Method for processing large-tonnage large-diameter high-precision cylinder

A processing method and large-diameter technology, applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., to achieve the effect of eliminating influence, improving processing efficiency and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

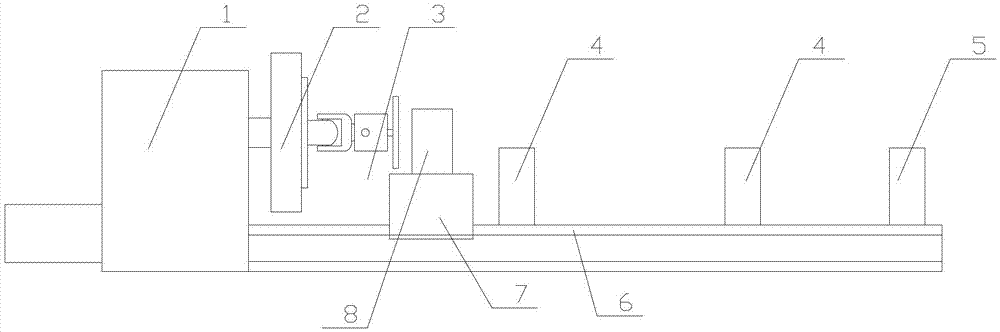

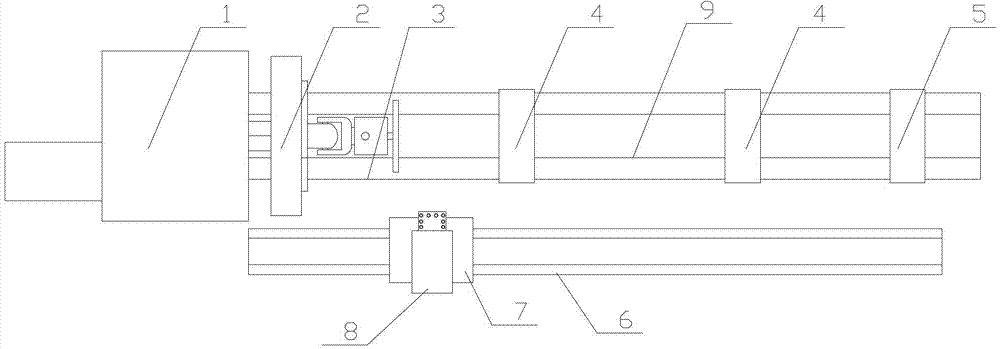

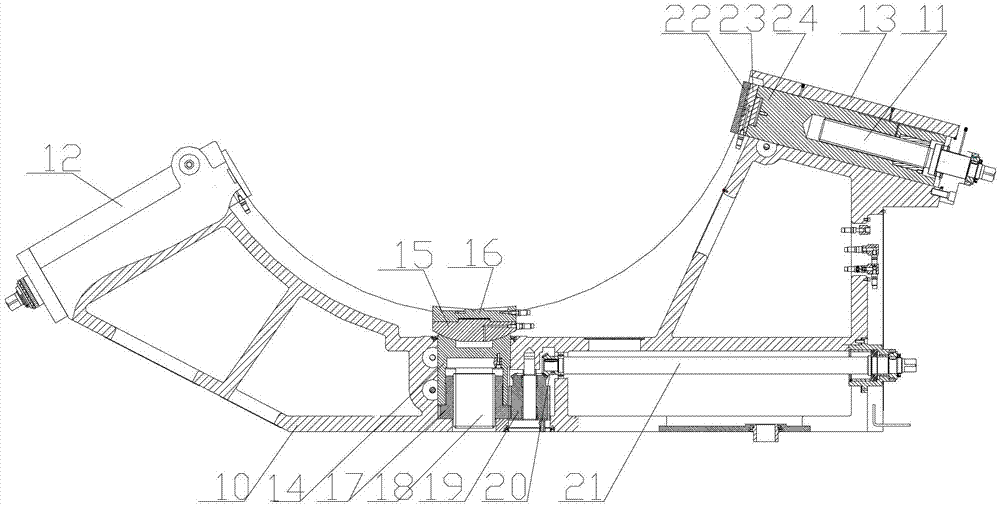

[0011] The present invention will be further described below in conjunction with accompanying drawing:

[0012] As shown in the accompanying drawings, the large-tonnage large-diameter high-precision cylinder processing method utilizes a large-tonnage large-diameter high-precision cylinder processing machine tool for processing. The large tonnage is more than 50 tons, the maximum diameter is more than 5 meters, and the height The precision is within 0.02mm. The large-tonnage, large-diameter, and high-precision cylindrical processing machine tool includes a tool rest bed 6 and a workpiece bed 9 arranged side by side on the foundation, one end of the workpiece bed is connected to the base of the headstock 1, and a faceplate is connected to the main shaft of the headstock 1 2. The faceplate 2 is connected with a universal joint 3, and the other end of the universal joint 3 is connected with the workpiece to be processed. The workpiece bed 6 at the other end of the workpiece is pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com