Residual resin discharge device of hot-runner injection mold equipment

A technology of hot runner injection molding and discharge device, applied in the field of residual resin discharge device, can solve the problem of increasing the amount of resin, and achieve the effects of cost reduction, simple resin replacement operation, and reduced resin consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

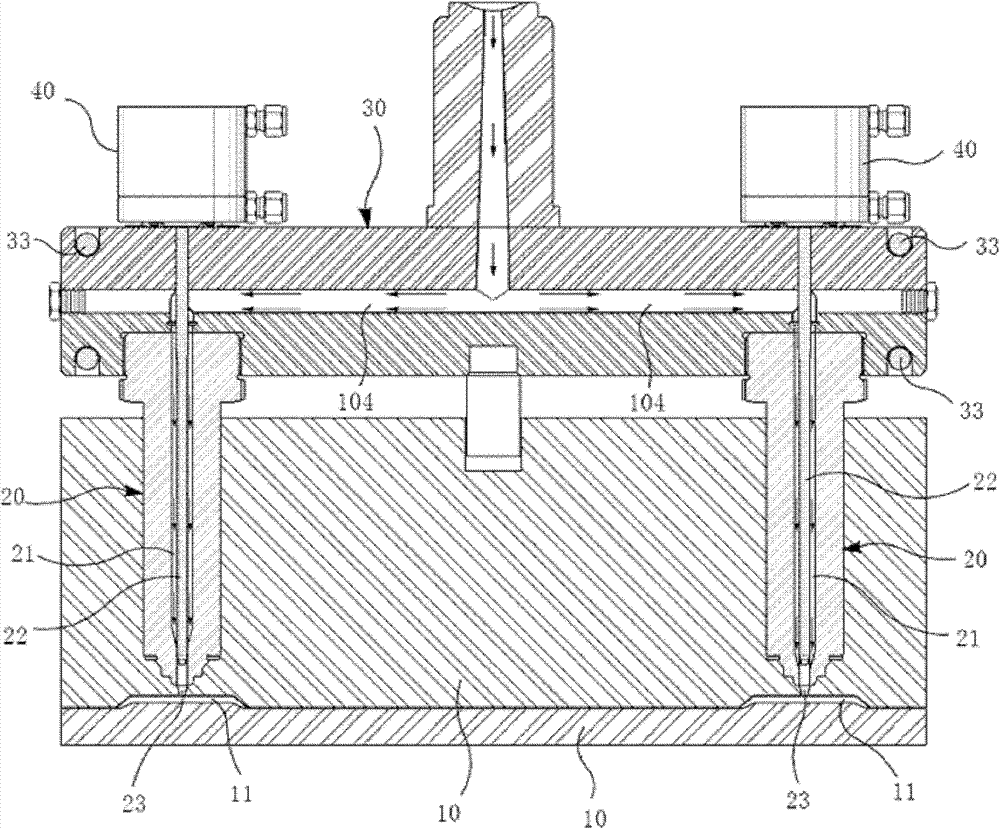

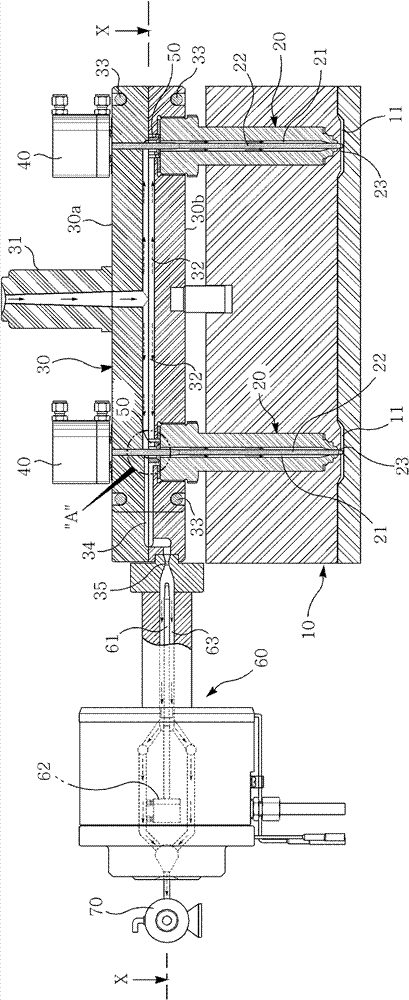

[0061] Figure 2 to Figure 5 It is the first embodiment of the present invention. The hot runner injection mold device of the first embodiment of the present invention includes a mold cavity plate 10 forming more than one cavity 11, a splitter plate 30 forming a plurality of runners 32, a nozzle 20 arranged in the cavity mold plate, and an inner valve for driving the nozzle. The needle 22 reciprocates to open and close the valve needle driving means 40 of the nozzle gate 23 and the molten resin supply means (not shown).

