A separation cylinder for a thin lead grid separator for processing waste lead-acid batteries

A waste lead-acid battery and separation cylinder technology, which is applied in the field of separators, can solve the problems of incomplete separation of fine lead grid lead needles and lead mud, and achieve the effects of low labor intensity, less ash residue, and high lead output rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

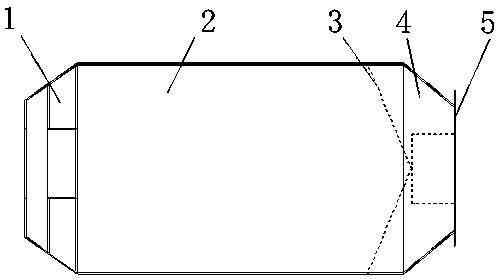

[0025] Embodiment 1: The separation cylinder includes: feed throat 1, cylinder body 2, material stop orifice plate 3, discharge port 4, water stop ring 5 and drum liner 6; the main body of the cylinder body 2 is a circular tube with two ends It is a round platform tube, and the diameter of the external port is smaller than the diameter of the main round tube. The feed throat 1 is connected to the feed port in the cylinder 2, and the feed stop orifice 3 and the discharge port are connected to the discharge port in the cylinder 2. The port 4 is connected with a water stop ring 5 at the end of the discharge port of the cylinder body 2 , and a drum liner 6 is connected with the main body of the cylinder body 2 .

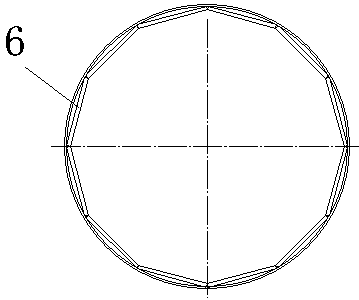

[0026] The drum liner 6 has multiple pieces, which are rectangular, and the rectangular drum liner 6 is connected end to end, and is uniformly distributed in a polygonal shape in the cylinder body 2 .

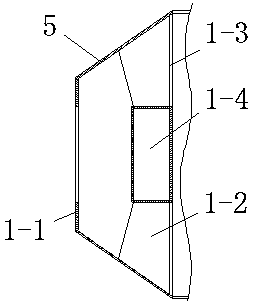

[0027] The feed throat 1 includes: an anti-spill flange 1-1, a mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com