Automatic push mounting system of automotive combination meter pointer

A combination meter pointer and automatic technology, used in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of unqualified products, easily crushed meters, falling off, etc., to reduce the scrap rate, avoid pointer falling off, and ensure accuracy. The effect of positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

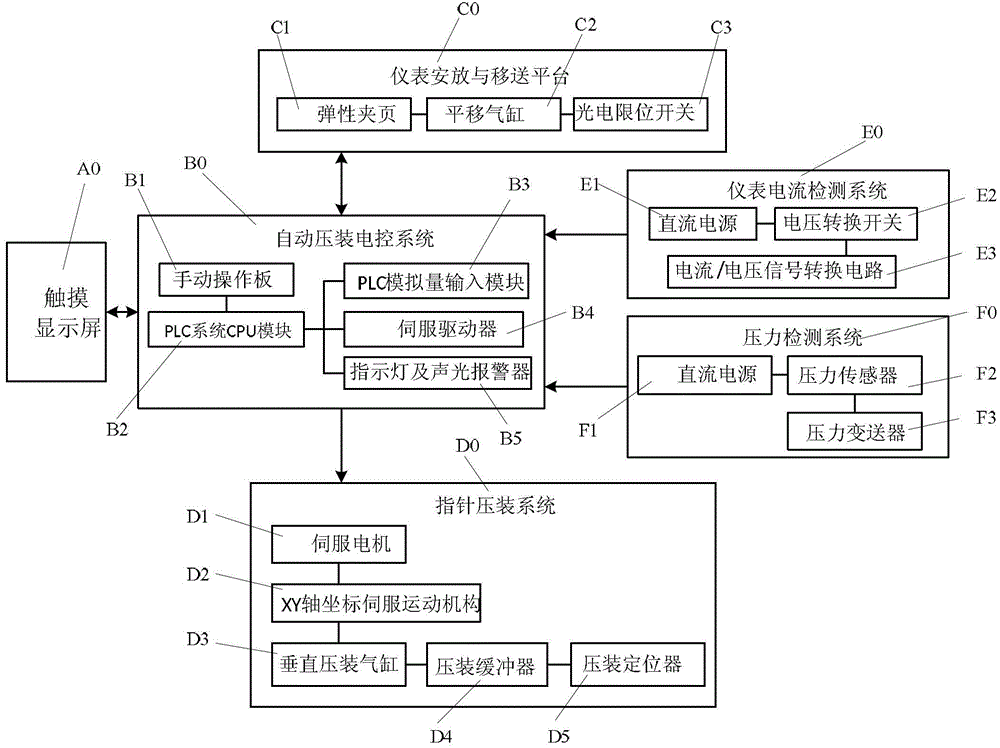

[0039] An automatic press-fitting system for the pointer of an automobile combination instrument, its functional structure block diagram can be found in figure 1 , the system includes a touch screen A0, an automatic press-fit electronic control system B0, an instrument placement and transfer platform C0, a pointer press-fit system D0, an instrument current detection system E0, and a pressure detection system F0; the automatic press-fit electronic control system B0 The input and output terminals of the instrument are respectively connected with the output and input terminals of the instrument placement and transfer platform C0 and the touch screen A0. The input terminal of the automatic press-fitting electronic control system B0 is also connected with the output terminals of the pressure detection system F0 and the instrument current detection system E0. The output end of the automatic press-fitting electronic control system B0 is also connected to the input end of the pointer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com