Reciprocating eccentricity prevention oil sealing device, and application method and application thereof

An eccentric and sealing sleeve technology, which is applied to the sealing of the engine, engine components, mechanical equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

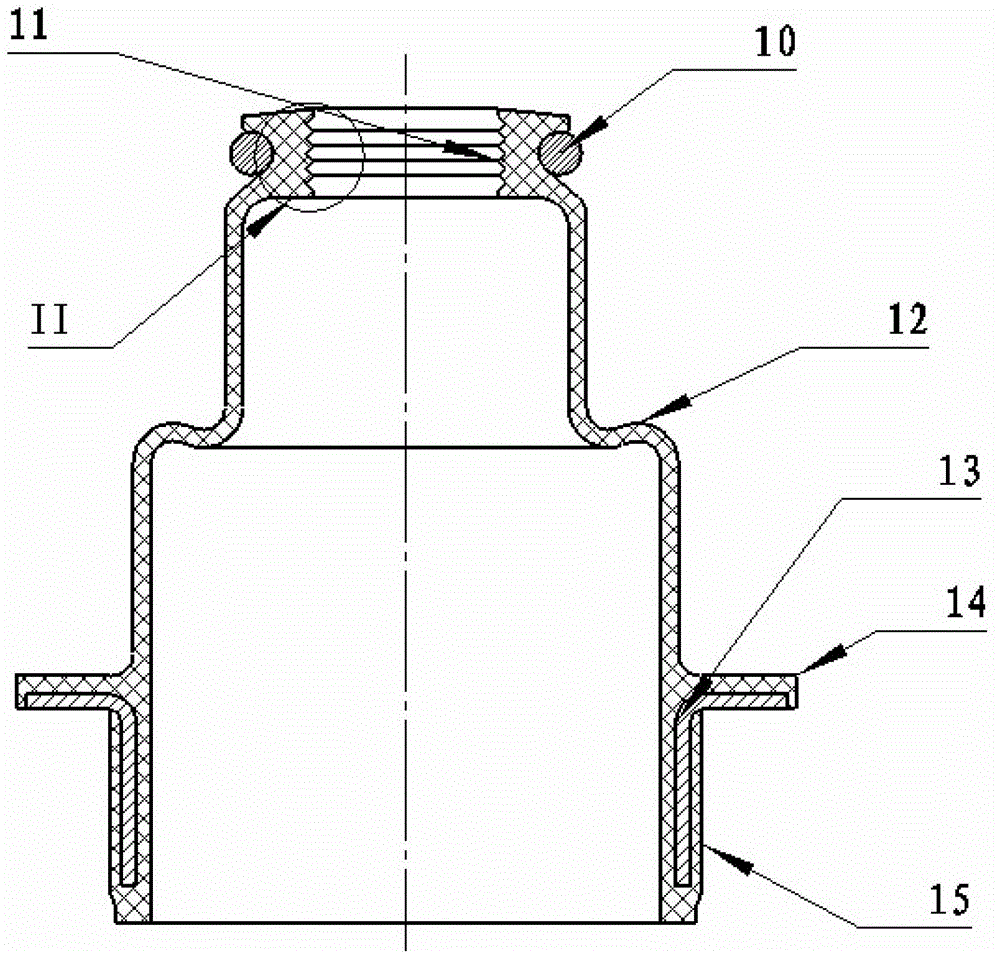

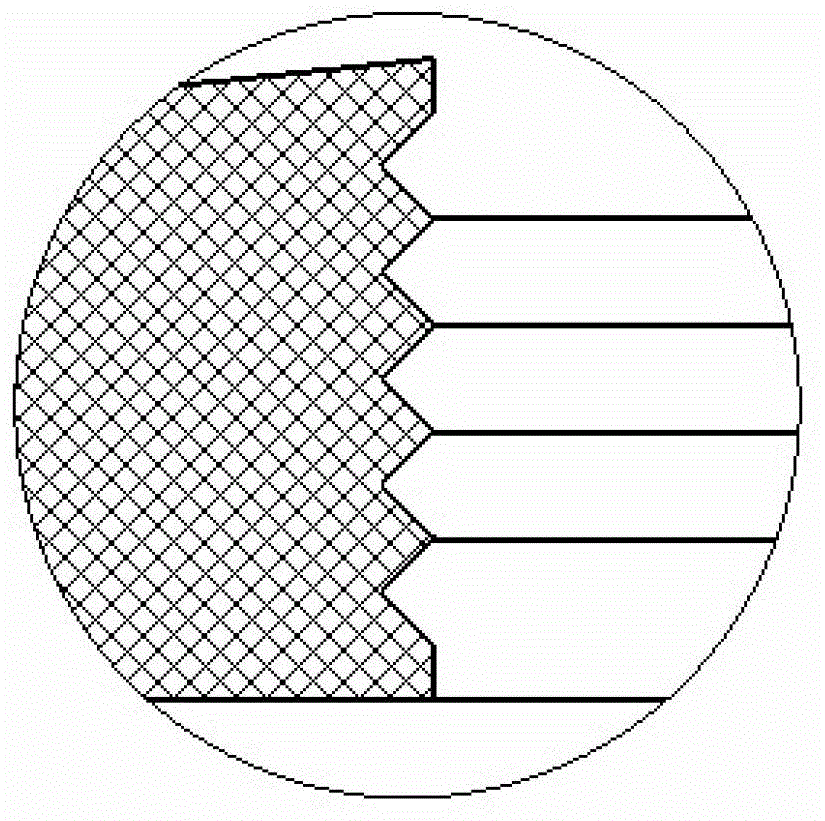

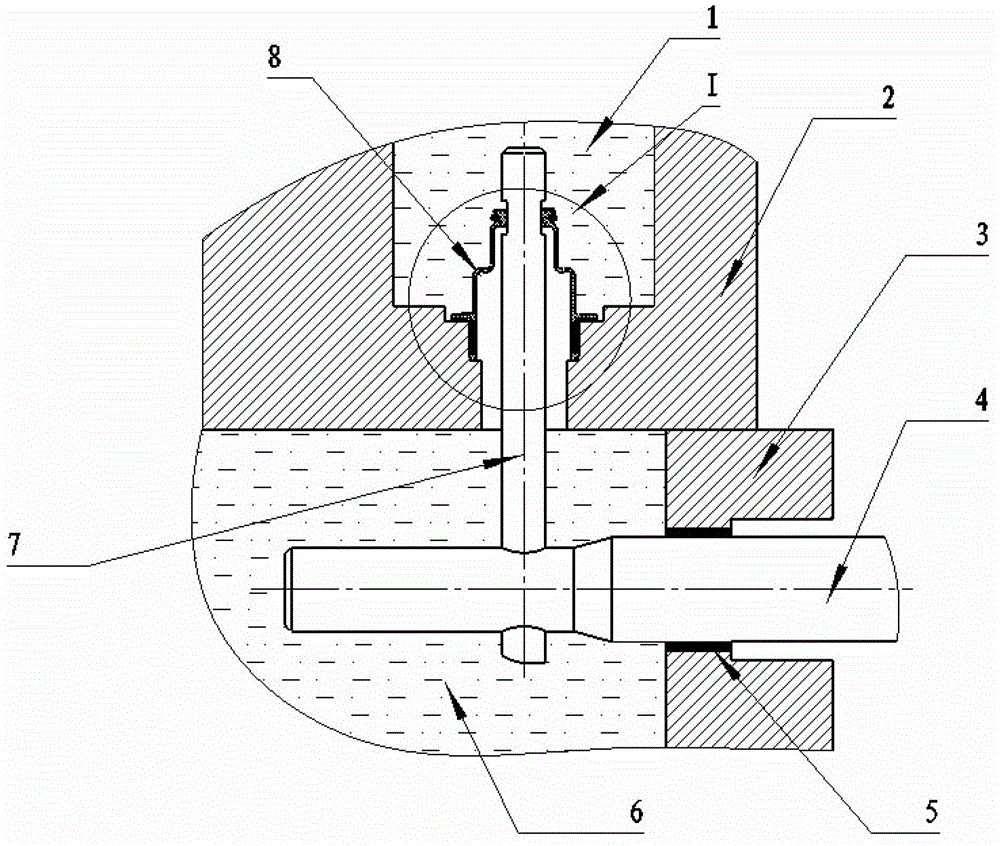

[0024] Such as Figure 1 to Figure 4 As shown, a reciprocating eccentricity-resistant oil sealing device includes a long-tube stepped sealing sleeve 8, and the sealing sleeve 8 is provided with a rounded groove 12 at the step distribution position; the wall of the sealing sleeve 8 The thickness is 1.5 mm; the sealing sleeve 8 is provided with a sealing lip 11; the bottom of the sealing sleeve 8 is provided with a rigid skeleton 13 in a flanging structure 14, and a sealing rubber body 15 is provided on the outside of the skeleton 13; The sealing lip 11 is set to be wave-shaped; the sealing lip 11 is set to form an interference fit structure with the connecting rod 7; the sealing rubber body 15 outside the skeleton 13 is set to form an interference fit with the casting hole structure.

[0025] The method of using the oil sealing device for complex resistance to eccentricity includes the following steps:

[0026] The first step is to install the shaft 4 into the casting 3, and ...

Embodiment 2

[0032] The same as in the first embodiment, the difference is that the wall thickness of the sealing sleeve is 1 mm, and the sealing lip 11 is set in a zigzag shape.

Embodiment 3

[0034] Same as embodiment 1, the difference is that the wall thickness of the sealing sleeve is 2mm.

[0035] In this way, when working, a reciprocating eccentricity-resistant oil sealing device of the present invention and its use method and application, the casting 2 forms an oil chamber 1, and the oil chamber is filled with gear oil, and the casting 3 forms an oil chamber 6, and there are gears in the oil chamber. Oil, the connecting rod 7 is connected with the shaft 4, and the shaft 4 drives the connecting rod 7 to reciprocate up and down, and there is a 10° swing. There is a large gap between the connecting rod 7 and the hole of the casting 2, and the sealing sleeve 8 needs to be used here for sealing , so as to prevent the oil in the two oil chambers from permeating each other; the gap between the shaft 4 and the casting 2 is sealed by the oil seal 5. When assembling, put the shaft 4 into the casting 3, and then install the sealing sleeve 8 in the seat hole of the casting...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com