Continuous fermentation case

A fermentation box and fermentation material technology, applied in feed, animal feed, animal feed, etc., can solve the problem of low fermentation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

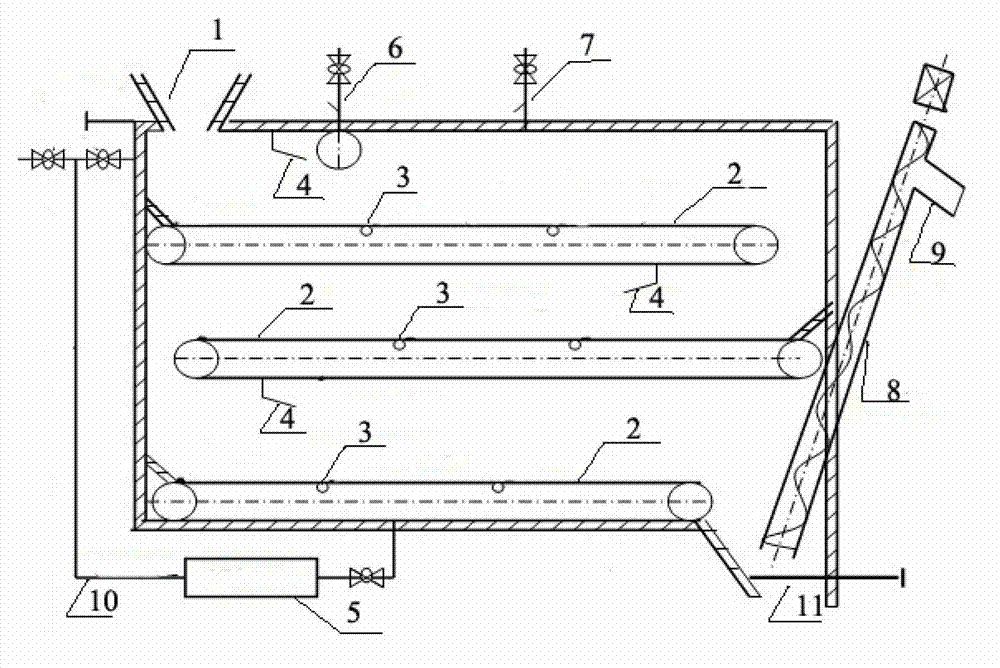

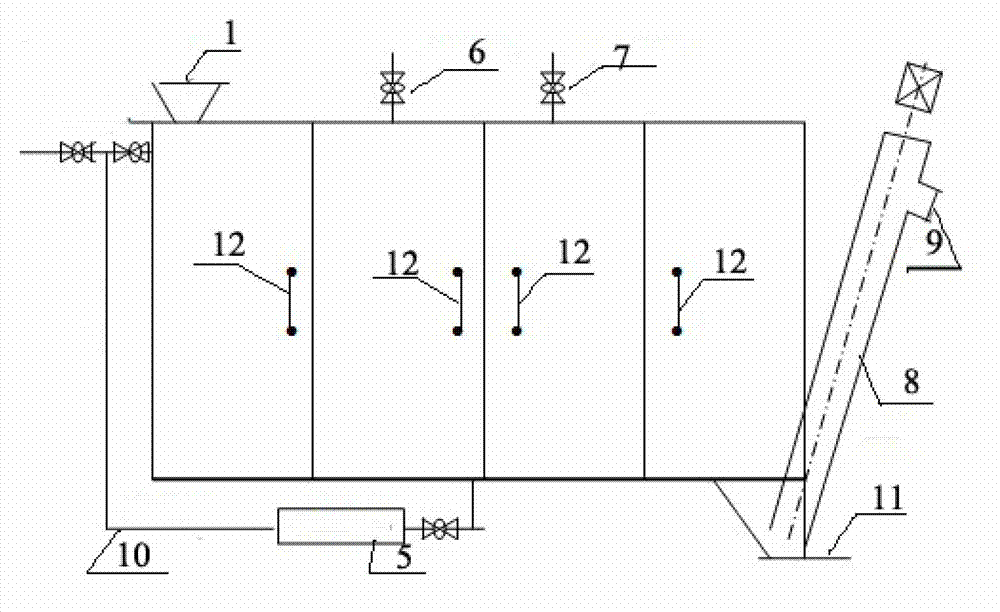

[0018] Embodiments of the present invention will be described below with reference to the drawings. The rapeseed meal is fed through the feed port 1, and falls into the fermentation material conveying device 2 due to gravity; the rapeseed meal is conveyed through the conveyor belt device 3 on the fermentation material conveying device 2 and passes through the material control scraper 4, and the material control scraper Plate 4 makes the thickness and shape of the fermented material uniform, and the rapeseed meal is evenly distributed in the fermented material conveying device 2; one-stage or multi-stage fermented material conveying device is selected according to the requirements of fermentation process conditions. When selecting a multi-stage fermented material conveying device, The material can be transported to the next-stage fermentation material delivery device through the conveyor belt device 3 on the fermentation material delivery device 2; according to the requirements ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com