Long-shaft roller carrier

A roller frame and long shaft technology, applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problem of not being able to match short cylinder groups, and achieve the effect of simple structure and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

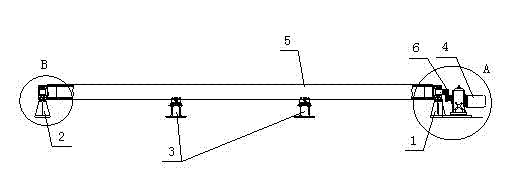

[0020] like Figure 1 to Figure 6 As shown, a long-axis roller stand includes an active support 1 and a driven support 2, two center frames 3 are arranged between the active support 1 and the driven support 2, and a pair of parallel rollers 5 are supported by the active support. Seat 1,

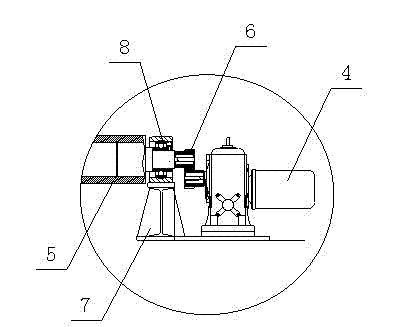

[0021] The driven support 2 is supported by the center frame 3, and one end of the roller shaft 5 located at the driving support 1 is connected to the output shaft of the worm gear reducer 4 through the gear set 6 to realize rotation.

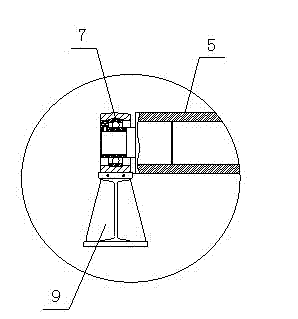

[0022] The active support 1 includes an active base 7 on which a bearing 8 is installed; the driven support 2 includes a driven base 9 on which a bearing 7 is installed.

[0023] Described center frame 3 comprises center frame base 10, and the roller 11 of supporting roller shaft 5 is set on the center frame base 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com