Manipulator

A manipulator, part of the technology, applied in the direction of manipulators, tubular objects, packaging, etc., can solve the problems of high labor intensity, low production efficiency, and many labors, and achieve the effect of high automation, high production efficiency and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

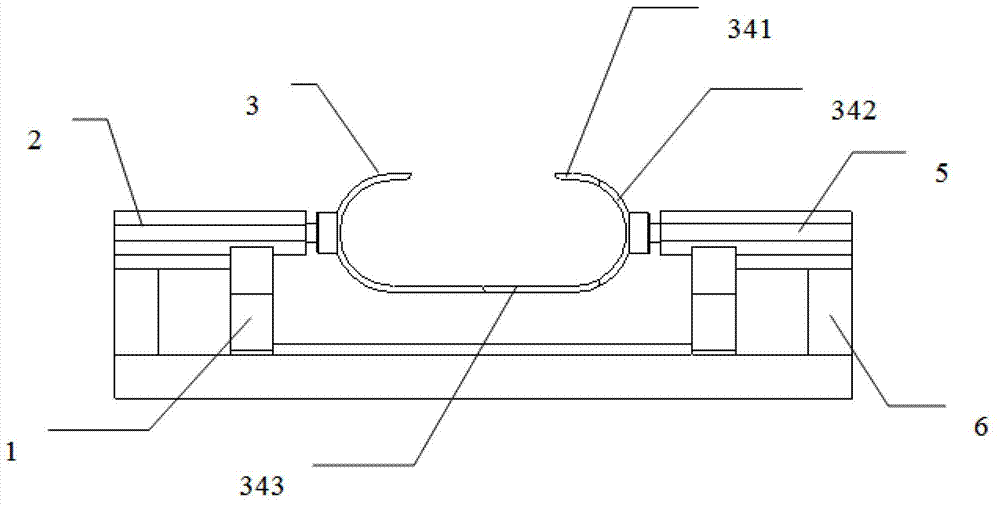

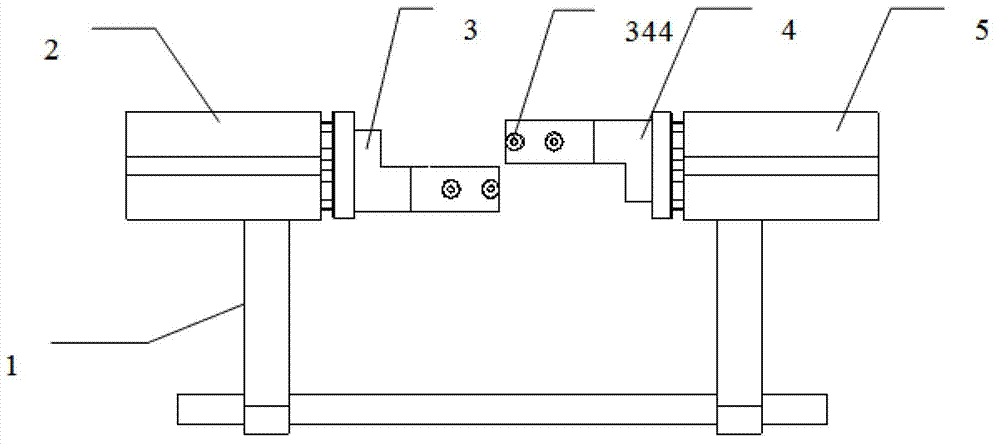

[0019] Such as figure 1 , 2 As shown, the present invention provides a kind of manipulator, comprises support bar 1, left draw in cylinder 2, right draw in cylinder 5, left manipulator 3, right manipulator 4, left manipulator 3 and right manipulator 4 are all formed by arc plate 342, lower nipper 343 and upper nipper 341, the lower nipper 343 and upper nipper 341 of the left and right manipulators are respectively connected with their respective arc-shaped plates 342, the lower nippers of the left manipulator 3 and the lower nippers of the right manipulator 4 are arranged alternately, the left The upper nipper of the manipulator 3 and the upper nipper of the right manipulator 4 are arranged alternately, the arc plate of the left manipulator 3 is fixed on the piston rod of the left retracting cylinder 2, and the arc plate of the right manipulator 4 is fixed on the piston of the right retracting cylinder 5 On the rod, the left retracting cylinder 2 and the right retracting cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com