Sliding base specially used for BOPET (biaxially-oriented polyethylene terephthalate) sheet

A two-way stretching, sliding seat technology, used in applications, home appliances, flat products, etc., can solve the problems of non-adjustable sliding seat, guide rail cannot be freely retracted, jamming, etc., to achieve stable and reliable dynamic sliding of guide rail, and reduce products. Scrap rate, easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

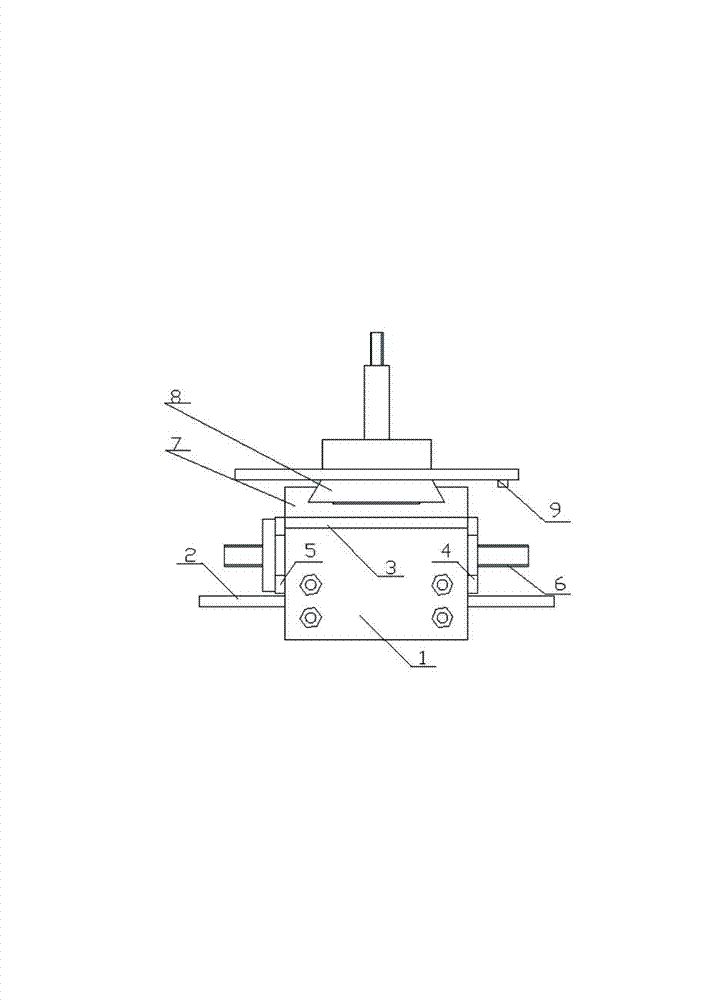

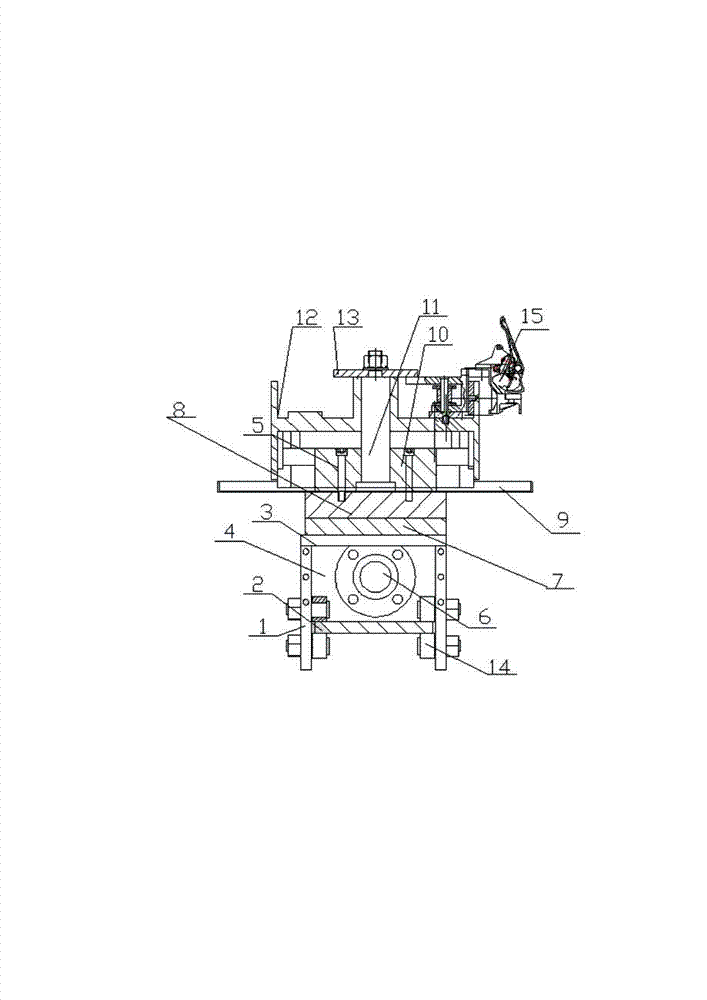

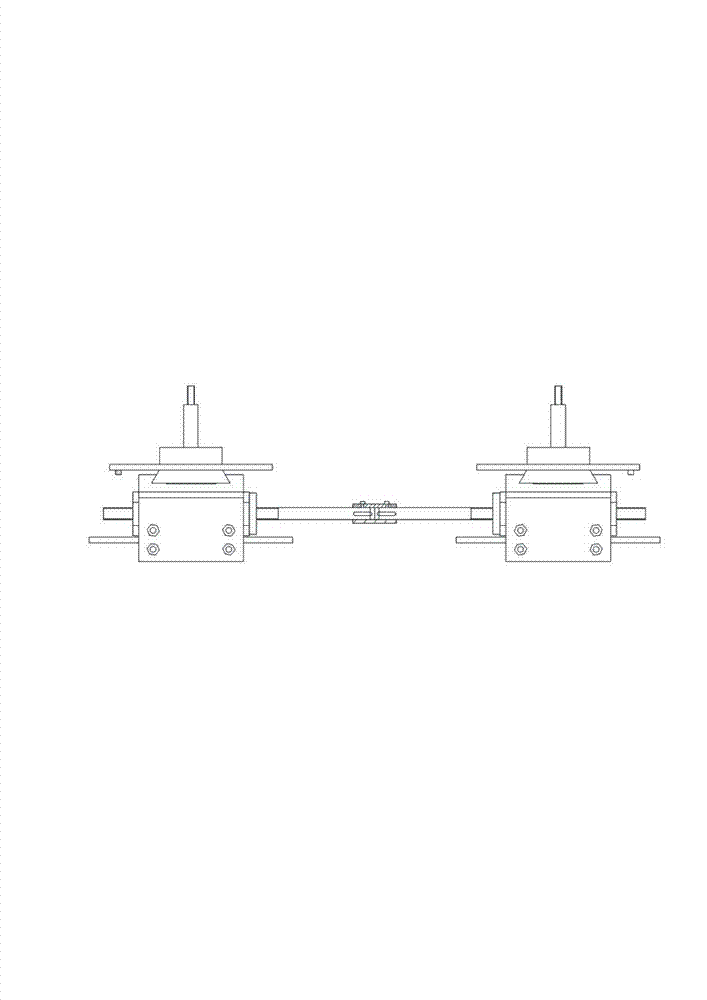

[0013] Such as figure 1 , 2 The special sliding seat for BOPET biaxially stretched sheets shown includes the left and right side plates 1 provided with rolling shafts 14, the guide plate 2 installed in the middle of the rolling shafts 14, the upper fixing plate 3 and the front fixing plate for fixing the left and right side plates 1 4. The rear fixed plate 5, the adjusting screw rod 6 installed in the center of the front fixed plate 4 and the rear fixed plate 5, the lower rail 7 installed on the upper fixed plate 3, the upper slide rail 8 installed on the lower rail 7, The oil receiving plate 9 installed on the upper slide rail 8, the positioning plate 10 fixed on the oil receiving plate 9, the positioning shaft 11 fixed on the positioning plate 10; the fixture guide rail 12 is fixed on the positioning shaft 11 through the pressure plate 13 And on the positioning plate 10.

[0014] The upper slide rail 8 and the lower slide rail 7 adopt dovetail groove type slide rails.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com