Heat radiator

A heat dissipation device and self-radiation technology, which is applied in the direction of cooling/ventilation/heating transformation, etc., can solve the problems of small heat dissipation area of fin group, short time between airflow and heat dissipation fins, heat exchange, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

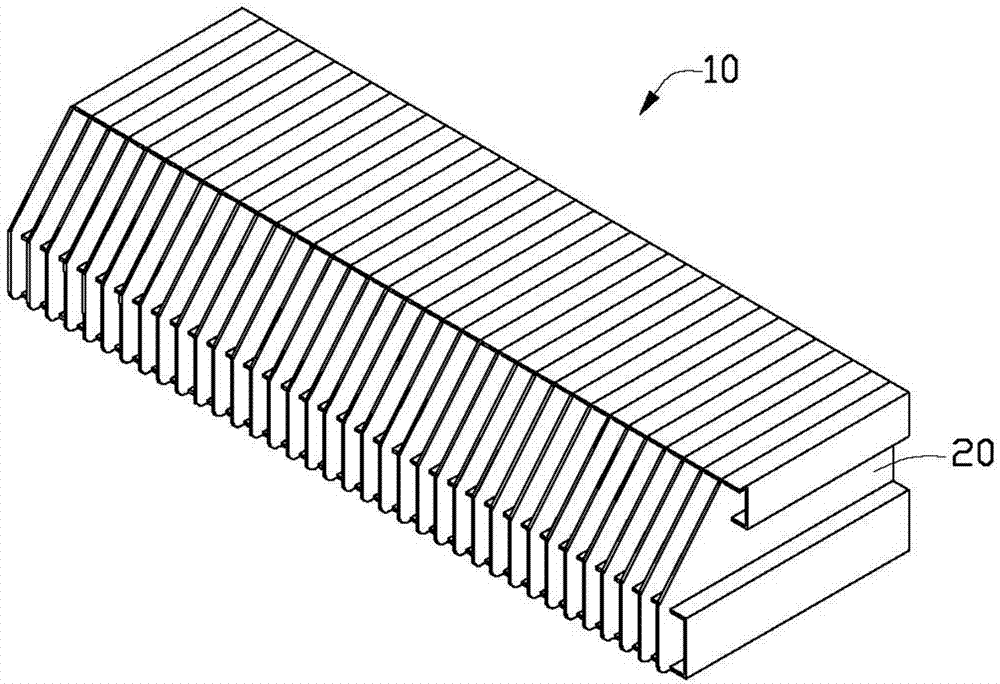

[0017] see figure 2 , shows a perspective view of the heat dissipation device 10 of the present invention, which includes several heat dissipation fins 20 . The heat dissipation device may further include a bottom plate (not shown) carrying heat dissipation fins 20 for contacting corresponding electronic components (not shown) to dissipate heat. The heat dissipation fins 20 abut against each other in parallel along the same direction to form the heat dissipation device 10 .

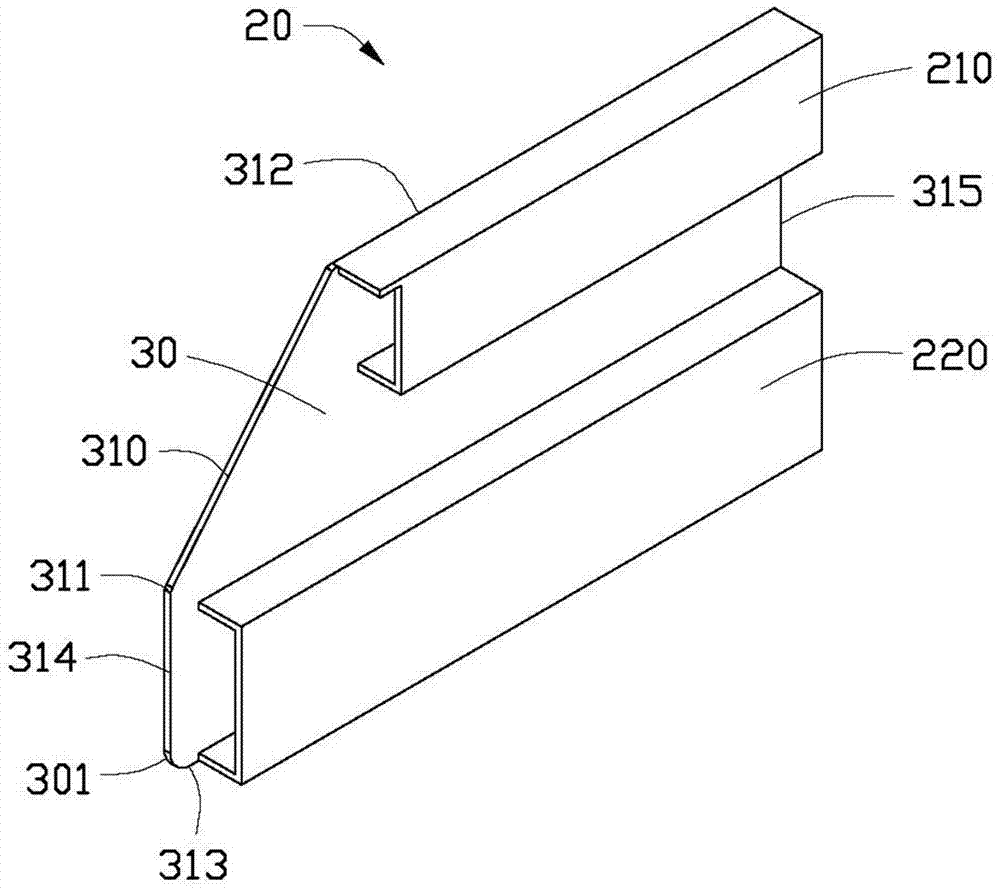

[0018] Please refer to 3-4 again, which shows an enlarged view and a front view of one of the heat dissipation fins 20 of the heat dissipation device 10 . The cooling fin 20 includes a body 30 , an upper flap 210 , and a lower flap 220 . The main body 30 , the upper flap 210 and the lower flap 220 are manufactured separately, and then fixed together by welding or other methods. The body 30 is a pentagonal metal plate, which is roughly a rectangle with one corner cut off. The upper border 312 of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com