Method for strengthening and repairing pile head of hollow square pile

A hollow square pile and square pile technology, applied in sheet pile wall, construction, infrastructure engineering and other directions, can solve the problems of accelerated construction progress, increased cost, broken pile head, etc., to reduce the probability of re-destruction and save money The effect of engineering cost and avoiding stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

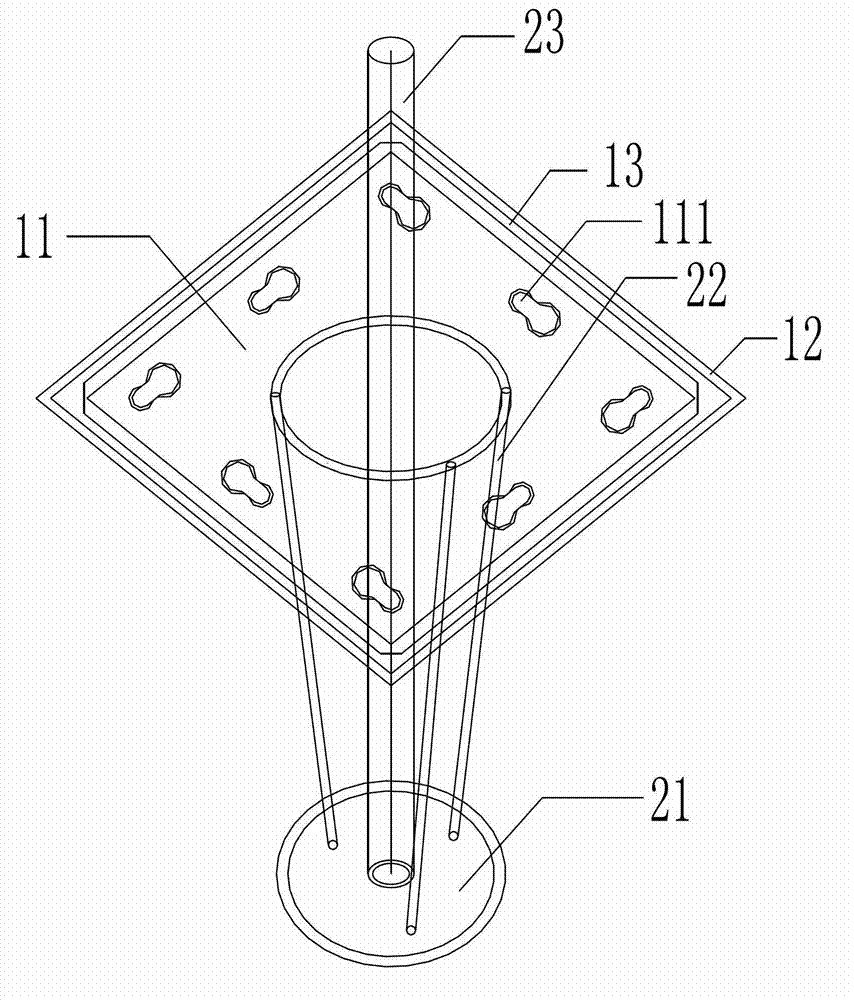

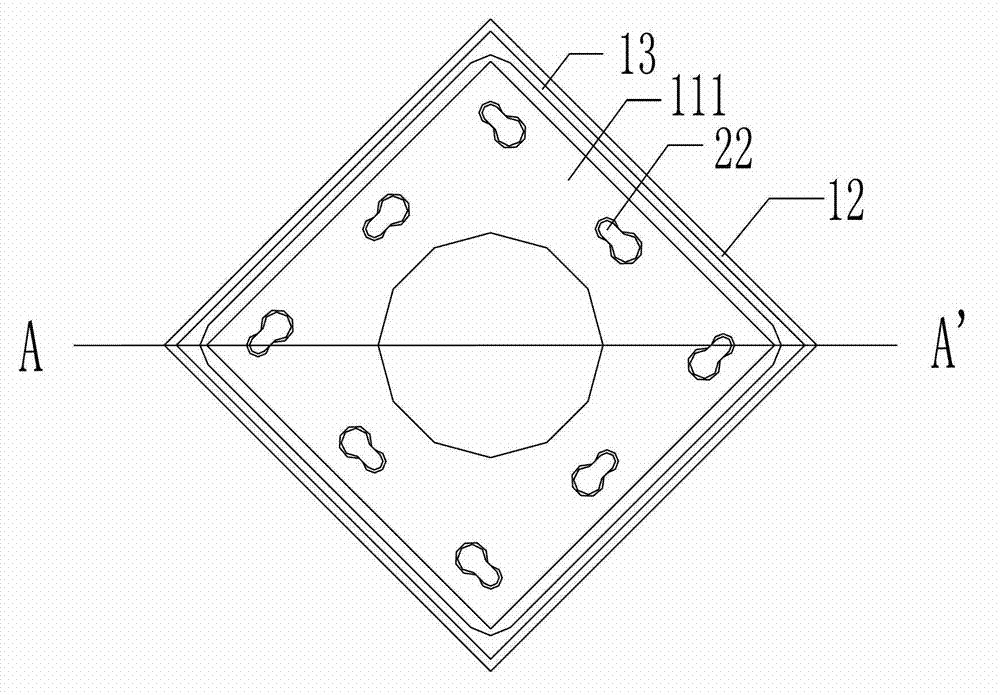

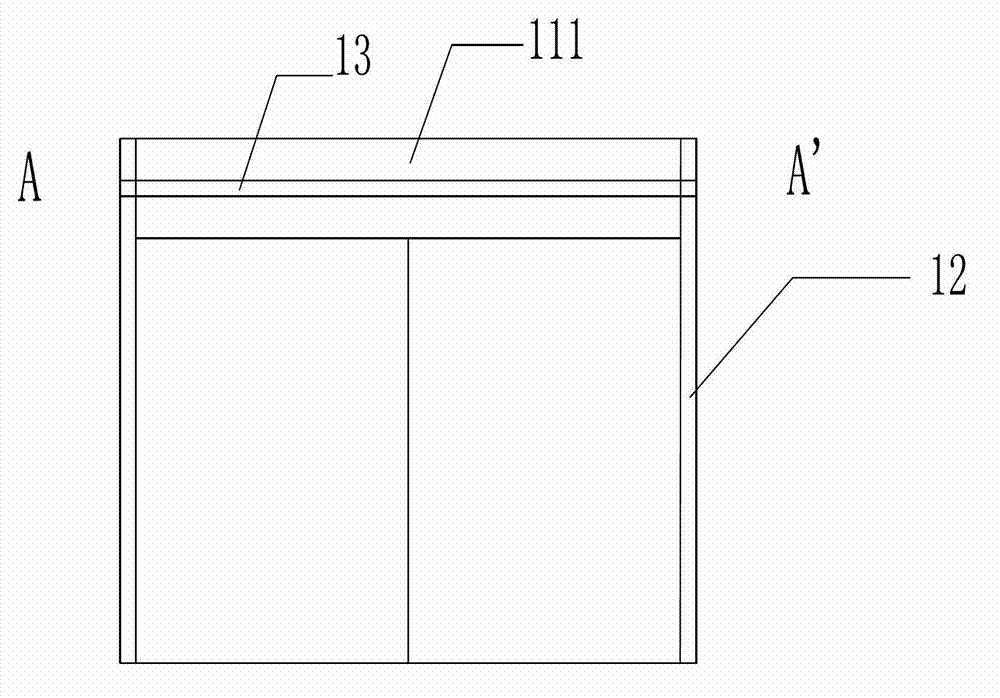

[0021] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail. figure 1 It is a structural schematic diagram of the present invention, such as figure 1 As shown: the present invention includes the following steps: (1). Remove the damaged and loose concrete on the square pile head that needs to be repaired, expose the main reinforcement 3-4cm and straighten the main reinforcement to make the main reinforcement plumb; then remove the floating ash of the concrete by washing And the soil, after natural drying, add a pile cap of the same specification on the pile head, and connect the exposed main reinforcement with the pile cap, wherein, the pile cap includes: a square end plate 11, and the square end plate 11 is sleeved There is a square steel hoop 12, the non-processed surface of the square end plate 11 is coplanar with the end face of the square steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com