Pressure feeding three-product dense medium cyclone for high-density sorting

A technology of dense medium cyclone and cyclone, which is applied in the direction of cyclone device, the device whose axial direction can be reversed, solid separation, etc., can solve the problem of affecting the separation efficiency and quality, and can not be effective for non-magnetic minerals. Sorting and other issues, to achieve the effect of low cost, high grade concentrate products and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

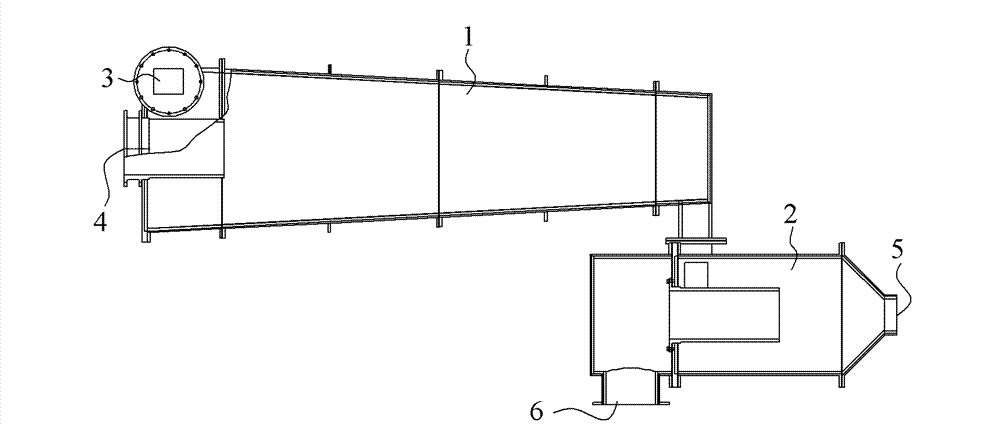

[0009] The present invention will be further described below in conjunction with the accompanying drawings.

[0010] like figure 1 As shown, the pressurized feeding type three-product dense medium cyclone for high-density separation of the present invention is connected with the pressure feeding primary cyclone 1 and the pressure feeding secondary cyclone 2 through pipelines. The cone angle of the primary cyclone 1 is 5°-20°, the conical part of the secondary cyclone 2 is designed with a large cone angle, and the cone angle is 30°-180°, and one end of the primary cyclone 1 is provided with an inlet An interface 3 and a concentrate outlet 4; one end of the secondary cyclone 2 is provided with a tailings outlet 5, and the bottom of the secondary cyclone 2 is provided with a middle ore outlet 6. The installation inclination angle of the primary cyclone 1 is 30°-60°, and the primary cyclone 1 and the secondary cyclone 2 are installed horizontally.

[0011] The above is only a pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cone angle | aaaaa | aaaaa |

| Cone angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com