Cutting method and cutting machine of sheet glass

A technology of flat glass and cutting method, which is applied in the direction of glass cutting device, glass production, glass manufacturing equipment, etc. It can solve the problems of low cutting efficiency, large bending angle, low efficiency and low yield rate, so as to improve yield rate and reduce operation Effects of loss and productivity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the objectives, technical solutions and advantages of the present invention clearer, the following further describes the present invention in detail with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

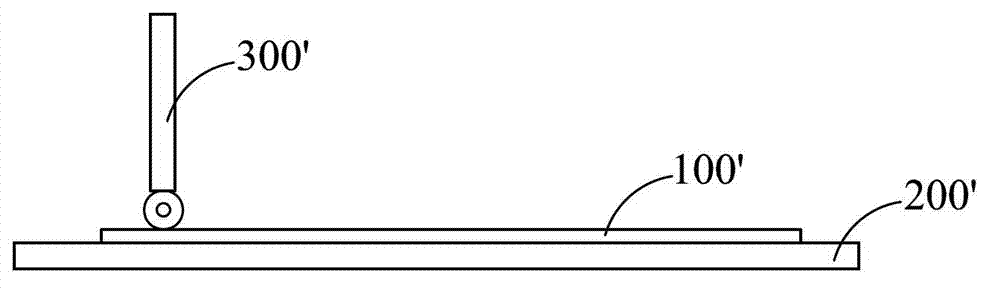

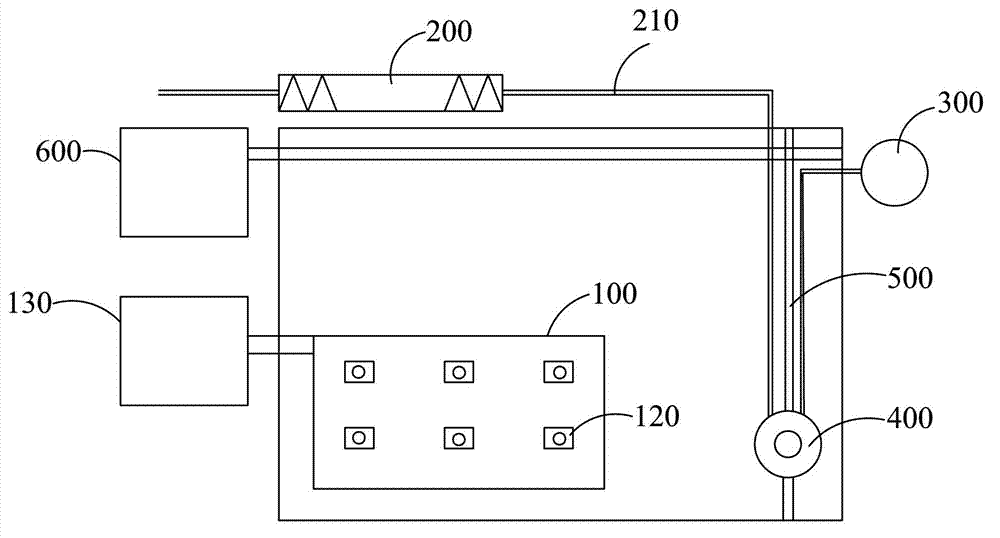

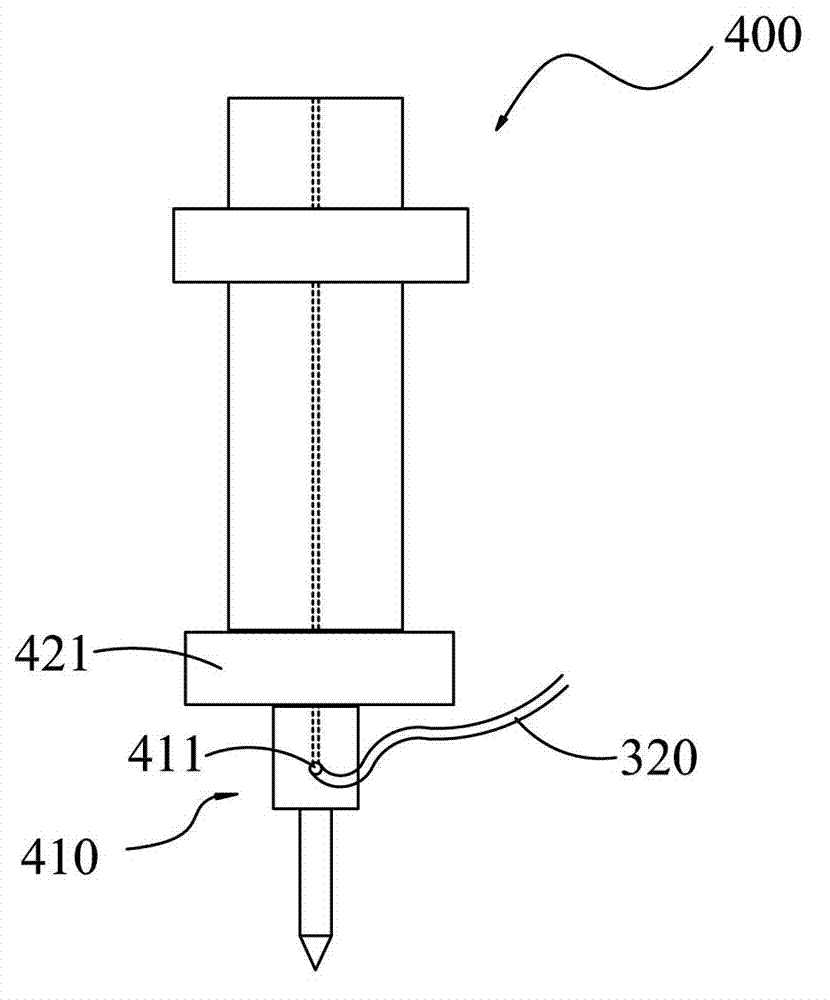

[0017] The present invention provides a method for cutting thin plate glass, where thin plate glass generally refers to glass with a thickness of 0.33 mm to 1.5 mm. The cutting method includes the following steps: firstly, a plurality of sheets of flat glass are laminated and bonded together; then, the bonded sheet glass is fixed and cut by a water-sand mixed jet. The water-sand jet has a strong cutting force, and there is no need to break the pieces after the cutting is completed, which reduces man-made operation losses and improves the yield rate. The present invention also provides a thin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com