Production line for vacuum circuit breakers

A technology for production lines and vacuum circuit breakers, applied in circuits, electrical components, electrical switches, etc., can solve the problems affecting the production efficiency of production lines, consuming a lot of manpower and material resources, etc., to improve the consistency rate and production efficiency of assembly, and realize automatic The effect of recycling and saving human resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

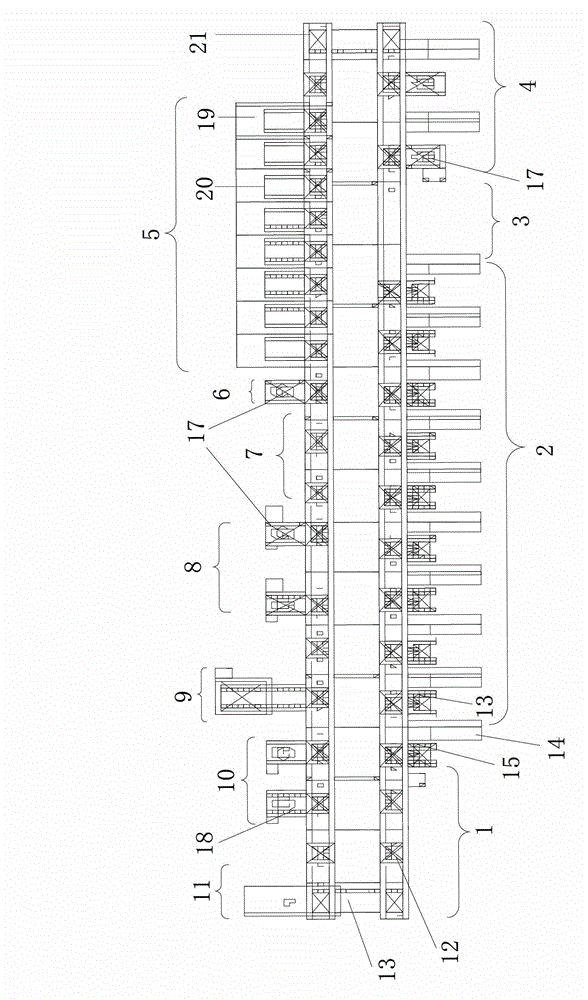

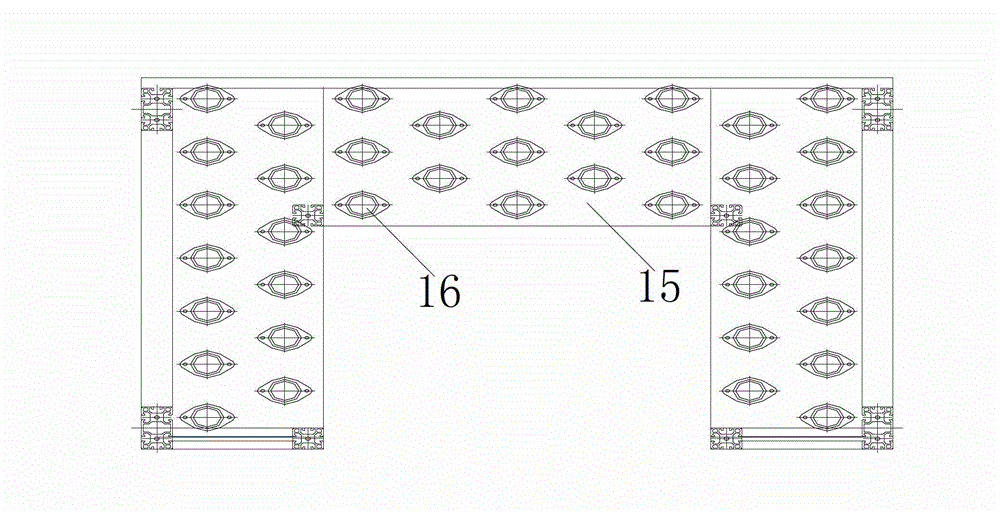

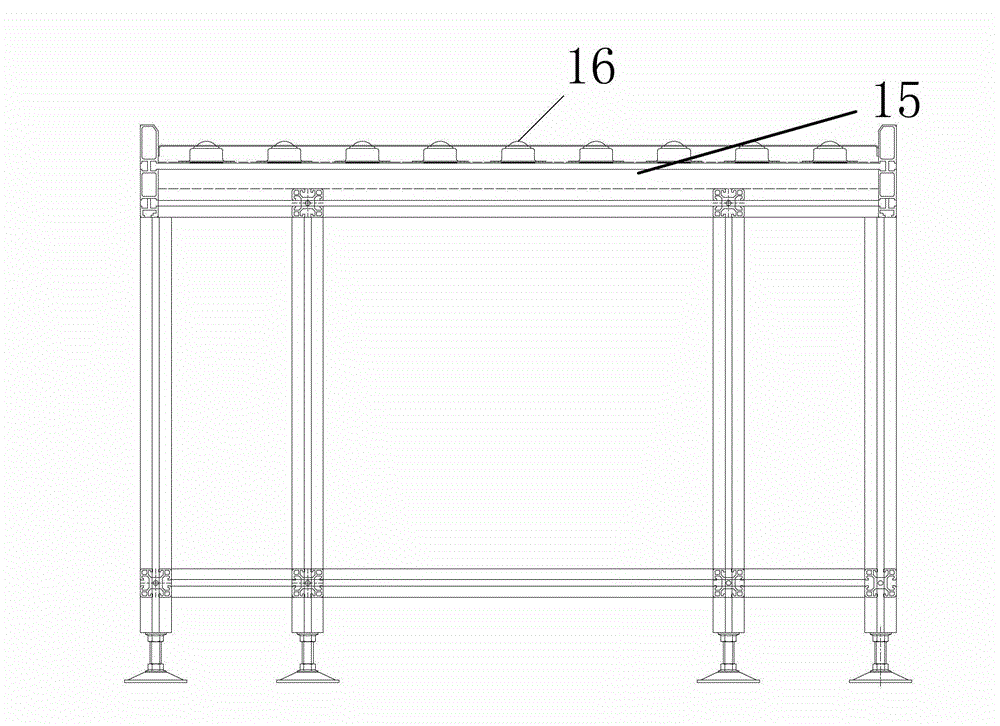

[0037] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that all the drawings of the present invention are in simplified form and use inaccurate scales, and are only used to facilitate and clearly assist the purpose of illustrating the embodiments of the present invention.

[0038] The present invention is a circulating assembly line equipped with a complete machine. By placing the vacuum circuit breaker on the tooling board and flowing on the automatic assembly line arranged in an O shape, the process of product assembly, running-in, testing, etc. is realized. The tooling board is returned to the original automatic production equipment. Wherein, the installation of the assembly line system in the workshop is based on the actual floor plan, which is not limited in the prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com