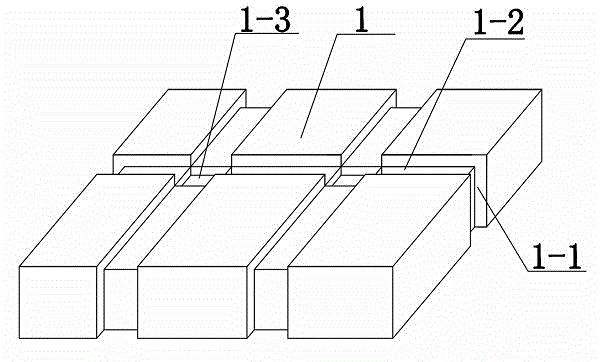

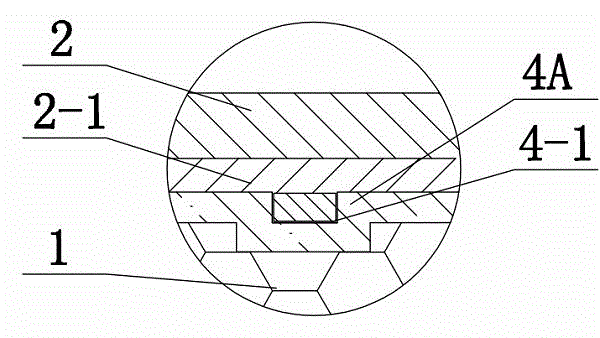

[0020] a. After cutting the thermal insulation core board 1 according to the design size, symmetrically process the vertical through groove 1-1 on the side of the thermal insulation core board 1, and process the horizontal groove connected with the vertical through groove 1-1 on the bottom surface The through groove 1-2 forms a "Xiang" type installation groove on the surface of the insulation core board 1;

[0021] b. According to the size of the "凵" type installation groove, cut out the reinforcement rib assembly, and position the reinforcement rib assembly in the "凵" type installation groove;

[0022] c. After setting the demoulding isolation layer o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com