Mini-cultivator speed-change mechanism

A technology of variable speed mechanism and micro-tiller, which is applied to agricultural machinery and implements, agricultural machinery, mechanical equipment, etc., can solve the problems of low reliability, slow driving speed, and inflexible speed changes, and achieves high reliability and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

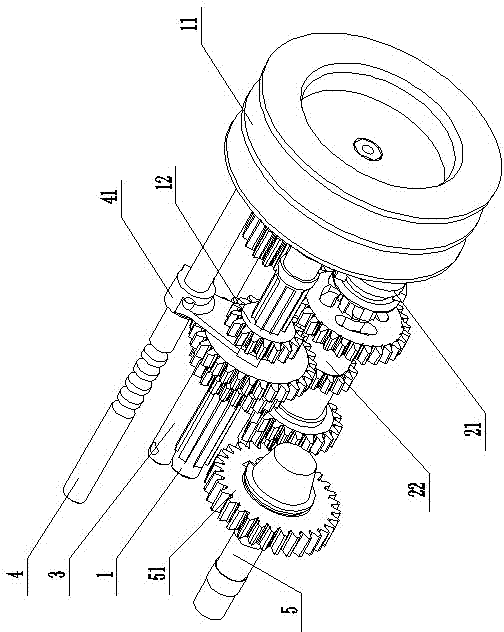

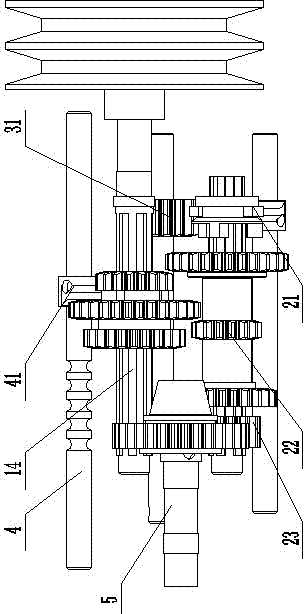

[0010] Such as figure 1 and 2 As shown, the present invention provides a speed change mechanism for a tiller, comprising a driving shaft 1, a driven shaft 2, a reverse gear shaft 3, a shift fork shaft 4 and an output shaft 5, and the driving shaft 1 is provided with a belt driven wheel 11 and The driving triple gear 12 that can move axially along the driving shaft 1, the driven shaft 2 is provided with a clutch gear 21 that can move along its axial direction, a driven triple gear 22 that is rotatably matched with it, and a driven gear fixed on the driven shaft. The drive shaft output gear 23, the reverse gear shaft 3 is provided with a reverse gear 31, the shift fork shaft 4 is provided with a shift fork 41, and the output shaft 5 is provided with a driving gear 51 which is constantly meshed with the driven shaft output gear 23 .

[0011] The axial center of the driving triple gear 12 is provided with tooth grooves, the surface of the driving shaft 1 is provided with bar tee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com