Device and method for growing large-size high-temperature crystals by real-time adjustable temperature gradient method

A temperature gradient method, a technology for growing crystals, applied in the directions of crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the problems of poor single crystallinity, long crystal growth cycle, complex process, etc., and reduce the temperature in the furnace. Gradient, stable crystal growth interface, simple and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

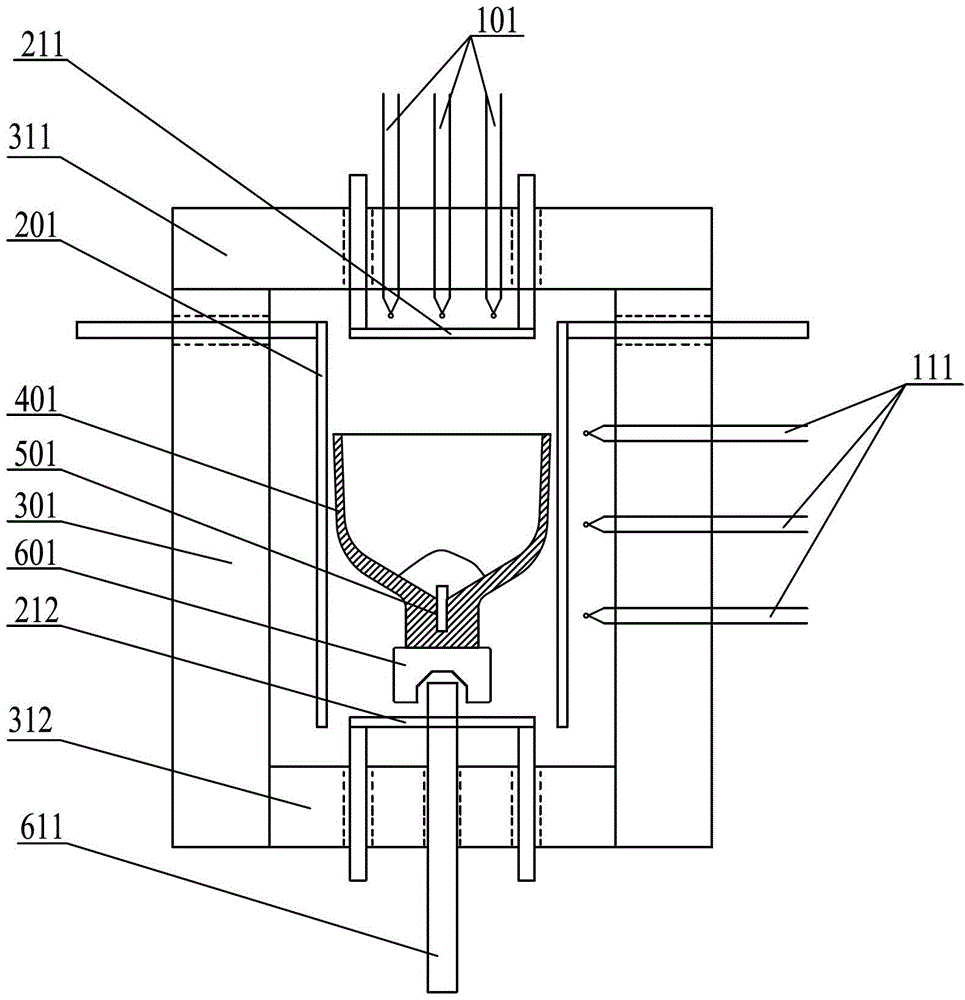

[0069] The temperature gradient adjustment method when using the above-mentioned device to grow calcium fluoride crystals is:

[0070] While keeping the temperature measured by the second thermocouple 111 located at the bottom and the power of the heating element 201 provided by the cylindrical high-temperature environment unchanged, the power of the heating element 211 is provided by reducing the upper growth gradient and increasing the lower growth gradient to provide the heating element The power of 212 can reduce the axial temperature gradient;

[0071] While keeping the temperature measured by the second thermocouple 111 located at the bottom and the power of the heating element 201 provided by the cylindrical high-temperature environment unchanged, the power of the heating element 211 is provided by increasing the upper growth gradient, and the lower growth gradient is used to provide the heating element. The power of 212 can increase the axial temperature gradient;

[...

Embodiment 2

[0077] The temperature gradient adjustment method when using the above-mentioned device for sapphire crystal growth is:

[0078] While keeping the temperature measured by the second thermocouple 111 located at the bottom and the power of the heating element 201 provided by the cylindrical high-temperature environment unchanged, the power of the heating element 211 is provided by reducing the upper growth gradient and increasing the lower growth gradient to provide the heating element The power of 212 can reduce the axial temperature gradient;

[0079] While keeping the temperature measured by the second thermocouple 111 located at the bottom and the power of the heating element 201 provided by the cylindrical high-temperature environment unchanged, the power of the heating element 211 is provided by increasing the upper growth gradient, and the lower growth gradient is used to provide the heating element. The power of 212 can increase the axial temperature gradient;

[0080] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com