Compound vacuum gauge calibration system and method

A calibration method and composite technology, applied in the field of measurement, can solve the problems of high production cost and large vacuum gauge calibration system, and achieve the effect of low cost, small weight and volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

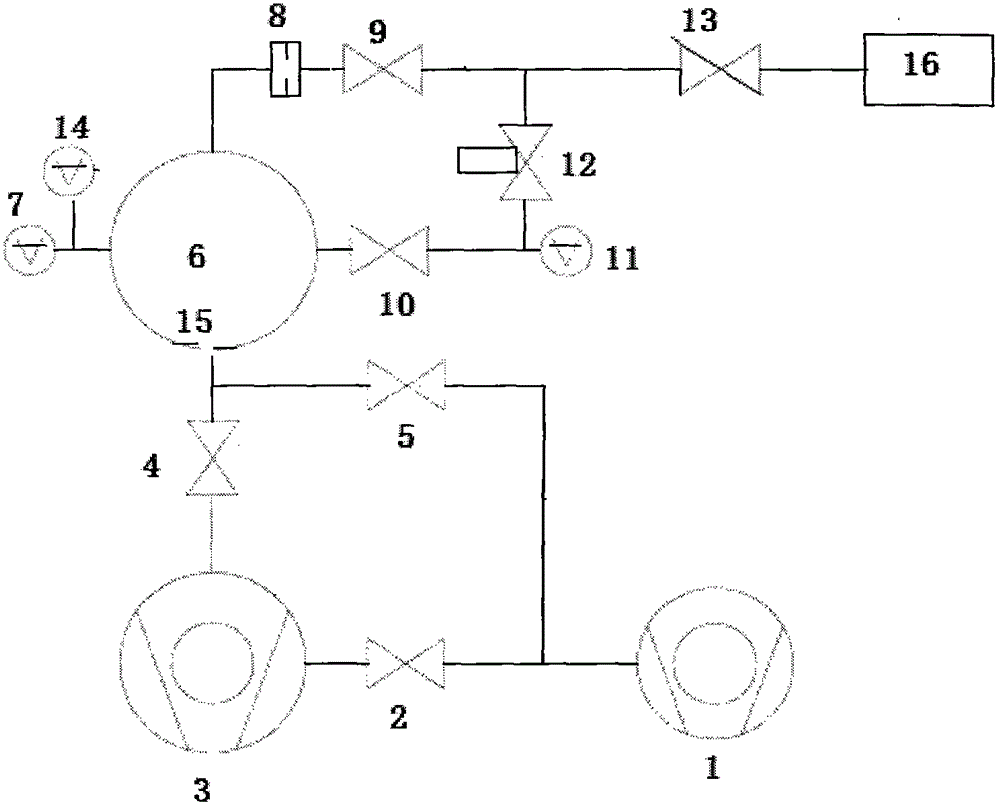

[0029] Such as figure 1 As shown, the compound vacuum gauge calibration system and method described in this embodiment includes: the system includes: a mechanical pump 1, a molecular pump 3, a first vacuum valve 2, a second vacuum valve 4, and a third vacuum valve 5. The fourth vacuum valve 9, the fifth vacuum valve 10, the sixth vacuum valve 12, the seventh vacuum valve 13, the vacuum gauge 7, the capacitance film gauge 11, the third vacuum gauge 14, the calibration chamber 6, the first vacuum valve with a diameter of 2um A small hole 8, a second small hole 15 with a diameter of 11mm, and an air source 16, wherein the valve 12 is a three-way valve with a 1mL sampling chamber.

[0030] The connection relationship is as follows: the mechanical pump 1 is connected to the first vacuum valve 2 at the same time; the other end of the first vacuum valve 2 is connected to the molecular pump 3; one end of the second vacuum valve 4 is connected to the molecular pump 3, and the other end...

PUM

| Property | Measurement | Unit |

|---|---|---|

| correction factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com