Kitchen garbage pre-treating process of kitchen garbage pre-treating cart

A food waste and pretreatment technology, applied in trolleys, multi-axis trolleys, motor vehicles, etc., can solve the problem of low recycling rate, inability to remove hard objects such as metal and glass at the same time, and incomplete solid-liquid separation of food waste, etc. problems, to achieve the effect of low cost, shortened processing cycle and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Preferred embodiments of the present invention are described in detail below.

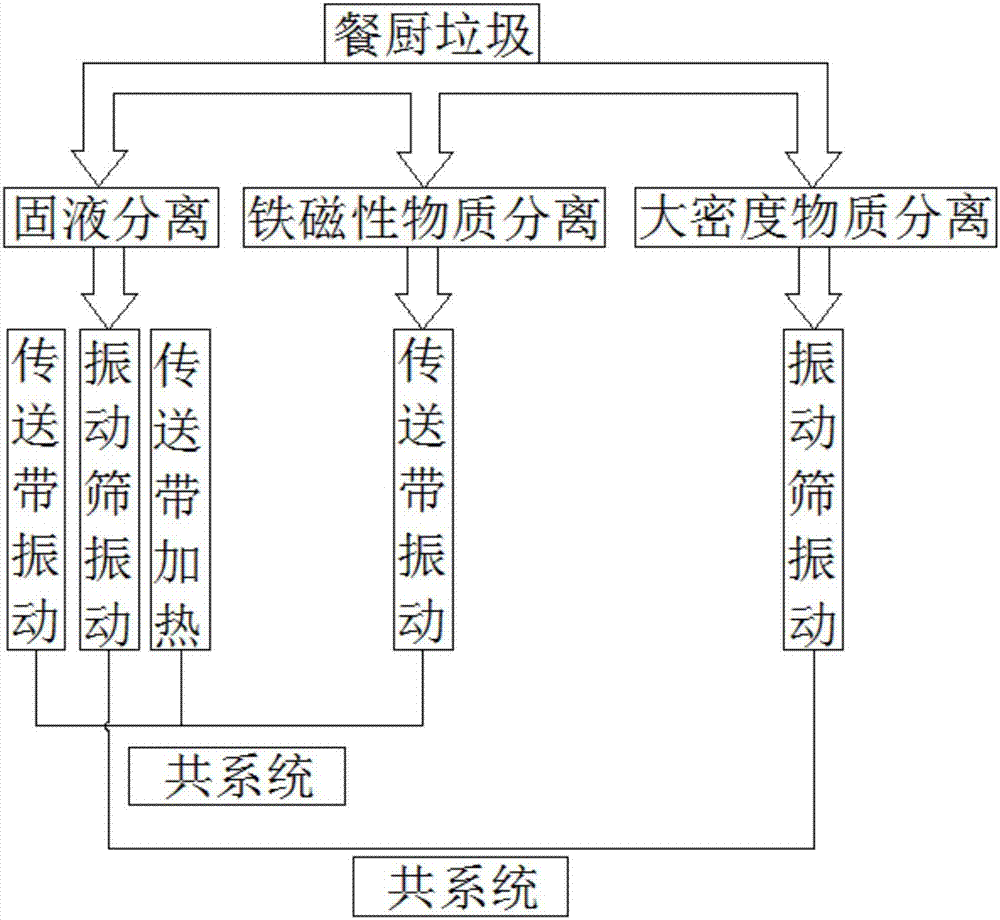

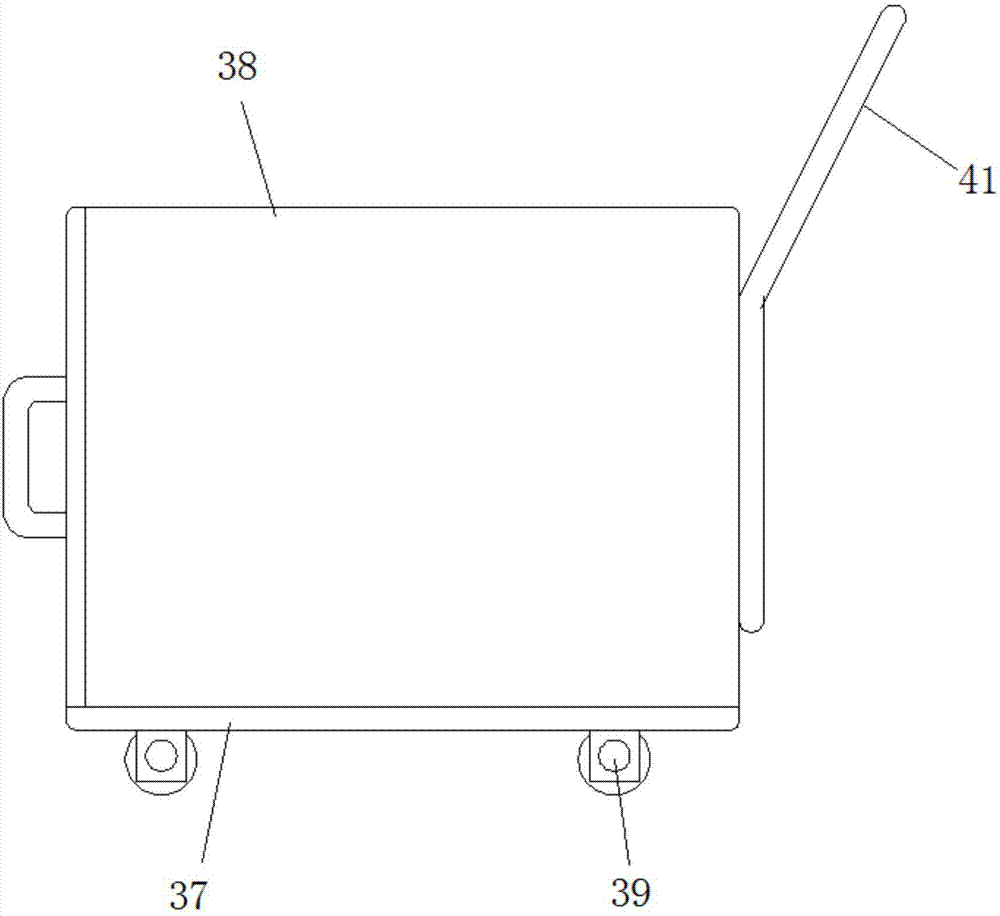

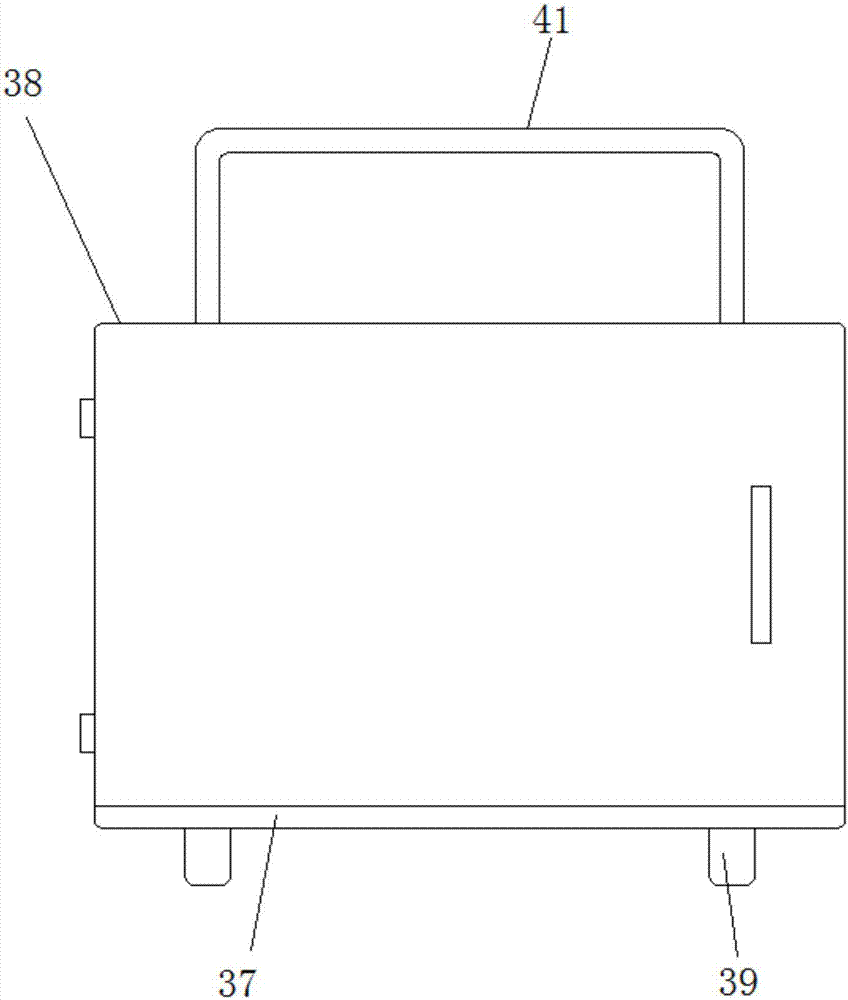

[0046] Such as Figure 1-Figure 11As shown, the food waste pretreatment process of a food waste pretreatment trolley in this embodiment, the food waste pretreatment trolley includes a car body 37, a shell 38 fixed on the car body, and a car body fixed in the shell. Feeding hopper 1, receiving hopper 2, solid-liquid separation and ferromagnetic material separation composite system 3 and large-density material separation system 4, the car body has a roller mechanism 39, which can reduce the movement resistance, and the outer shell is a thin shell box body. One side is provided with a manual door 40, the shell can be opened to facilitate the removal of separated garbage. At the same time, a door handle is provided on the manual door to facilitate switch operation, and a cart handle 41 is provided on the other side corresponding to the manual door. The cart can be used to move the driving and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com