Method and system for rapid liquid filling forming of multilayer tube

A liquid-filled forming, multi-layer tube technology, applied in the field of multi-layer tube forming methods and systems, can solve the problems of high temperature medium transmission restriction, inability to withstand high temperature, etc., and achieve the effects of light weight, good stiffness and strength, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

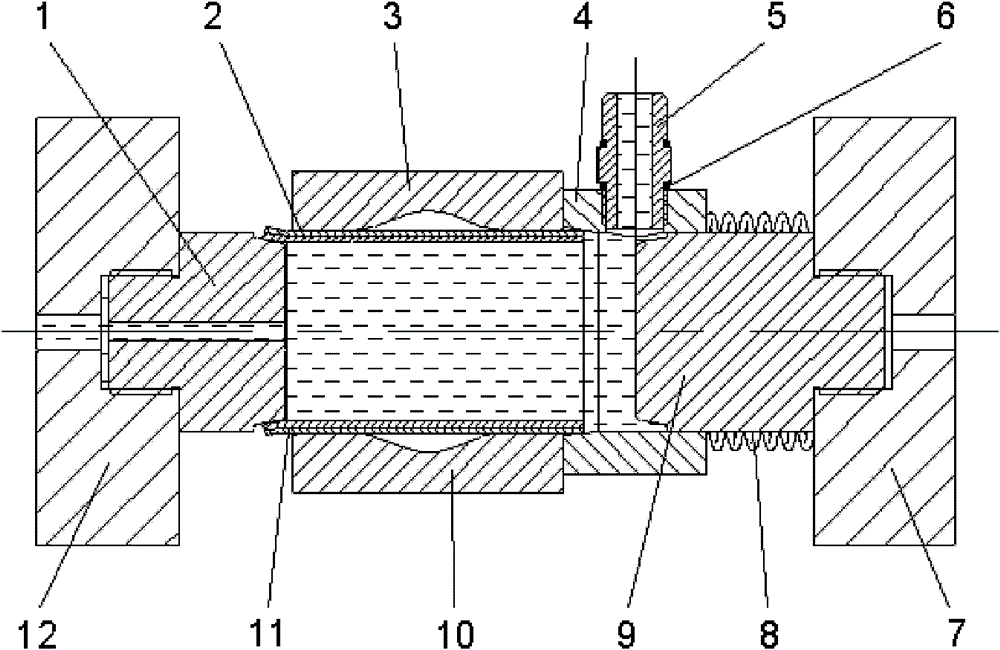

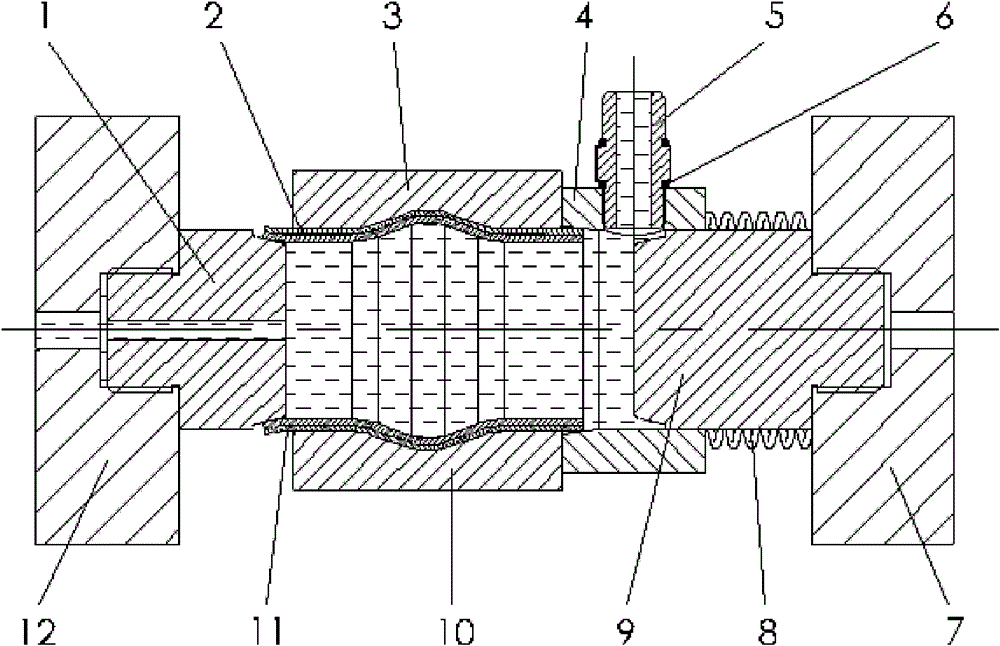

[0020] Such as figure 1 As shown, the mold used for forming has a left pusher 1, a right pusher 9, an upper half-mold 3 and a lower half-mold 10, and there are liquid chambers in the multilayer tubes 2 and 11, which are filled with forming medium, and the forming medium For example, it is liquid or other flexible media, which are liquids with good flow characteristics of various mineral oils, vegetable oils, edible oils, water and emulsions. Flexible media refer to rubber, molten metal, viscous media, such as non-Newtonian fluids such as silicone rubber, Not only at normal temperature, but also at high temperature, such as high temperature mineral oil, heat transfer oil, high temperature molten metal, solid powder particles, etc. Using high-temperature mineral oil, heat-conducting oil, high-temperature molten metal, solid powder particles, etc. as the liquid-filled medium can realize liquid-filled thermoforming, and realize the forming of complex thin-walled and difficult-to-f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com