Hot-pressing roll device for cloth tape winding machine

A hot pressing roller and winding machine technology, which is applied in the field of cloth tape winding, can solve the problems of large temperature difference at various points on the surface, uneven heating of the surface, knotting of wires, etc., achieve high-precision temperature control, convenient external power supply, and uniform temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Describe the present invention below in conjunction with specific embodiment:

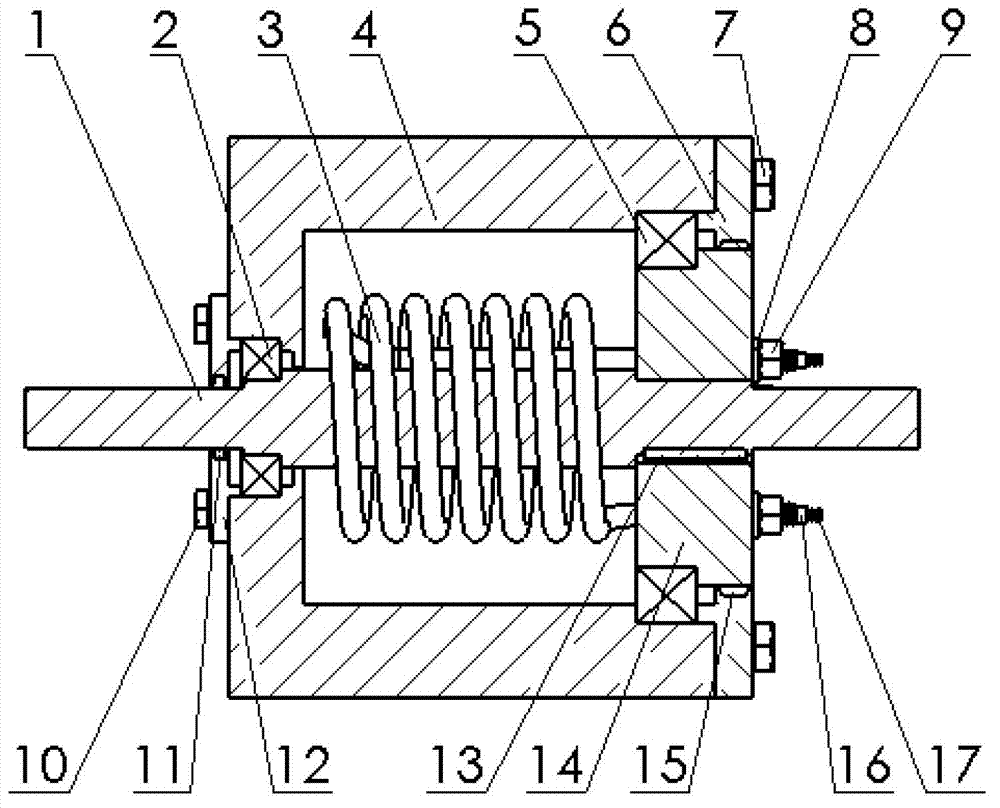

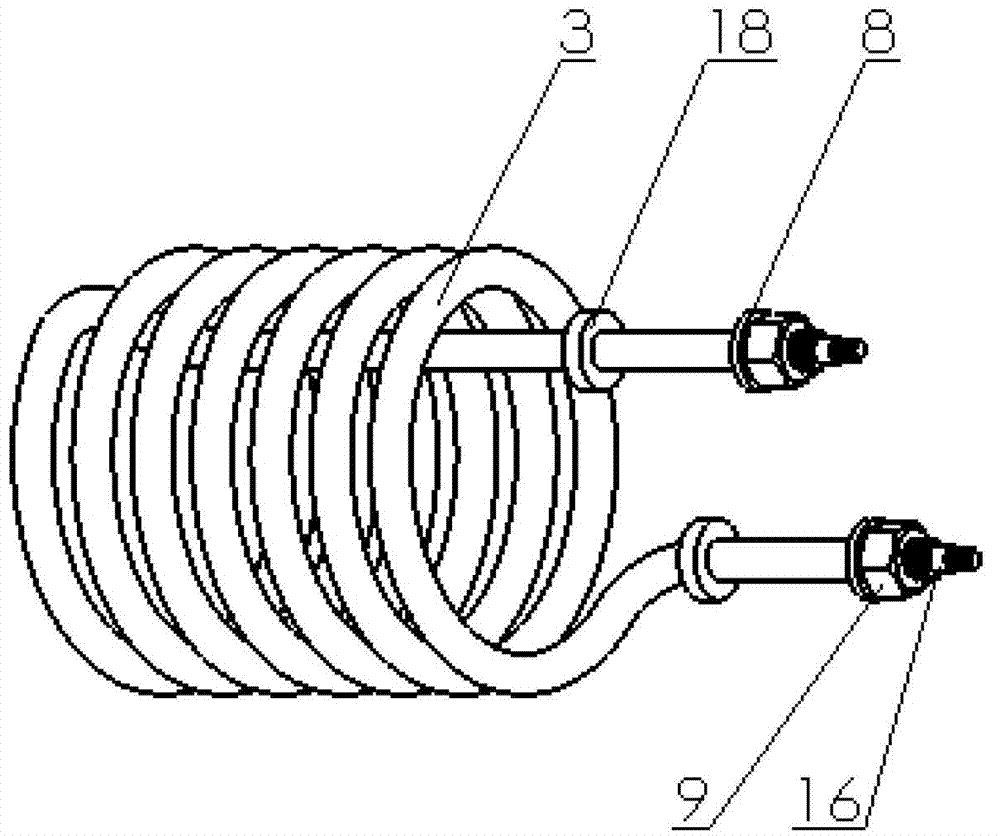

[0020] The hot pressing roller device for the tape winding machine in this embodiment includes a hot pressing roller body 4 , a central shaft 1 , an electric heating tube 3 and a bushing 14 .

