Full-automatic film covering machine for tubes

A fully automatic, film-covering machine technology, applied in multiple packaging, packaging, transportation and packaging directions, can solve problems such as low efficiency, and achieve the effect of simple and reasonable structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

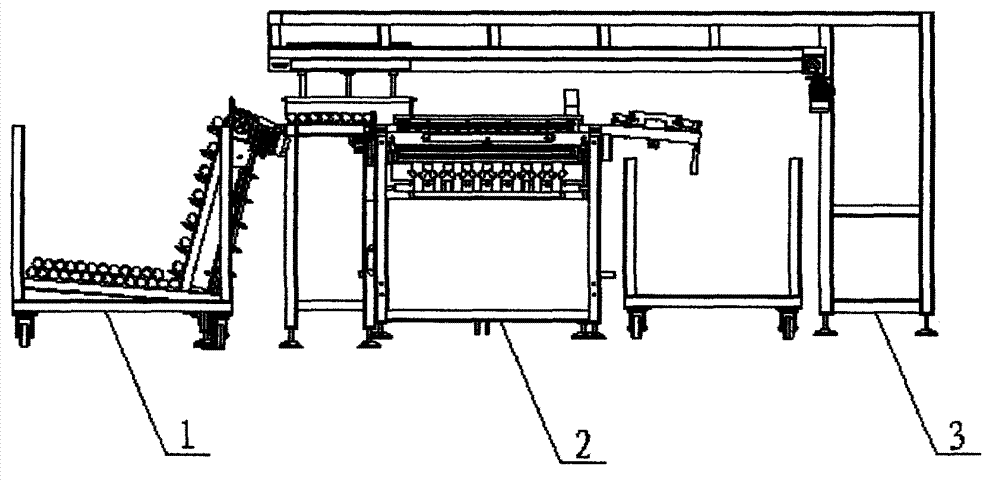

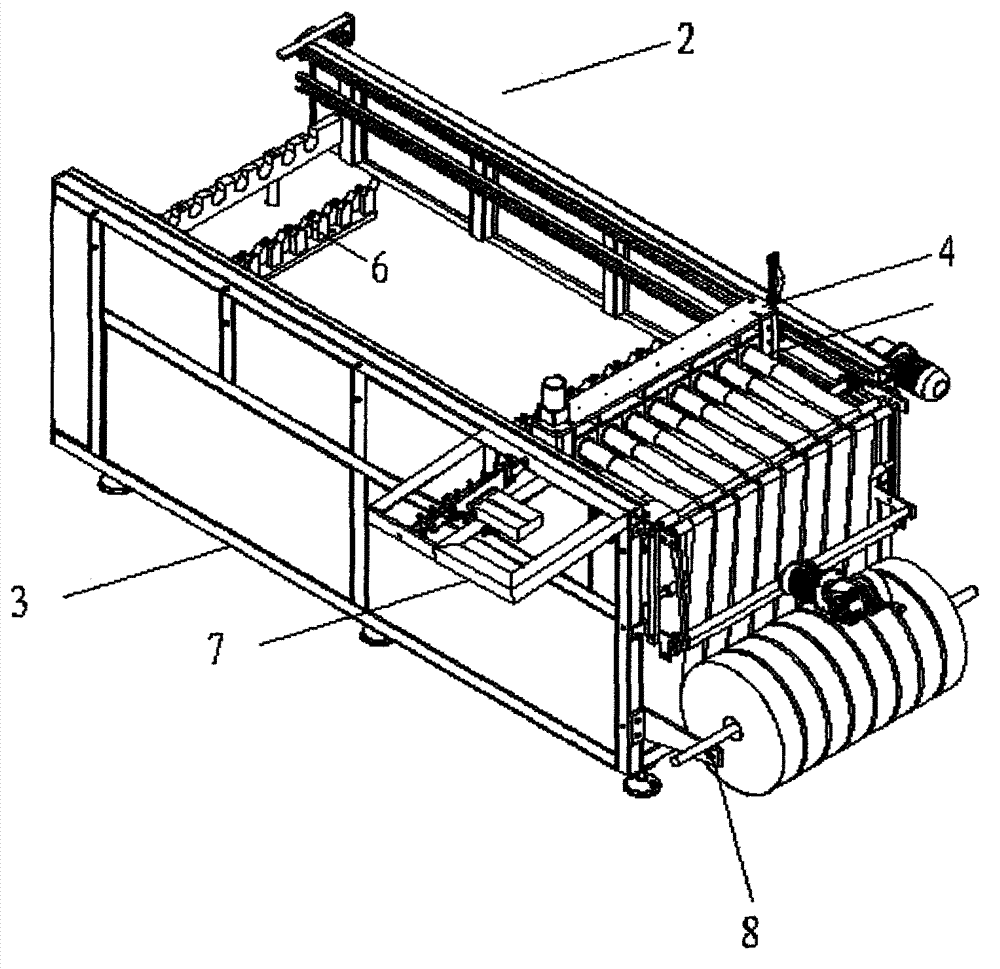

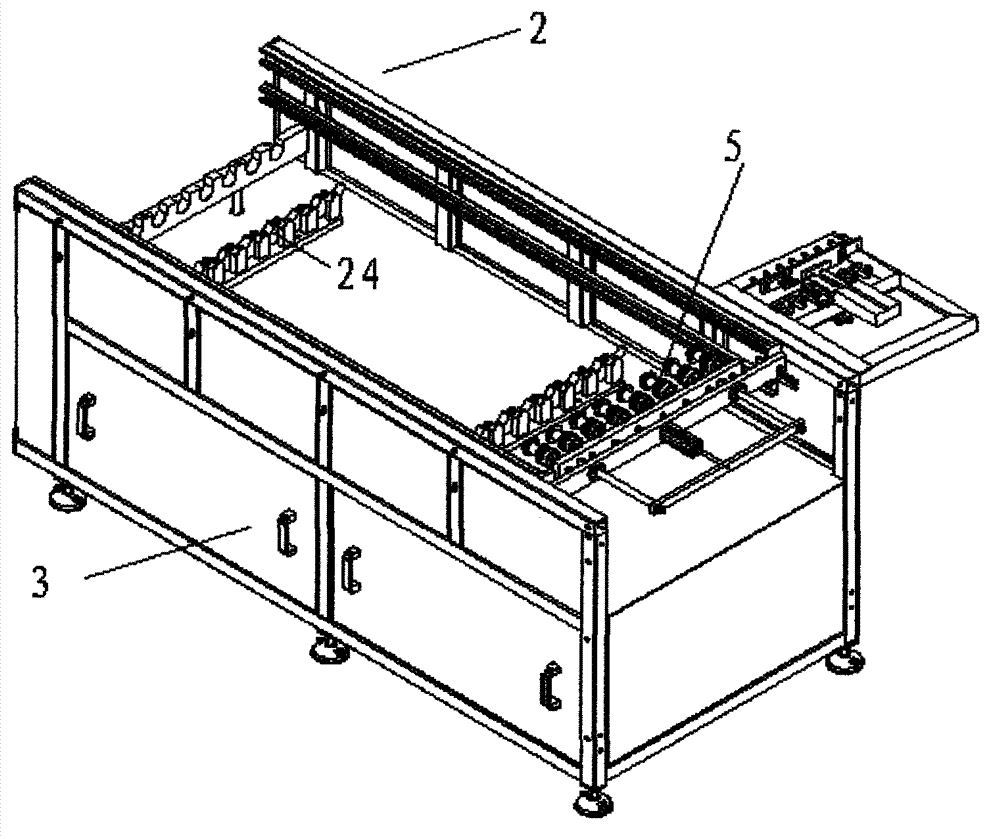

[0017] refer to Figure 1-Figure 6 , a full-automatic pipe casing machine, comprising a pipe loading machine 1, a packaging machine 2 and a pipe unloading machine 3, the packaging machine 2 comprising a frame 3, a packaging machine head 4, a film suction nozzle 5, a support frame 6, Folding device 7, conveying film device 8, described packing machine head 4 is made up of machine head left side plate 41, machine head right side plate 42, machine head upper plate 43, machine head lower plate 44, on machine head upper plate The machine portion of 43 is provided with induction deceleration motor 431, is all provided with belt clip 45 and some deep groove ball bearings 46 on the left side plate 41 of the machine head and the right side plate 42 of the machine head, on the upper plate 43 of the machine head and the machine head A driving shaft 47, a driven shaft 48 and a circular mold 49 with a pipe diameter slightly larger than the pipe material are installed between the lower plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com