Wind wheel (with filter screen) for range hoods

A range hood and belt filter technology, which is applied in the field of kitchen range hood wind wheel structure, can solve the problems of affecting the normal use of the motor, poor filtering and separation effect of oil fume, and reduced separation effect of oil fume, achieving good separation rate, Guaranteed effect and improved separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

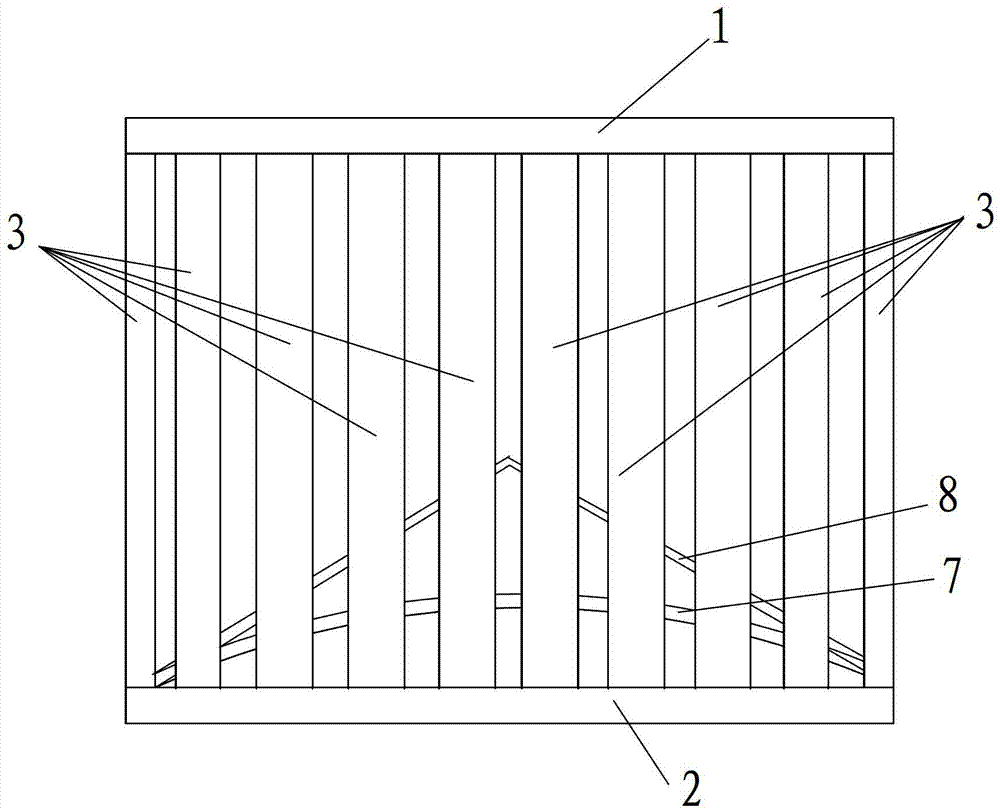

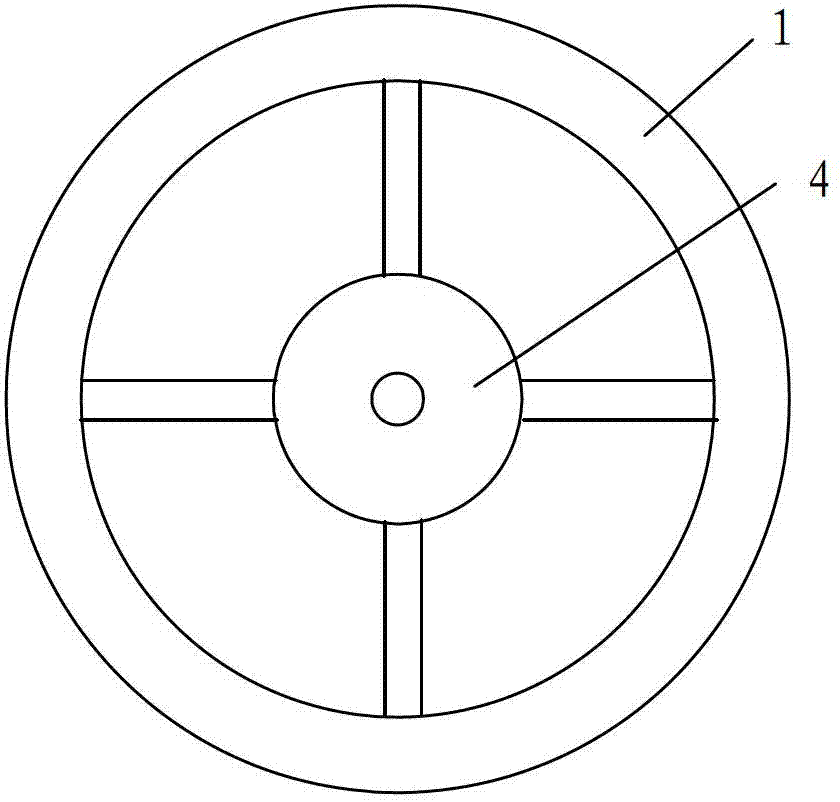

[0025] like figure 1 , 2 As shown, the first support ring 1 and the second support ring 2 are connected by blades 3 arranged at intervals along the circumference. The space between the blades 3 forms a channel wind space. A bracket 4 for the driving device is provided on