Forging method for flange type ball valve cover

A flange type, ball valve technology, applied in the valve device and other directions, to achieve the effect of beautiful appearance and uniform metallographic structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The invention is now described in detail in conjunction with the accompanying drawings.

[0026] 1. Select the blank. According to the different cross-section of the product, the blank should be a round bar with a diameter of 95mm and a length of 590mm;

[0027] 2. Heating, heating the round bar, using a 500KW-1000HZ medium frequency induction electric heating furnace, the heating time is 45s, and the heating temperature range is 1150±50°C;

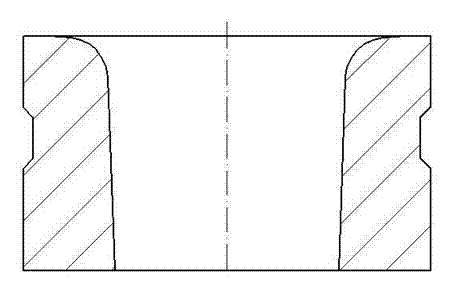

[0028] 3. The billet mold is made by using C41-75 air hammer. The temperature change during the operation should be figure 1 blanking mold shown;

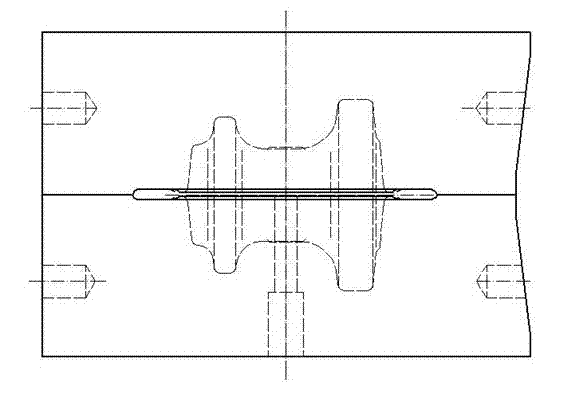

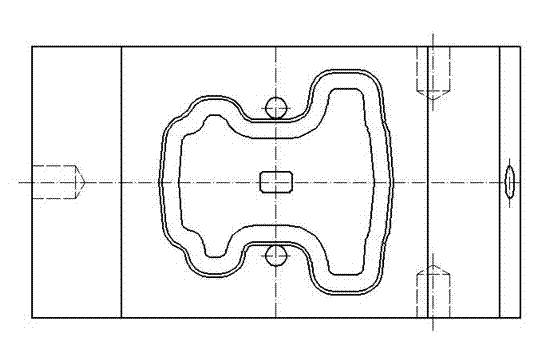

[0029] 4. Manufacture the pre-forging mould, use the blank mold made in step 3 to manufacture, the temperature change will be figure 2 and image 3 Block block shown;

[0030] 5. For preforming, a C41-75 air hammer must be used to make the pre-forging die obtained in step 4 into a blank, such as Figure 4 As shown, the first preform blank is obtained, such as Figure 5 As shown, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com