Air bag air suspension rear axle for passenger coach

A technology of air suspension and airbags, which is applied to suspensions, elastic suspensions, vehicle springs, etc. It can solve the problem of large space occupied by C-shaped beams, and achieve the effects of enhancing competitiveness, improving comfort, and reducing prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

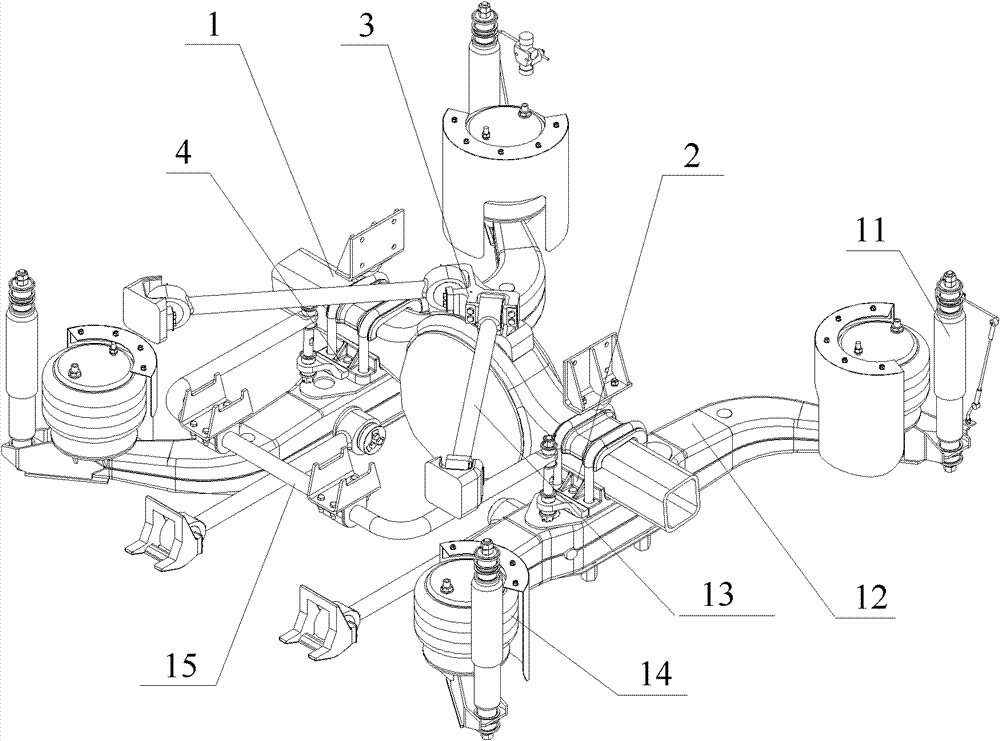

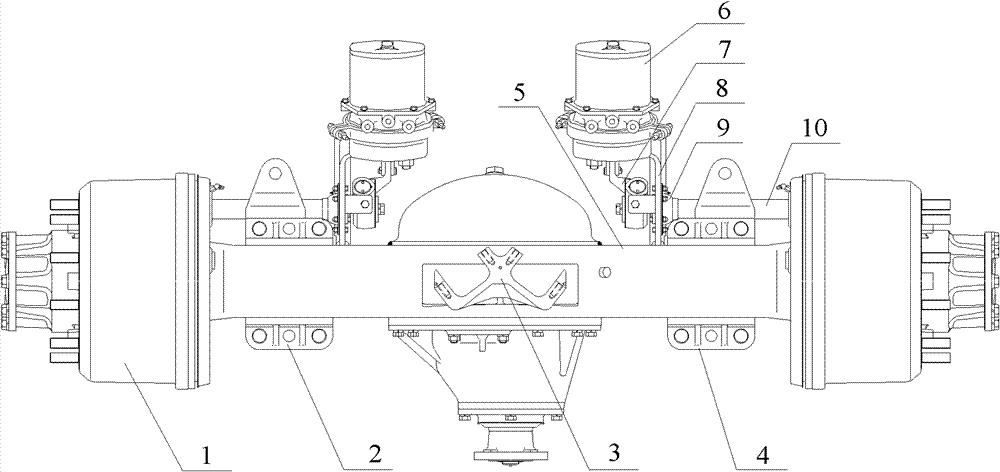

[0017] A passenger car with 6 air bag air suspension rear axle, its structure is as follows figure 1 , 2 As shown, it is characterized in that it includes the axle body 1, the left adapter seat 2, the thrust rod support 3, the right adapter seat 4, the axle housing 5, the brake air chamber 6, the adjustment arm 7, and the brake air chamber support 8. Joint bearing 9, camshaft 10, shock absorber 11, C-shaped beam 12, thrust rod 13, air bag 14, stabilizer bar 15, the square section of the axle body 1 where the leaf spring was originally placed is welded with left and right sides. The adapter seat 2 and the right adapter seat 4, the stabilizer bar 15 are respectively connected with the left adapter seat 2 and the right adapter seat 4, and the C-shaped beam 12 is fixed on the left adapter seat 2 and the right adapter seat 4 by bolts, The thrust rod support 3 is welded on the top of the axle housing 5 in the middle of the axle body 1, the thrust rod 13 is connected with the thrust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com