Method for inhibiting continuous hot-dip galvanizing and aluminizing unit coiling overflow edge

A hot-dip galvanizing and unit technology, applied in the direction of coiling strip, thin material handling, transportation and packaging, etc., can solve problems such as product defects, achieve the effect of improving surface smoothness, reducing product rejection rate, and suppressing overflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solution of the present invention will be further described in detail with a specific embodiment below.

[0026] In order to solve the problem that the existing hot-dip galvanizing aluminum unit causes serious product defects when the coiling overflows, a method for suppressing the coiling overflow of the continuous hot-dip galvanizing aluminum unit is proposed. The specific steps of the method are as follows:

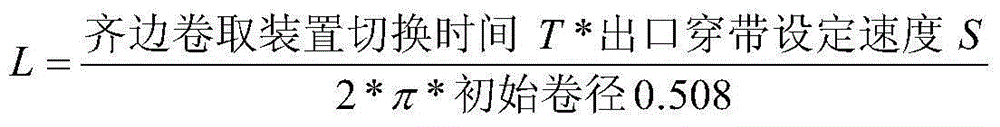

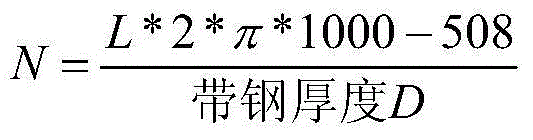

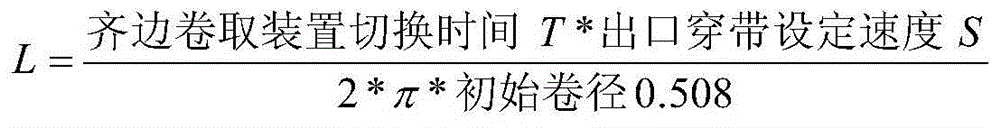

[0027] First, the exit section controller reads the switching time of the alignment coiling device from the centering mode to the automatic mode, the set threading speed of the exit section, and the thickness of the strip, and according to the switching time of the alignment coiling device, the exit Calculate the running length of the strip steel in the non-controlled state based on the set speed of section threading and the initial coil diameter, and calculate the number of coils wound on the coiler when the strip steel is in the non-controlled st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com