Weft insertion device of circular loom

A technology of weft insertion device and circular loom, applied in the field of machinery, can solve problems such as inability to weave, and achieve the effect of eliminating the phenomenon of strong extrusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

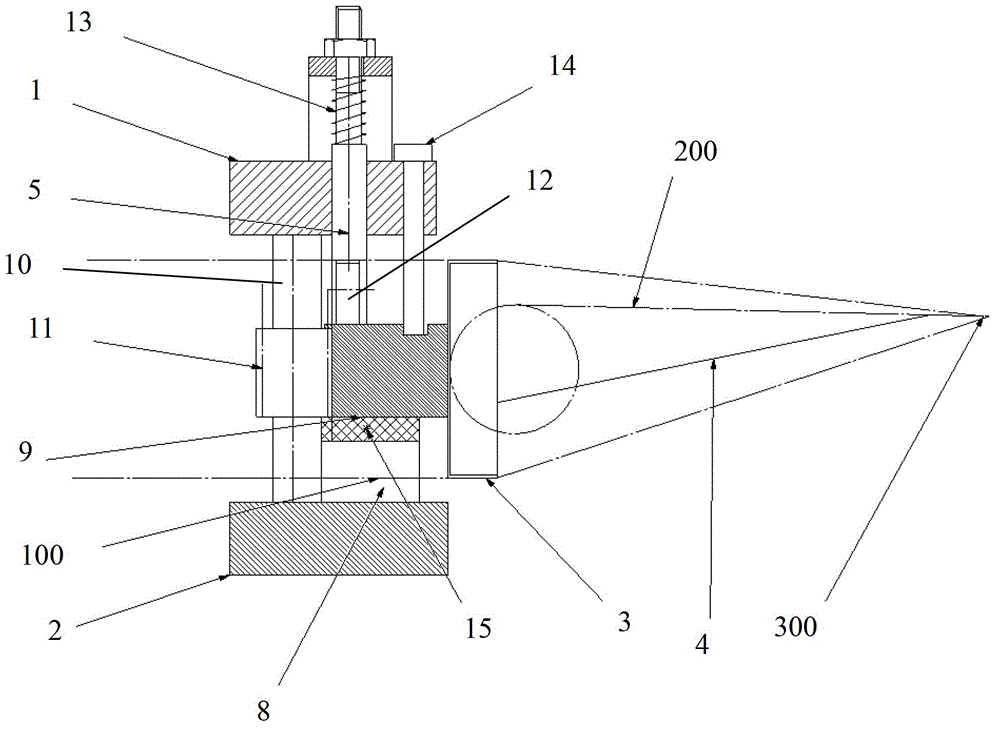

[0010] like figure 1 As shown, a weft insertion device of a circular loom according to the present invention includes an upper ring 1, a lower ring 2, a bobbin case 3 and a warp dividing sheet 8, wherein the upper ring 1 and the lower ring 2 are up and down Arranged in parallel, the bobbin case 3 is arranged between the upper ring 1 and the lower ring 2, and the warp dividing sheet 8 is arranged between the upper ring 1 and the lower ring 2 and supports the upper ring 1 and the lower ring 2, the shuttle The back of the shell 3 is provided with a rack 9, a gear shaft 10 is provided between the upper ring 1 and the lower ring 2, and the gear shaft 10 is provided with a gear 11, and the gear 11 meshes with the rack 9 , include a boss plane in the divided warp sheet 8, a nylon strip 15 is arranged between the bottom surface of the rack 9 and the boss plane, the boss plane is parallel to the plane of the upper ring 1 and the lower ring 2, the bottom surface of the nylon strip 15 A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com