A dissociation and re-election process of coking powder mid-coal

A technology for dissociation of fine coal, applied in solid separation, grain treatment, etc., can solve the problems of clean coal polluted tailing coal ash content, flotation clean coal ash content exceeding the standard, etc., to reduce energy consumption, avoid pollution, and low operating costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

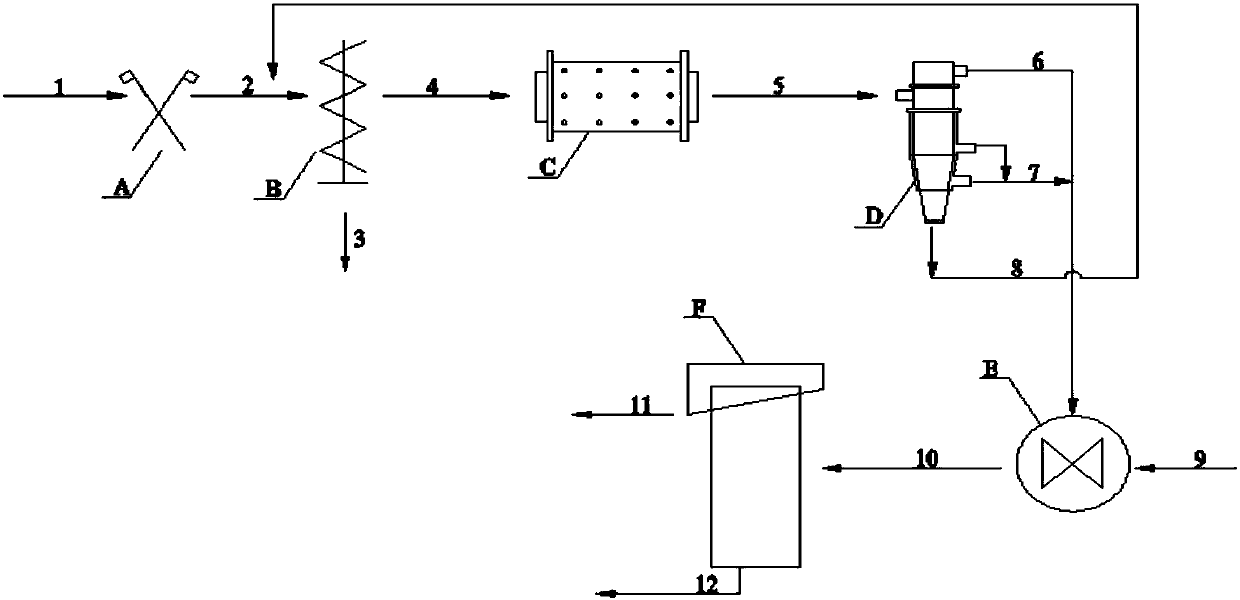

[0016] The specific embodiment of the present invention is further described below in conjunction with accompanying drawing:

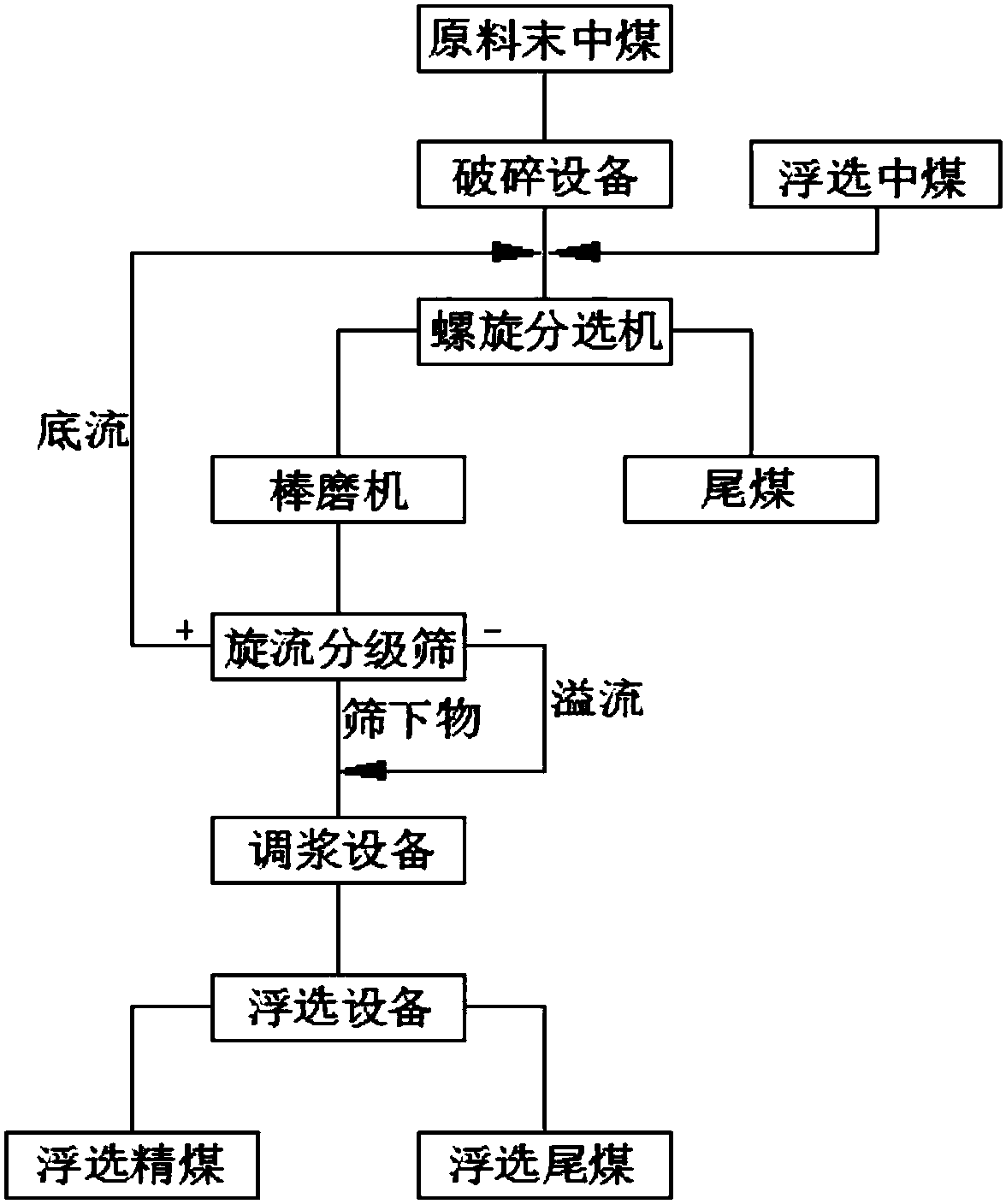

[0017] Such as figure 1 Shown, the dissociation and reselection process of coal in the coking powder of the present invention, its steps are as follows:

[0018] a. Feed the middling coal as raw material into a reversible hammer crusher for preliminary crushing and dissociation, the upper limit of the particle size of the middling coal is 13mm; feed the crushed products after preliminary crushing and dissociation into a spiral separator for pulping , after pulping, start the spiral separator for sorting, and the upper limit of the broken particle size is 1mm;

[0019] b. After separation by the spiral separator, high-ash tailing coal and coarse clean coal are produced. Among them, the high-ash tailing coal is discharged, and the coarse clean coal is fed into the short body mill for grinding to obtain rough clean coal after grinding. product, the shor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com