Plate radiator of sloping-shoulder transformer

A technology for transformers and radiators, applied in transformer/inductor cooling, heat exchanger types, indirect heat exchangers, etc., can solve the problem of low heat dissipation efficiency of transformer chip radiators, and achieve novel structure and improved heat exchange efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

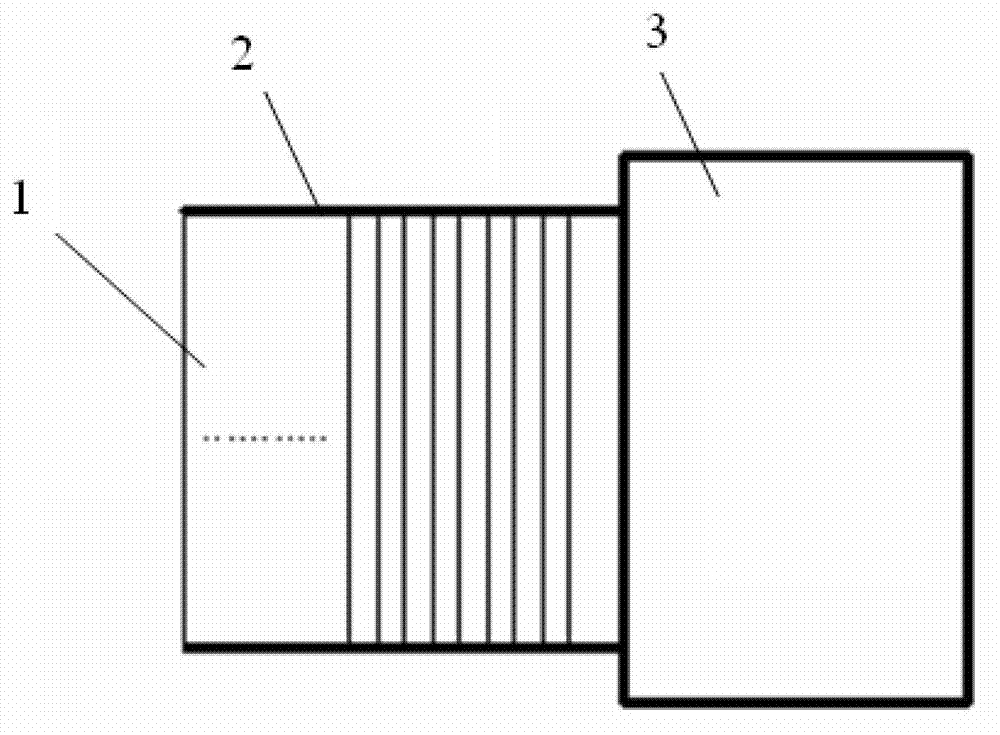

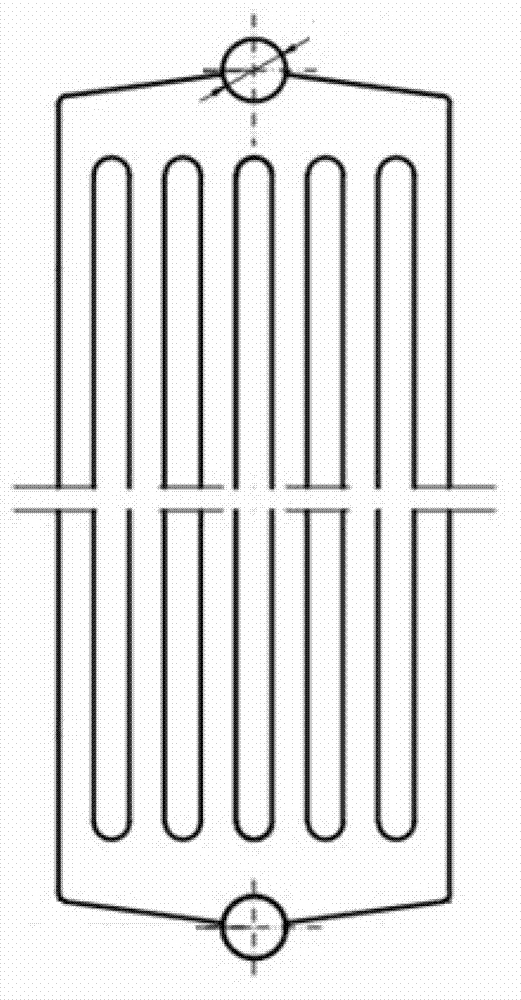

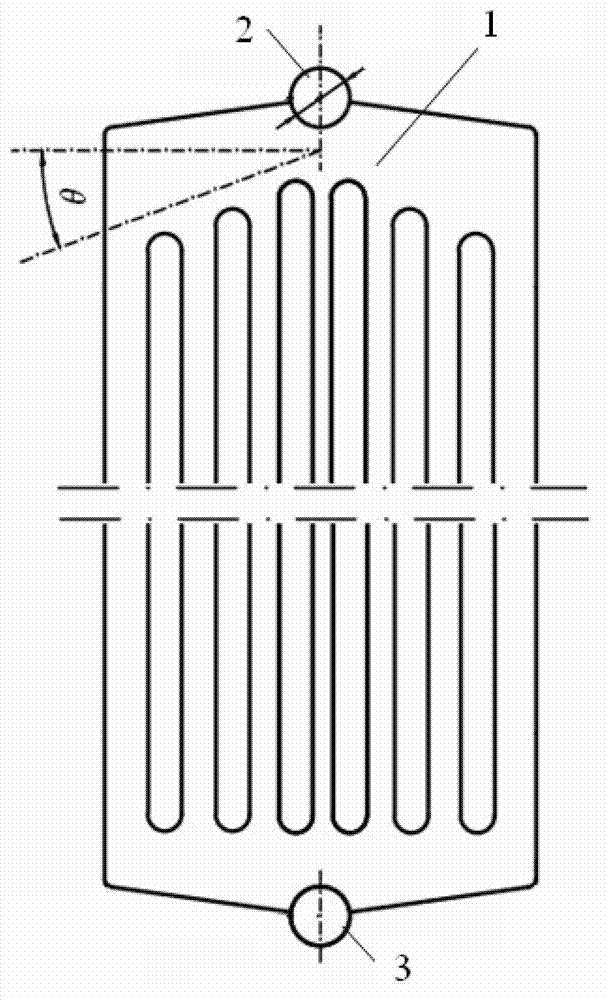

[0037]The unit box 1 of the double sloping shoulder type transformer chip radiator is installed parallel to each other, the upper oil collecting pipe 2 and the lower oil collecting pipe 3 are respectively connected with the unit box 1 of the double sloping shoulder type transformer chip radiator, and the upper oil collecting pipe 2 is connected with the horizontal clip horn β for 10 o The structure of the double sloping shoulder type transformer chip radiator unit box 1 is: the main body 101 has an upper oil collecting pipe inlet 102, a lower oil collecting pipe outlet 104, an oil passage 103 is arranged inside the main body, and the middle part of the oil passage is a high point, and sloped shoulder angles to both sides θ for 13 o , the width of the oil channel of the double-sloping-shouldered transformer chip radiator unit box gradually increases from the middle to both sides according to the arithmetic sequence, and the tolerance d =3mm.

Embodiment 2

