Full-automatic environmental-friendly energy-saving pulp cooking unit

An environmentally friendly, energy-saving, fully automatic technology, applied in milk substitutes, beverage preparation devices, household appliances, etc., can solve the problems of water waste, large equipment area, backward process, etc., to avoid pollution, save water resources, The effect of saving production area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

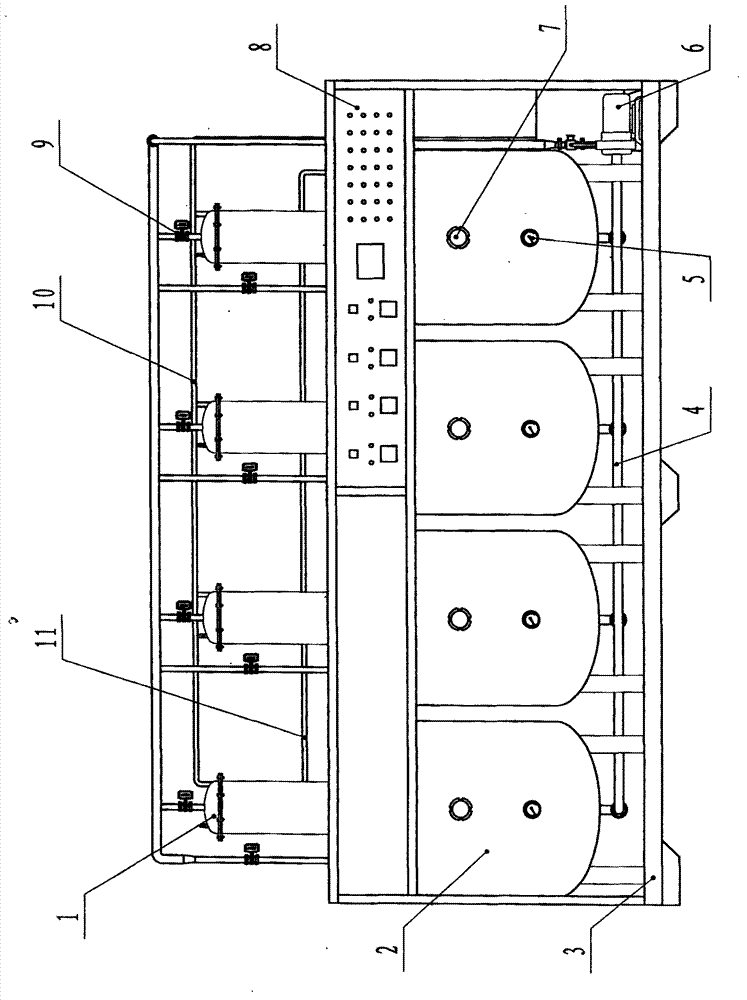

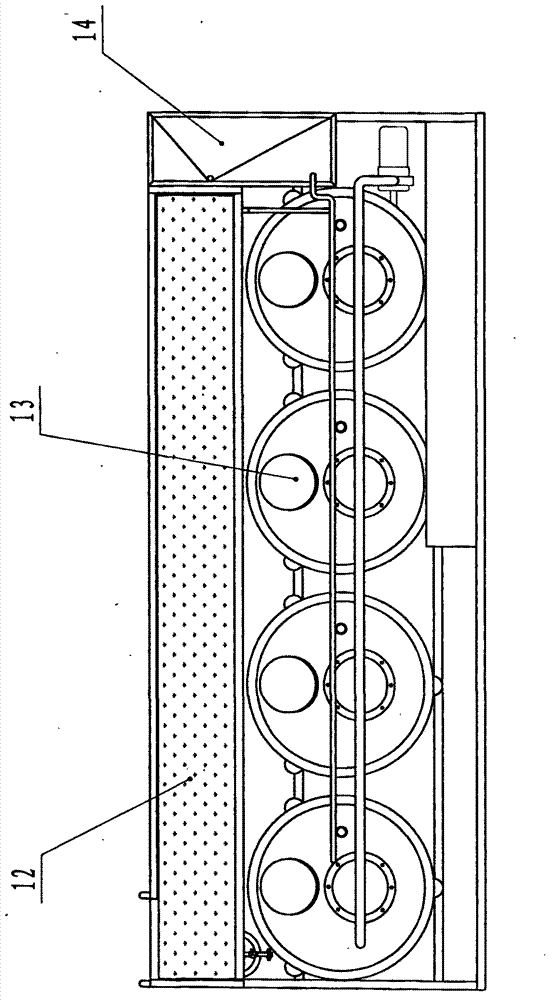

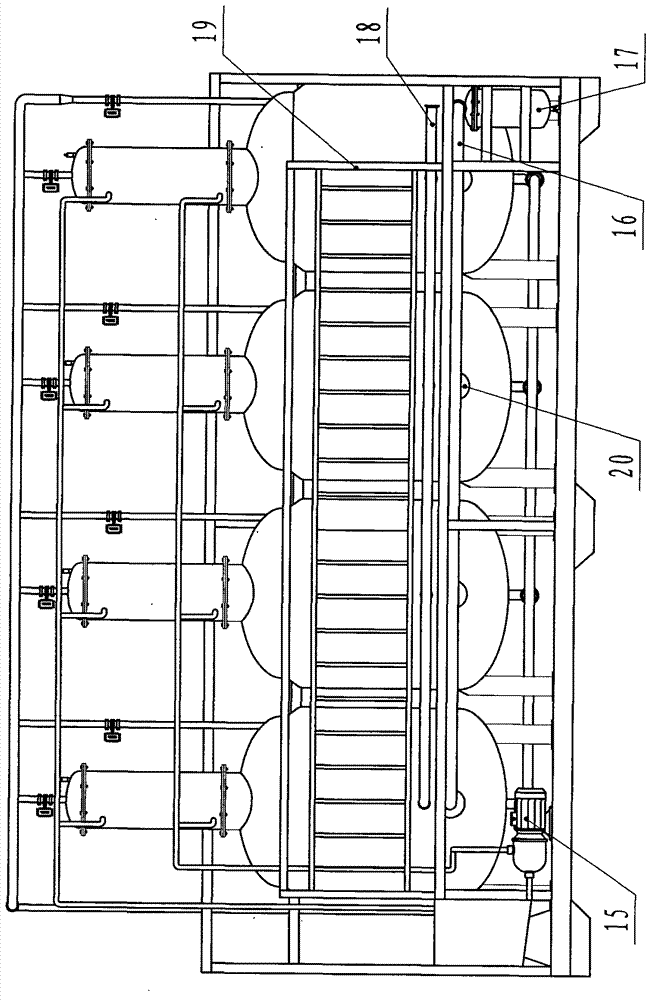

[0013] A fully automatic environment-friendly and energy-saving pulp cooking unit, comprising a frame 3 and an electric control box 8, a pulp cooking tank 2 is arranged on the frame 3, and a pulp feeding pipeline 18 and a manhole 13 are respectively arranged on the pulp cooking tank 2 , an observation window 7 and a tank temperature sensor 5, a pulping pipeline 4 and a pulping pump 6 are arranged at the bottom of the pulping tank 2, and a steam electric control valve 20 and a steam electric control valve 20 and a steam valve 20 are respectively arranged on the steam input pipe 16 of the pulping tank 2. The filter 17, the tank temperature sensor 5, the slurry pump 6 and the steam electric control valve 20 are all electrically connected with the electric control box 8 respectively, and the condensation tank 1 communicates with the top cover 22 of the pulp cooking tank 2 through the flange 23, and the condensation tank 1 is provided with a condensate pipe fixing plate 24, a vertic...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap