Formula for toughening and enhancing outer wall of high-density polyethylene (HDPE) pipe

A formula and toughening technology, which is applied in the field of plastic pipes, can solve the problems of unbearable, waste, and cost increase for enterprises, and achieve the effects of improving elongation at break, simple production process, and improving impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

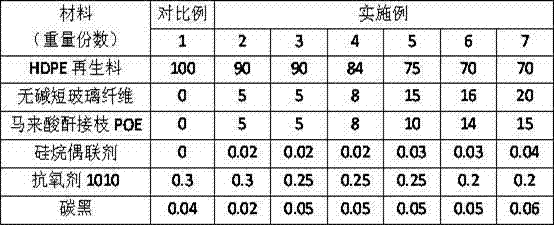

Image

Examples

Embodiment Construction

[0020] The present invention provides a toughening and strengthening formula for the outer wall of HDPE pipes. The formula is composed of the following materials in a certain proportion by weight: HDPE regenerated material, glass fiber, elastomer, coupling agent, antioxidant and toner.

[0021] In the invention, the coupling agent is firstly used to treat the surface of the glass fiber to enhance the tensile strength of the HDPE regenerated material. However, the tensile strength of glass fiber reinforced HDPE recycled materials is at the expense of the loss of elongation at break of HDPE recycled materials. In order to improve and increase the elongation at break of HDPE recycled materials, an elastomer with good compatibility with HDPE recycled materials is added to this formula. After adding the elastomer, it can initiate and terminate silver craze and absorb a large amount energy, so the impact strength has been improved. After adding antioxidant and toner, the ring rigid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com