Turnover hoisting tooling of water tube boiler body

A technology of water tube boilers and tooling, which is applied in the direction of transportation and packaging, load hanging components, etc., can solve the problems of high batch investment cost, many equipment safety factors, unfavorable production adjustment, etc., to reduce the site, facilitate production adjustment, and hoisting process Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

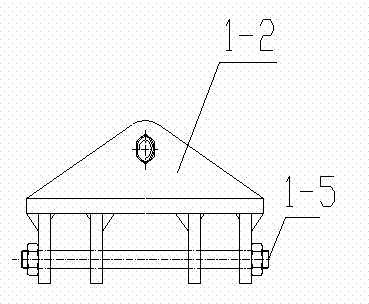

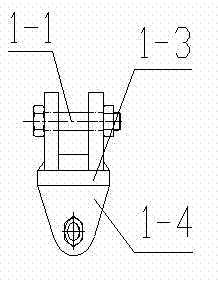

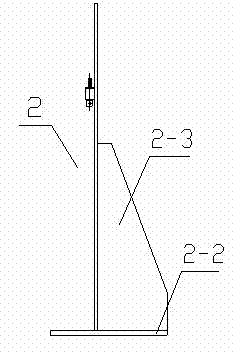

[0033] see Figure 1~4 , The water tube boiler body turning and hoisting tooling involved in the present invention includes two parts of a hoisting frame 1 and a support 2 .

[0034] The hoisting frame is placed on the upper part of the boiler body and connected with the lifting lug of the boiler body to provide an external force fulcrum for turning over and hoisting. There are several pieces of the hoisting frame 1, and each hoisting frame 1 is provided with a hanger beam 1-3, and the top of the hanger beam 1-3 is connected with an upper connection suspension plate 1-2, and the upper connection suspension plate 1-2 There are two or more pieces, two or more upper connecting hanging plates 1-2 are arranged in parallel, and two or more upper connecting hanging plates 1-2 are connected by lifting screw rod 1-1. The hoisting screw 1-1 provides hoisting fulcrum for turning over the boiler body and hoisting the hoisting rope; the bottom of the hanger beam 1-3 is connected with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com