A fully automatic multi-tube capillary viscometer

A capillary viscometer, fully automatic technology, applied in the direction of DC flow characteristics measurement, material weighing, instruments, etc., can solve the problems of cumbersome operation steps, low precision, and inability to guarantee the same conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0078] The present invention will be further described below in conjunction with the accompanying drawings.

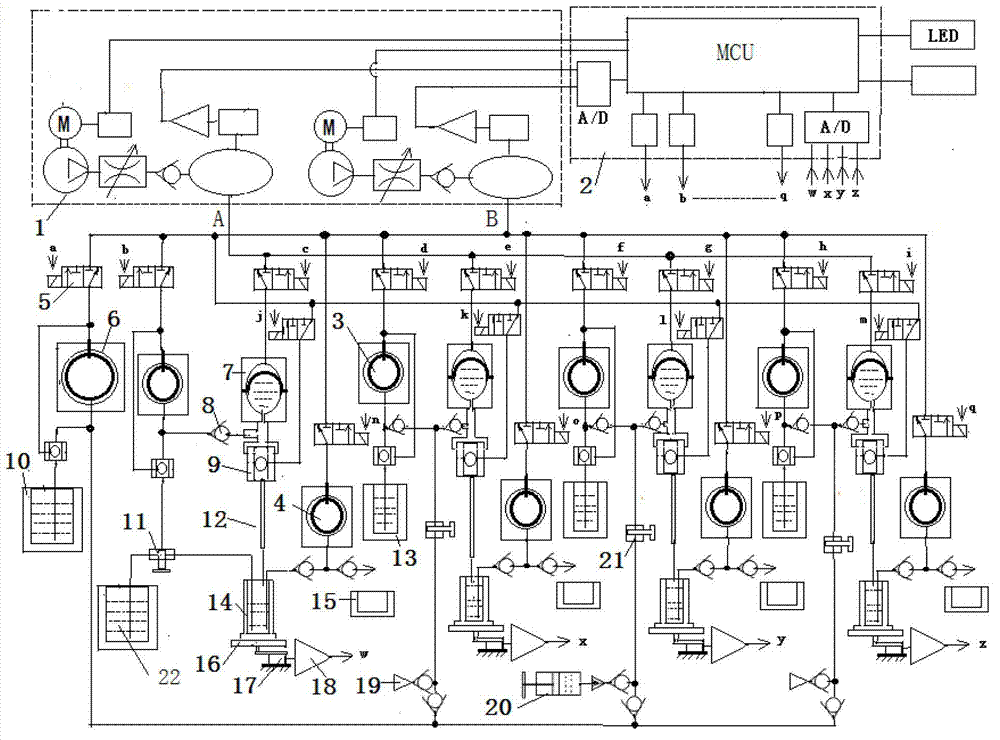

[0079] A fully automatic multi-tube capillary viscometer, such as figure 1 As shown, it includes control system 2, pneumatic system 1, reference liquid common injection circuit, reference liquid detection circuit and three sample detection circuits, among which,

[0080] The structure of the common injection circuit of the reference liquid is as follows: it includes the elastic air bag type pneumatic pump 6 and the reference liquid bottle I10, and the liquid inlet port of the elastic air bag type pneumatic pump 6 is connected to the pipeline of the reference liquid bottle I10;