the first support ring 1 . The space between the annular hole of the second support ring 2 , the first support ring 1 and the blades 3 forms a suction space.

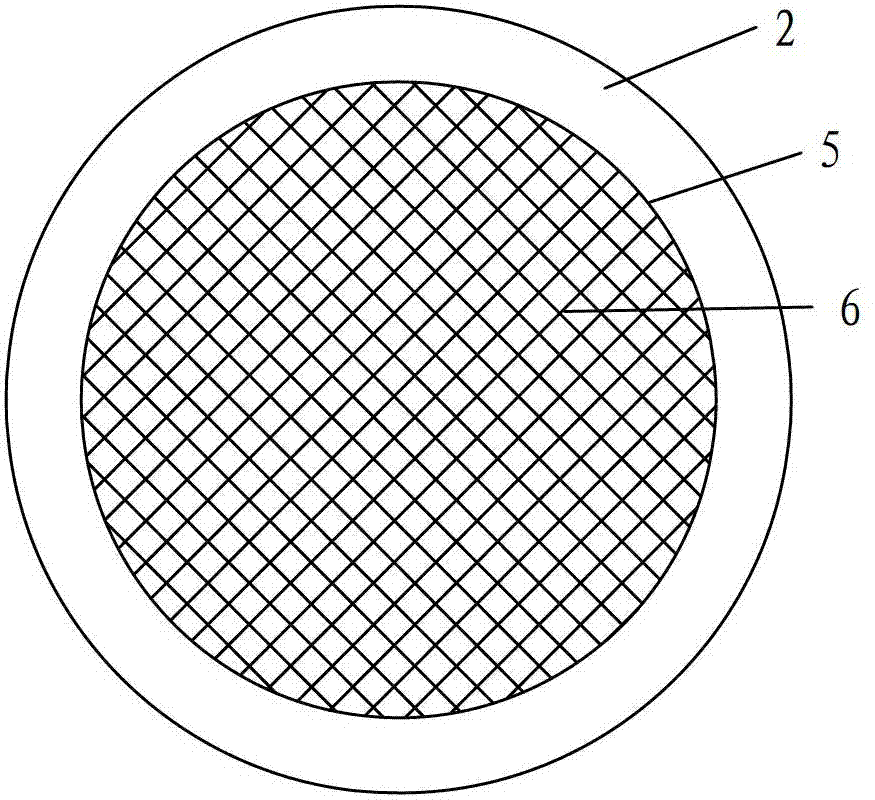

[0026] like image 3 As shown, the second support ring 2 is connected with a filter screen, and the filter screen covers the ring hole 5 of the second support ring.

[0027] The filter screen is a multi-layer filter screen. There is an oil fume separation space between the multi-layer filter screens.

[0028] In this embodiment, three layers of filter screens are adopted, such as Figure 4 As shown, the first layer of filter screen is a plane filter screen 6 connected on the second support ring, and the second layer of filter screen is an arc fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com