Bottle valve for shock-proof dry powder extinguishing devices

A dry powder fire extinguishing, bottle head valve technology, applied in valve devices, devices to prevent accidental or unauthorized action, valve details, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

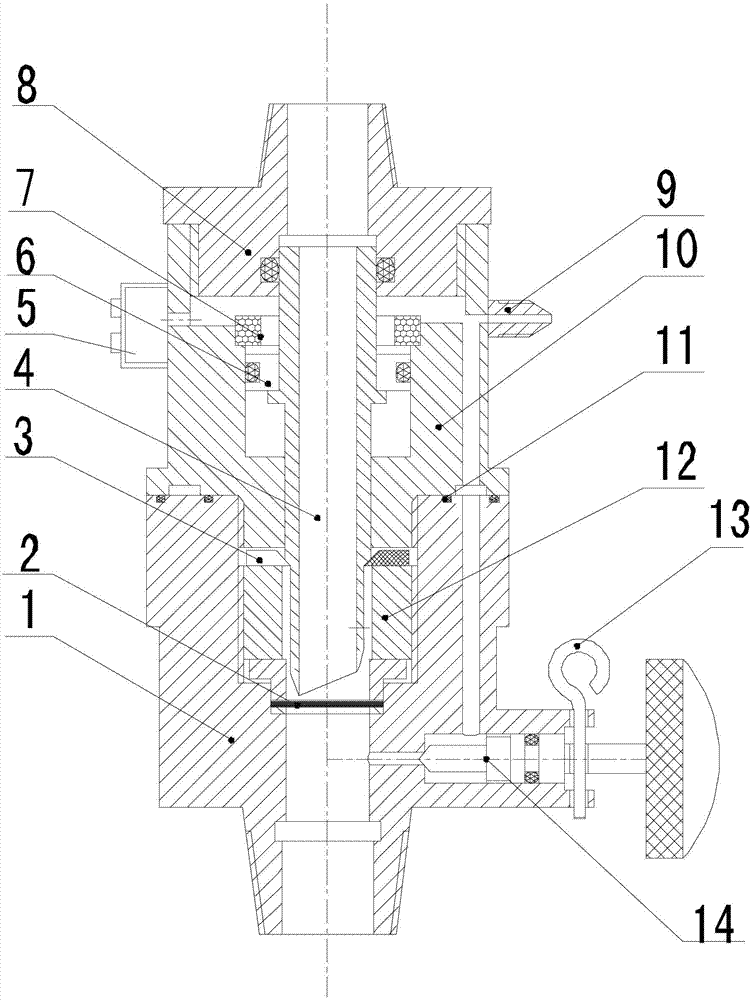

[0022] refer to figure 1 , is a kind of anti-shock type dry powder fire extinguishing device bottle head valve of the present invention. Wherein, it includes a lower valve body 1 with a first stepped through hole, an upper valve body 10 threaded in the upper part of the lower valve body 1 , and an upper valve cover 8 threaded in the upper part of the upper valve body 10 . The upper valve body 10 is provided with a second stepped through hole coaxial with the first stepped through hole, a puncture needle 4 runs through the second stepped through hole, and a piston 6 is set on the upper part of the puncture needle 4, and the second stepped through hole The lower hole is in clearance fit with the puncture needle 4, and the upper hole is slidably matched with the piston 6; a diaphragm 2 is provided at the bottom of the upper hole of the first step through hole, and a pressure ring 12 is arranged on the diaphragm 2, and the pressure ring 12 compresses the film Sheet 2, pressure ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com