Three-section cascaded fuzzy control method for blanking equipment of cooling bed in production line of continuous-rolling seamless steel pipes

A seamless steel pipe and production line technology, which is applied in the direction of rolling mill control devices, cooling beds, metal rolling, etc., can solve the problems of large number of detection components, fuzzy three-stage cascading, and increased equipment costs, so as to reduce the number of online and faults rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

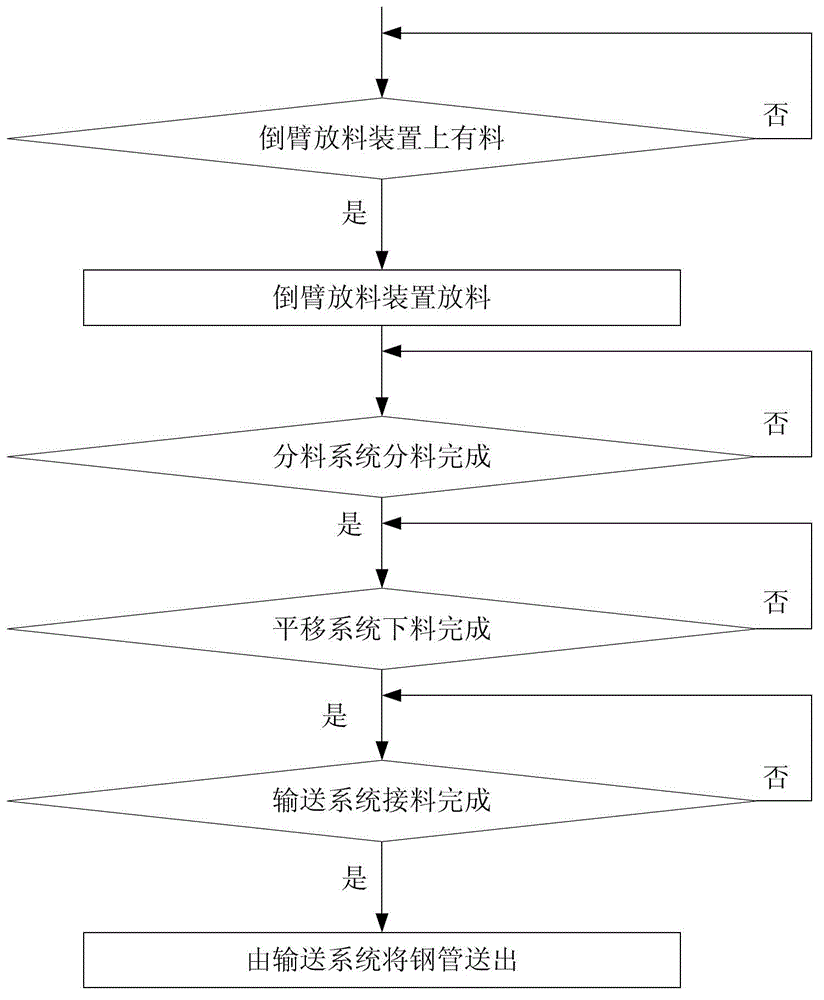

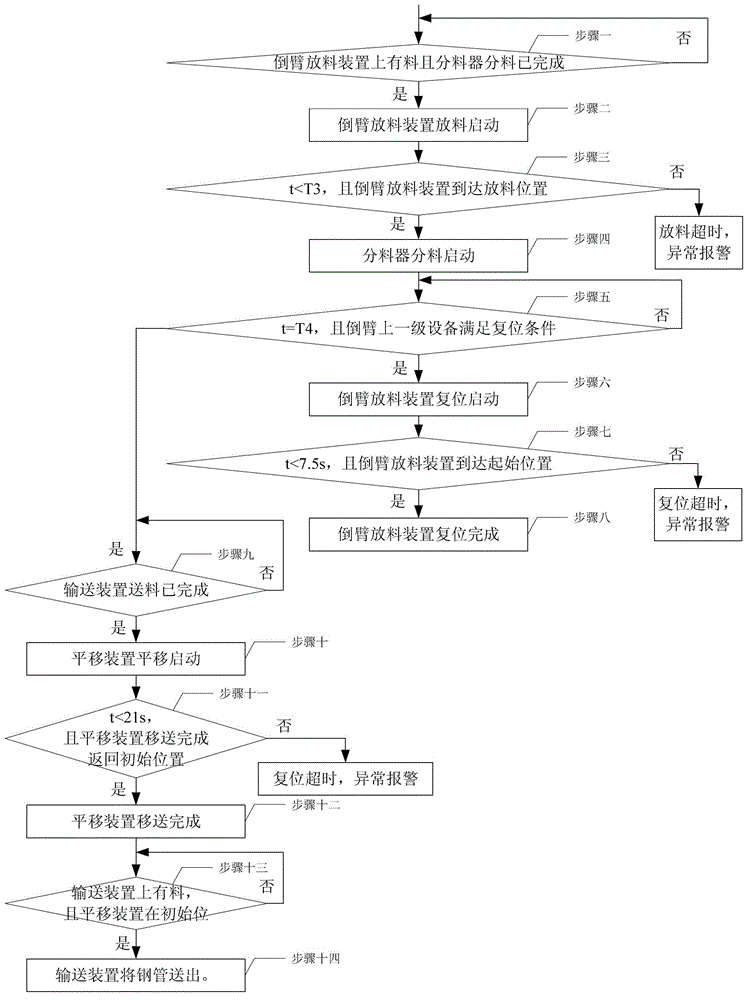

[0035] Specific implementation mode one: the following combination figure 2 Describe this embodiment, the three-stage cascading fuzzy control method of the cooling bed blanking equipment in the continuous rolling seamless steel pipe production line described in this embodiment, the method includes the following steps:

[0036] Step 1. Judging whether two conditions are met at the same time: there is material on the inverted arm feeding device; the material distribution by the distributor has been completed;

[0037] If the judgment result is yes, go to step 2; if the judgment result is no, go back to step 1;

[0038] Step 2: start the feeding of the inverted arm feeding device; then perform step 3;

[0039] Step 3. Judging whether two conditions are met at the same time: t

[0040] Among them, T3 is the time threshold of the "kinetic element" of the inverted arm discharging device, and T3=T1+T2,

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com