[0039] The unit box 1 of the double sloping shoulder type transformer chip radiator is installed parallel to each other, the upper oil collecting pipe 2 and the lower oil collecting pipe 3 are respectively connected with the unit box 1 of the double sloping shoulder type transformer chip radiator, and the upper oil collecting pipe 2 is connected with the horizontal clip horn β for 15 o The structure of the double sloping shoulder type transformer chip radiator unit box 1 is: the main body 101 has an upper oil collecting pipe inlet 102, a lower oil collecting pipe outlet 104, an oil passage 103 is arranged inside the main body, and the middle part of the oil passage is a high point, and sloped shoulder angles to both sides θ 16.5 o , the width of the oil channel of the double-sloping-shouldered transformer chip radiator unit box gradually increases from the middle to both sides according to the arithmetic sequence, and the tolerance d =3mm.

Embodiment 3

[0041] The unit box 1 of the double sloping shoulder type transformer chip radiator is installed parallel to each other, the upper oil collecting pipe 2 and the lower oil collecting pipe 3 are respectively connected with the unit box 1 of the double sloping shoulder type transformer chip radiator, and the upper oil collecting pipe 2 is connected with the horizontal clip horn β for 20 o The structure of the double sloping shoulder type transformer chip radiator unit box 1 is: the main body 101 has an upper oil collecting pipe inlet 102, a lower oil collecting pipe outlet 104, an oil passage 103 is arranged inside the main body, and the middle part of the oil passage is a high point, and sloped shoulder angles to both sides θ for 20 o , the width of the oil channel of the double-sloping-shouldered transformer chip radiator unit box gradually increases from the middle to both sides according to the arithmetic sequence, and the tolerance d =3mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com