A power heat pipe system

A power heat pipe and air duct technology, which is applied in the field of heat exchange, can solve the problems of insufficient circulating power and incomplete gas-liquid separation, so as to reduce the limitation of use conditions, solve the problems of high and low position difference and conveying distance, and improve the heat exchange efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 2

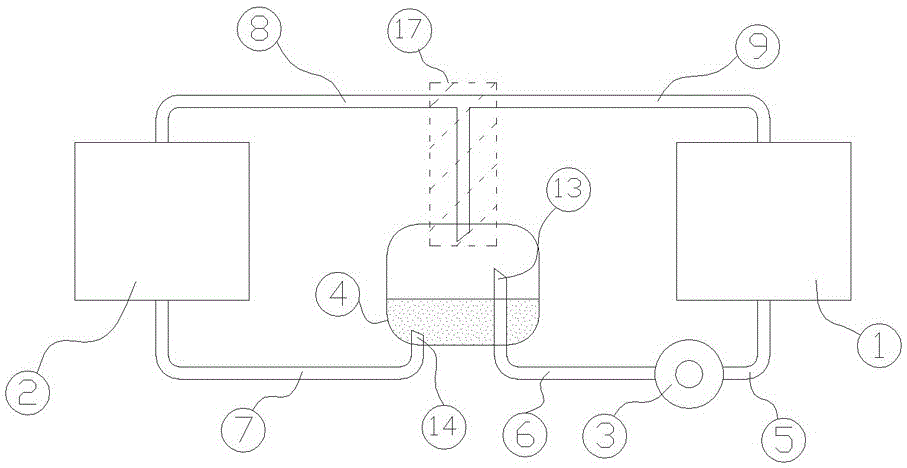

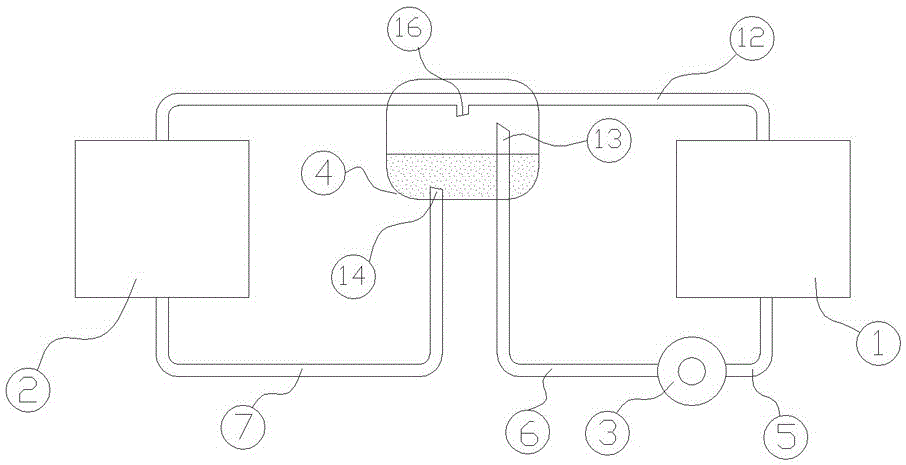

[0028] image 3 exist figure 2 On the basis of the power heat pipe device shown, the return air device (17) is a row of return air holes (16), and the positions of the return air holes (16) are arranged on the two-phase flow pipe (12) according to the flow direction of the working medium in the pipe. , and this device requires that the part of the pipe with return holes distributed on the two-phase flow pipe (12) is in the liquid storage tank (4), its position is above the liquid surface in the liquid storage tank (4), and in the liquid storage tank (4) The gaseous intermediate medium separated from the gas-liquid in the medium flows back to the two-phase flow pipe (12) through the air return hole (16) and finally enters the condenser (1) for the next cycle. Other components are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com