Working device of synchronous transmission gear type loader

A working device and synchronous transmission technology, which is applied in the direction of mechanically driven excavators/dredgers, etc., can solve the problems of inconvenient lifting unloading height and unloading distance, and achieve the effect of increasing unloading height and unloading distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

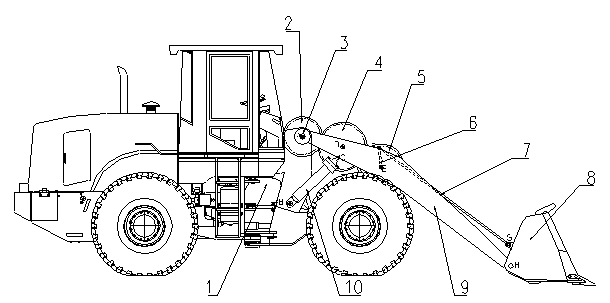

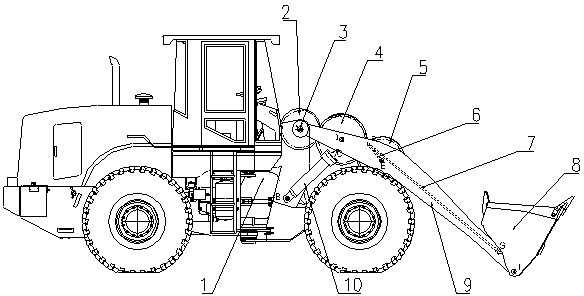

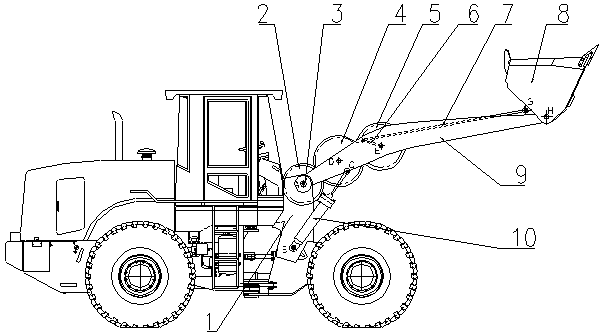

[0015] Such as figure 2 As shown in —5, the first gear 2 is locked, the boom cylinder 10 is kept locked, so that the boom 9 and the bucket 8 are fixed relative to the vehicle body, the loader vehicle body 1 moves forward, and the bucket 8 realizes loading state, such as figure 2 shown. Keep the boom oil cylinder 10 locked, and then drive the first gear 2 counterclockwise to rotate a certain angle around the mandrel 3, the third gear 5 also rotates counterclockwise due to the meshing relationship between the three gears, and the rocker on the third gear 5 The arm 6 also rotates counterclockwise, pulling the connecting rod 7 to make the parallel four-bar mechanism swing counterclockwise, and the bucket 8 realizes the end material state, such as image 3 shown. Lock the first gear 2, the piston rod of the boom cylinder 10 is extended, and the boom 9 is lifted with the bucket 8, the first gear 2, the second gear 4 and the third gear 5 form a planetary gear train, then the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com