Method for separating lead and antimony from jamesonite

A technology of brittle sulfur-lead-antimony ore and sodium thioantimonate, applied in the direction of improving process efficiency, etc., can solve the problem of incomplete separation of lead and antimony, and achieve a good effect of separation of lead and antimony

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

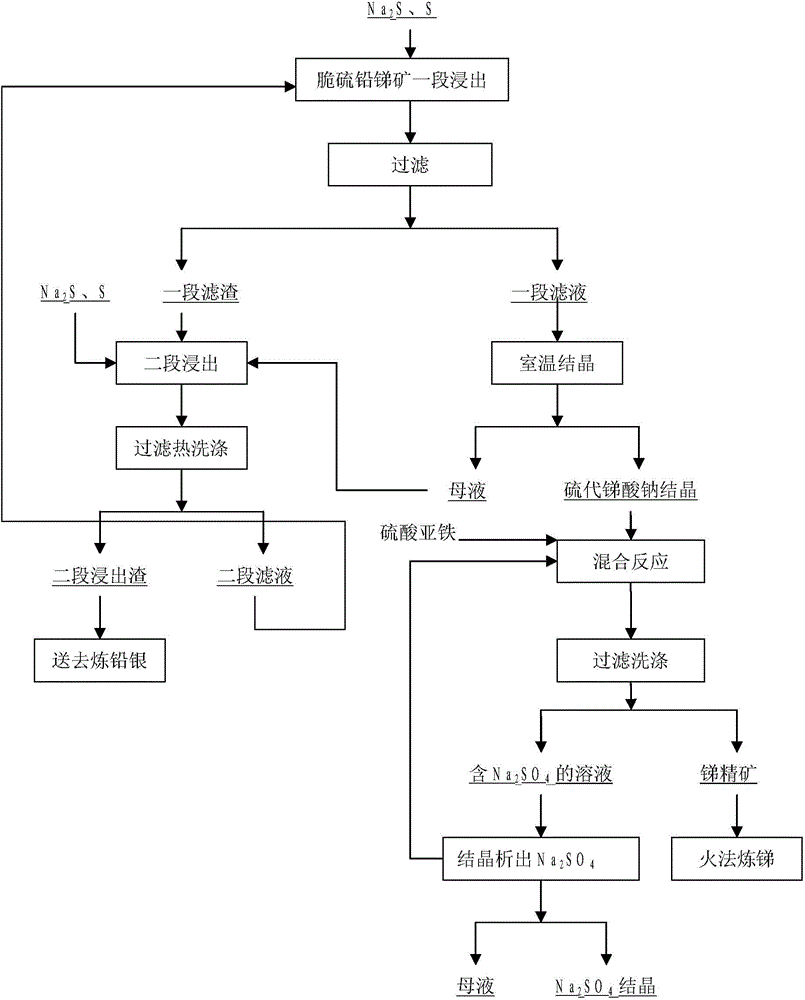

Image

Examples

Embodiment 1

[0044] The method for the separation of lead and antimony in the brittle pyroprobite of the present invention comprises the following steps:

[0045] Raw material composition and content:

[0046] The brittle sulfur-lead-antimony concentrate contains Sb24.17%, Pb26.75%, Ag850g / t, Fe11.31%, S23.08%, Zn6.68%, moisture 1.85%.

[0047] First, the brittle sulfur-lead-antimony concentrate is ground into a fine powder of 100-200 mesh, 70% of which reaches 200 mesh. Then use Na 2 S Two-stage leaching, adding sulfur as an additive during the leaching process, the specific control technical conditions are:

[0048] One-stage leaching: 1000 grams of brittle sulfur-lead-antimony concentrate, liquid-solid ratio 3:1, Na 2 S concentration of 90g / l, sulfur 50g, NaOH 30g / l, stirring, reacting at a temperature of 95-105°C for 1 hour, filtering to obtain a section of leach residue and filtrate, the filtrate was naturally cooled, and sodium thioantimonate crystallized and precipitated.

[004...

Embodiment 2

[0054] Another example of the method for the separation of lead and antimony in the brittle pyrostibite of the present invention comprises the steps:

[0055] Raw material composition and content:

[0056] Composition of brittle pyrobenite: Sb22.92%, Pb25.70%, Ag803.59g / t, Fe14.46%, S24.86%, moisture 2.02%.

[0057] Firstly, the brittle sulfur-lead-antimony ore is ground into a fine powder of 100-200 mesh, 70% of which reaches 200 mesh. Then use Na 2 S Two-stage leaching, adding sulfur as an additive during the leaching process, the specific control technical conditions are:

[0058] One-stage leaching: 1000 grams of brittle sulfur-lead-antimony concentrate, the liquid-solid ratio is 4:1, the NaOH content in the solution is 70g / l, NaOH 2 The S content is 70g / l, sulfur is 60g, stirred, reacted at a temperature of 95-105°C for 1 hour, filtered to obtain a section of leach residue and filtrate, the filtrate is naturally cooled, and sodium thioantimonate crystallizes out.

[0...

example

[0064] The third example of the method for the separation of lead and antimony in the brittle pyrostibite of the present invention comprises the steps:

[0065] Raw material composition and content:

[0066] The brittle sulfur-lead-antimony concentrate contains Sb24.17%, Pb26.75%, Ag850g / t, Fe11.31%, S23.08%, Zn6.68%, moisture 1.85%.

[0067] First, the brittle sulfur-lead-antimony concentrate is ground into a fine powder of 100-200 mesh, 70% of which reaches 200 mesh. Then use Na 2 S Two-stage leaching, adding sulfur as an additive during the leaching process, the specific control technical conditions are:

[0068] One-stage leaching: brittle sulfur-lead-antimony concentrate 1000g, liquid-solid ratio 3:1, sulfur 36g, add 3000ml circulating mother liquor of a certain leaching, Na in the mother liquor 2 S content 27.27g / l, NaOH 60.9g / l, add Na 2 S to 80g / l, stirred, reacted at 95-105°C for 1 hour, filtered to obtain a section of leach residue and filtrate, the filtrate was ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com