Low-pressure feeding two-product heavy-medium cyclone for realizing high-density sorting of low-density medium

A dense medium cyclone and cyclone technology, which is applied in the direction of the swirl device, the device whose axial direction of the swirl can be reversed, etc., can solve the problem of high feeding pressure, short life, three-product dense medium cyclone Wear and other problems, to achieve the effect of reducing feeding pressure, low production cost, and reducing pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing, the present invention will be further described

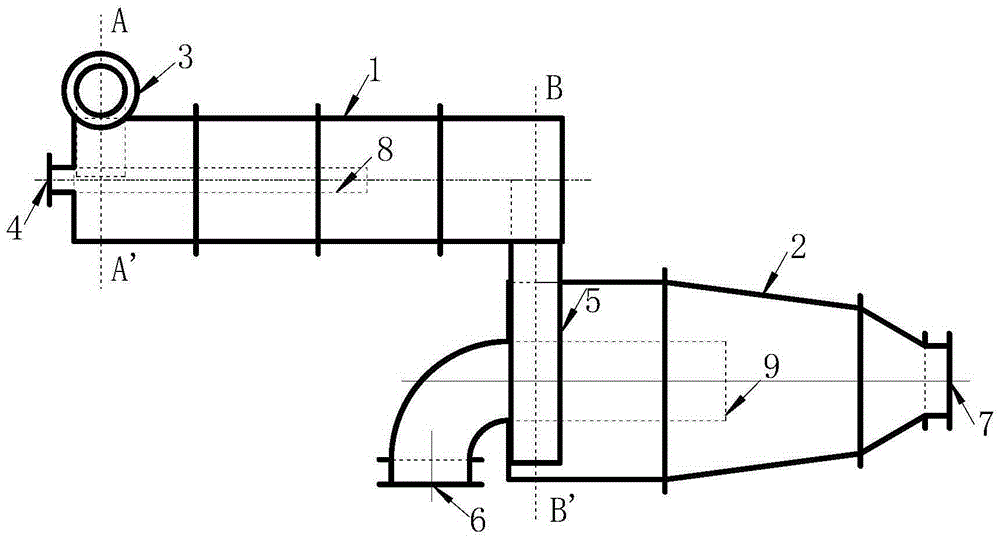

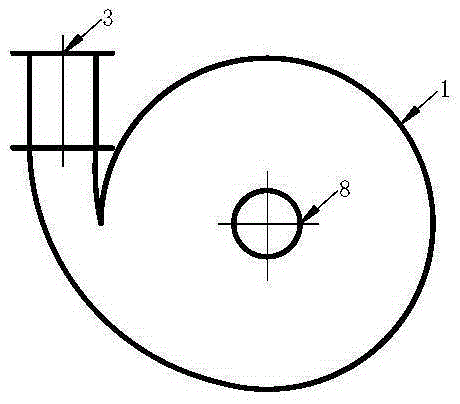

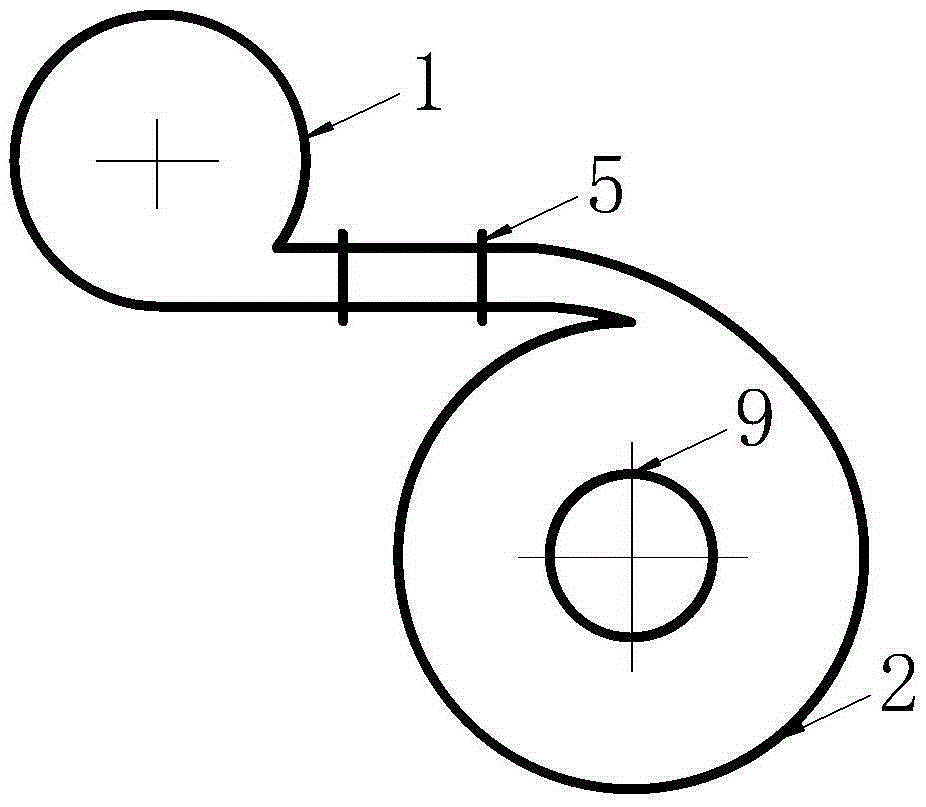

[0015] Such as figure 1 As shown, the present invention is a low-pressure feeding two-product heavy-medium cyclone that realizes high-density separation of low-density medium, which is divided into a concentration stage and a sorting stage, and a cylindrical one-stage concentration cyclone connected by pipelines (1) and the cylindrical conical secondary separation cyclone (2), the primary concentration cyclone (1) is a cylindrical cyclone, and the ratio of the cylinder diameter to the maximum particle diameter is 8-12 , The ratio of the diameter of the feed pipe (3) to the diameter of the cylinder is 0.3-0.4, the cone ratio is 1.6-2.4 and the insertion depth of the overflow pipe (8) is steplessly adjustable; the secondary separation cyclone (2) is Cylindrical conical cyclone, the conical angle of the conical part is 5°-20°, the cone angle of the conical part is 40°-90° and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com