Energy-saving hydraulic oil and preparation method thereof

A hydraulic oil and base oil technology, applied in the field of lubricating oil, can solve problems such as unstable performance, production and safety threats, and achieve good water separation performance, reduce wear, and reduce frictional resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

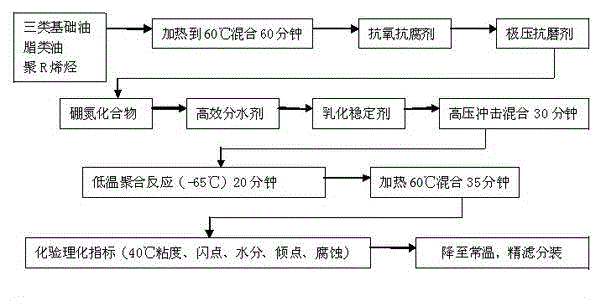

Image

Examples

Embodiment 1

[0014] Example 1: Weigh the following raw materials: base oil: three types of base oil 30, lipid oil 15, poly R olefin 20; additives: extreme pressure antiwear agent 10, antioxidant and anticorrosion agent 4, high-efficiency water separator 0.1, Emulsion stabilizer is 1, friction reducer 5.

[0015] The preparation method of energy-saving hydraulic oil comprises the following steps:

[0016] A. Add the three types of base oil, ester oil and poly R olefin into the container in sequence according to the above weight parts, heat to 50°C, and mix for 50 minutes;

[0017] B. Add anti-oxidation and anti-corrosion agent, extreme pressure anti-wear agent, high-efficiency water separator, emulsion stabilizer and friction reducer to the container in step A by weight, and carry out molecular suspension under the impact of not less than 20kg high-voltage ion beam 30 minutes, and then undergo instant ultra-low temperature polymerization at -65°C for 20 minutes; then heat it to 60°C and mi...

Embodiment 2

[0019] Example 2: Weigh the following raw materials: base oil: three types of base oil 32, lipid oil 17, poly R olefin 26; additives: extreme pressure anti-wear agent 12, anti-oxidant and anti-corrosion agent 5, high-efficiency water separator 0.3, Emulsion stabilizer is 1.5, friction reducer 6.

[0020] A. Put the three types of base oil, ester oil, and poly R olefin into the container in sequence according to the above weight parts, heat to 55°C, and mix for 60 minutes;

[0021] B. Add anti-oxidation and anti-corrosion agent, extreme pressure anti-wear agent, high-efficiency water separator, emulsion stabilizer and friction reducer to the container in step A by weight, and carry out molecular suspension under the impact of not less than 20kg high-voltage ion beam 30 minutes, and then undergo instant ultra-low temperature polymerization at -65°C for 20 minutes; then heat it to 60°C and mix for 35 minutes;

[0022] C, the product obtained in step B is down to normal temperatu...

Embodiment 3

[0023] Embodiment 3: Weigh the following raw materials: base oil: three types of base oil 40, lipid oil 20, poly R olefin 30; additives: extreme pressure antiwear agent 15, antioxidant and anticorrosion agent 6, high-efficiency water separator 0.5, Emulsion stabilizer is 3, friction reducer 8.

[0024] A. Put the three types of base oil, ester oil, and poly R olefin into the container in sequence according to the above weight parts, heat to 60°C, and mix for 70 minutes;

[0025] B. Add anti-oxidation and anti-corrosion agent, extreme pressure anti-wear agent, high-efficiency water separator, emulsion stabilizer and friction reducer to the container in step A by weight, and carry out molecular suspension under the impact of not less than 20kg high-voltage ion beam 30 minutes, and then undergo instant ultra-low temperature polymerization at -65°C for 20 minutes; then heat it to 60°C and mix for 40 minutes;

[0026] C, the product obtained in step B is down to normal temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com