[0062] Such as figure 2 and image 3 As shown, the flow channel of the above splitter plate is composed of a plurality of flow channels 32 branched from the main gate 31, and the flow channels communicate with the resin channel 21 in the nozzle at each front position. When in use, the molten resin supplied by the molten resin supply device enters each flow channel 32 from the main gate 31 above the distributor plate, then flows into the resin channel 21 i...

Embodiment 2

[0077] Figure 6 to Figure 8 is the residual resin discharge device according to the second embodiment of the present invention

[0078] The remaining resin discharge device of the second embodiment is the same as the first embodiment except that the structure of the manifold is integrated and the resin separation and discharge device 50 is embedded in the nozzle coupling hole on the bottom surface of the manifold 30 . The description of the same components and their functions as those of the first embodiment will be omitted below. Also, the same drawing symbols are used for the same parts as those in the first embodiment.

[0079] The resin separating and discharging device 50 of the above second embodiment is as Figure 6 As shown, the nozzle setting hole of the distributor plate is embedded in the coaxial direction with the resin channel 21 of the upper nozzle 20, and the lower end is supported by the upper end of the nozzle provided by screwing. In this installed state,...

Embodiment 3

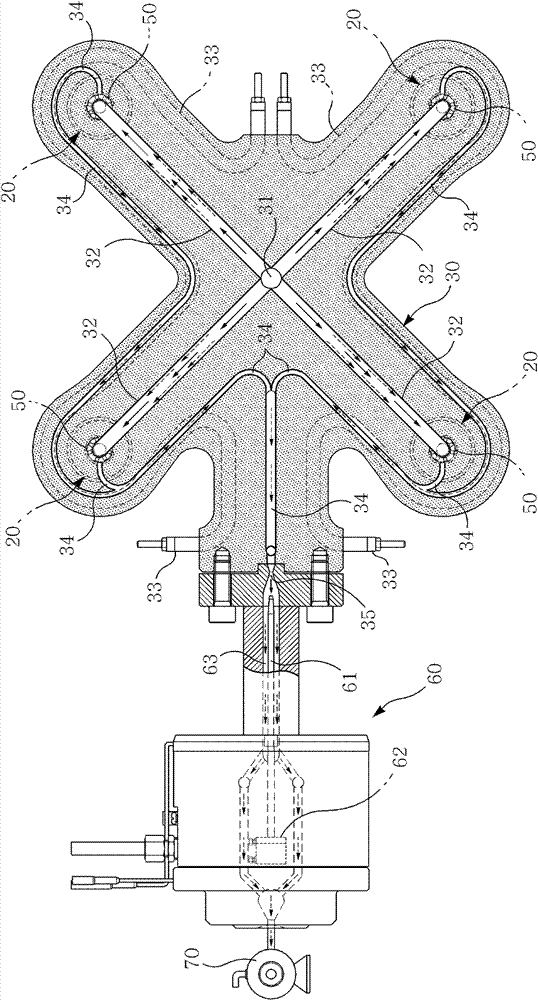

[0084] Figure 9 and Figure 10 is the third embodiment of the present invention. In the third embodiment of the present invention, a plurality of nozzles 20 are provided on the splitter plate 30 of the hot runner injection mold device, and each of the above nozzles 20 is connected with the runner 32 that the main gate 31 divides.

[0085] Each nozzle 20 uses the valve needle 22 raised and lowered by the valve needle driving device to open and close the gate as in other embodiments, and supplies or cuts off the supply of molten resin flowing through the runner 32 to the cavity.

[0086] The multiple nozzles 20 provided on the distributor plate above are formed by combining multiple nozzles, and each nozzle combination is formed by multiple (two in the embodiment) nozzles 20 .

[0087] These multiple nozzle combinations act either simultaneously or individually according to the injection molding process depending on the shape or structure of the injection molded product. In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com