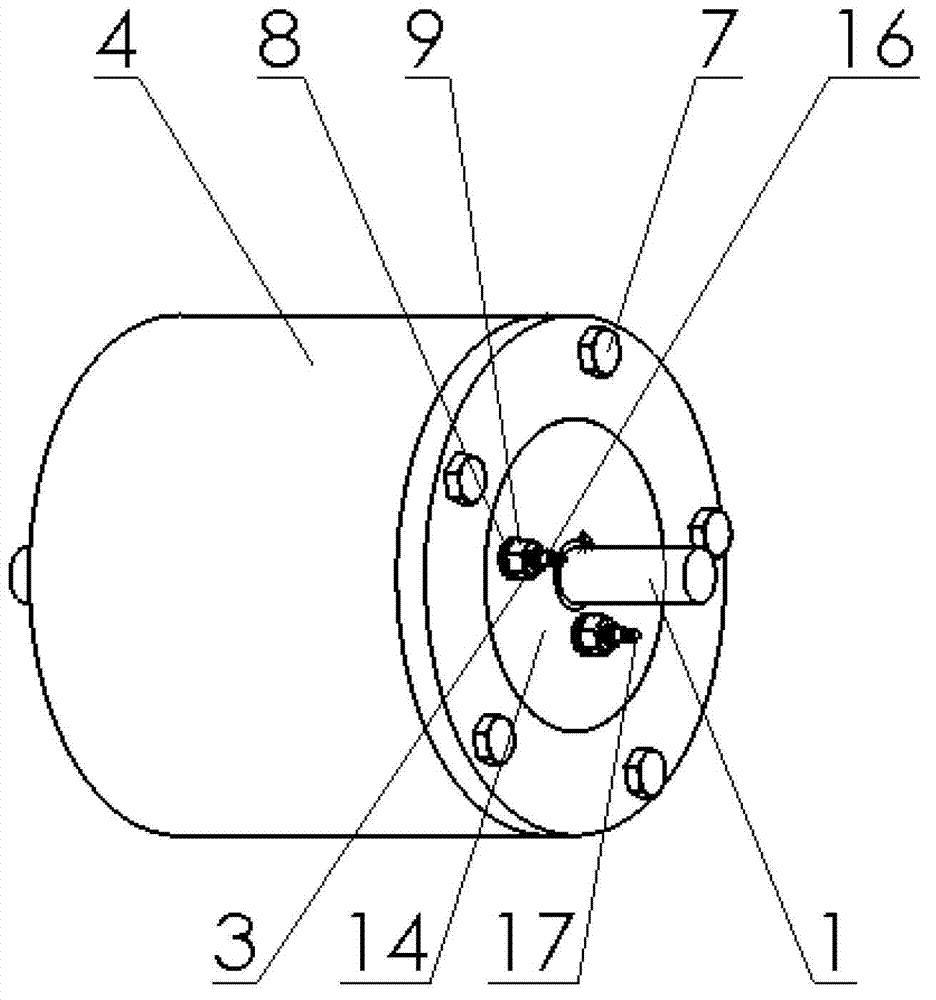

[0021] The body of the hot pressing roller is a hollow cylindrical structure with one end open, the open end of the hot pressing roller body is stepped, and the center of the other end of the hot pressing roller body has a stepped through hole.

[0022] There is a central shaft passing through the central axis of the heat press roller body. Both ends of the central shaft are stepped. There is a keyway on the second stepped shaft at one end for connecting with the bushing, and the second stepped shaft at the other end is used for For interference fit with the small end bearing 2.

[0023] The central shaft and the inner ring of the small-end bearing have an interference fit, and the outer ring of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com