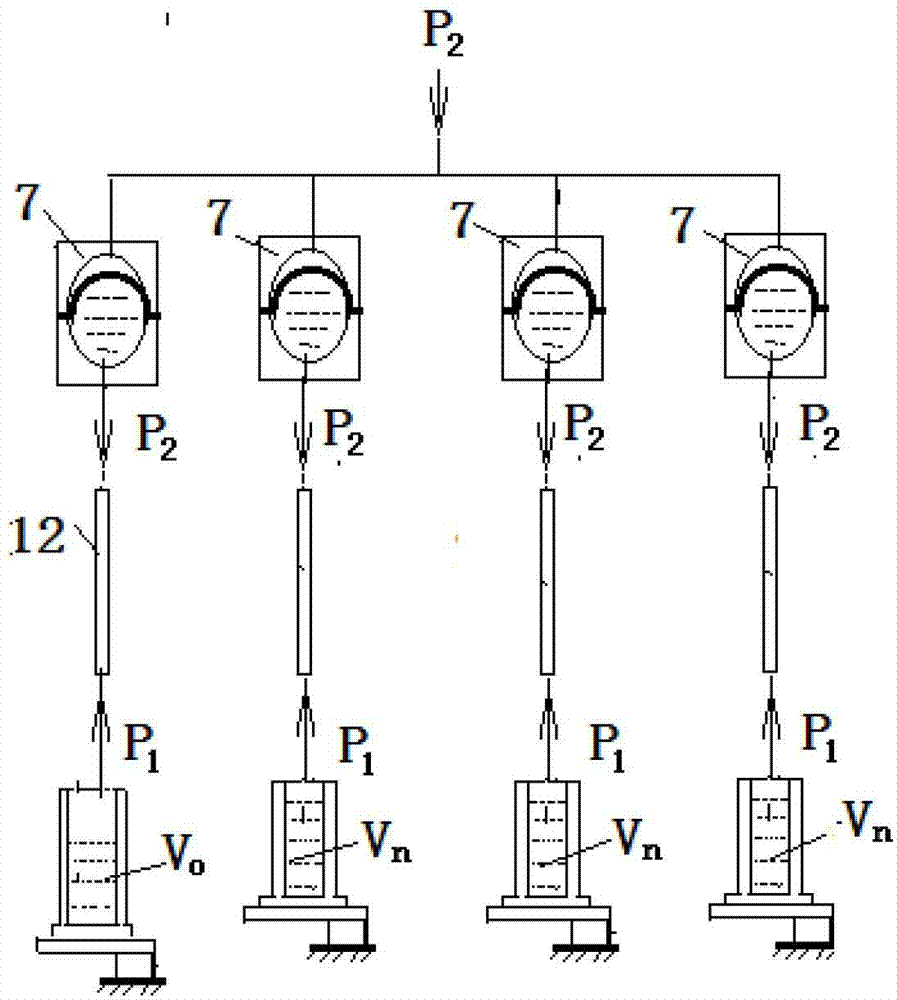

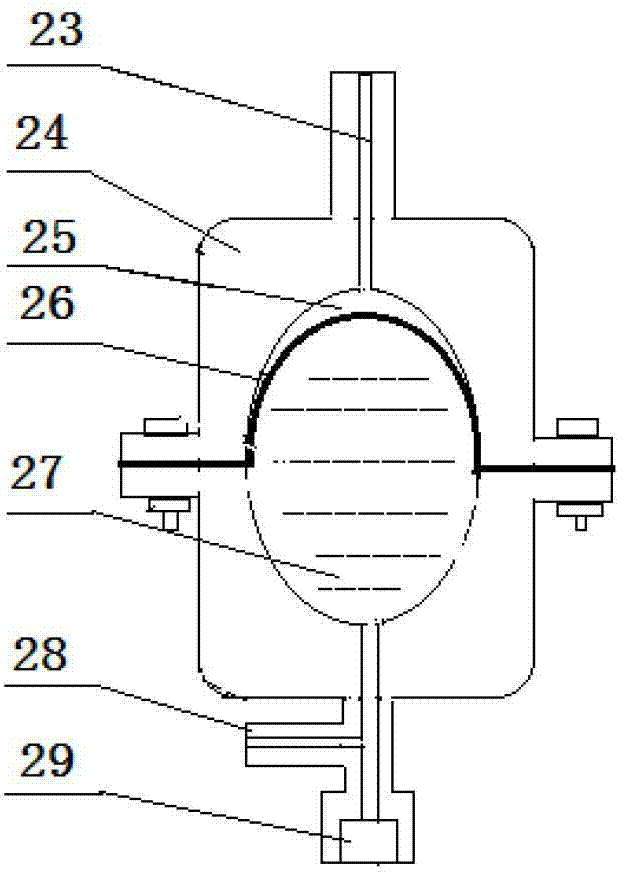

[0081] The structure of the reference liquid detection circuit is: comprising a reference liquid bottle II 22, a gas-liquid separator 7, a capillary 12, a weighing bottle 14, a weighing device (including a weighing pan 16, a load cell 17 and an amplifier 18, It is a conventional structure in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com